Top 10 Tips for Efficient Yet Effective Root Cause Analysis

Efficient and Effective RCA

When performing a root cause analysis, which is more important? To be efficient or effective?

Actually, both are important because you need to be effective, but you don’t want to waste time. That’s why we made this list … The Top 10 Tips for Efficient Yet Effective Root Cause Analysis.

What happens if you don’t have an effective and efficient root cause analysis? Your company…

- Has recurring incidents and repeating investigations that weren’t done correctly in the first place.

- Wastes time on investigations that don’t produce significant lessons learned.

- Wastes effort on corrective actions that only address the symptoms and not the real root causes.

- Wastes management effort reviewing investigations and root cause analyses that are defective and therefore get rejected by management.

- Is cited by a regulator for poor investigations and inadequate root cause analysis.

- Has major fines or regulatory shutdowns over issues that could have been corrected earlier by applying good root cause analysis.

- Has a major accident that could have been prevented by good root cause analysis of precursor incidents.

That’s why efficient and effective root cause analysis is so important.

So, let’s start with the list and then explain each recommendation in more detail.

Top 10 Tips for Efficient Yet Effective Root Cause Analysis

- Be prepared for an investigation BEFORE the incident/accident happens.

- Assigning enough, but not too many, people to the investigation team.

- Sufficient training and practice for the investigation facilitators (team leaders) and the investigation teams.

- Use investigation team efficiency strategies.

- Get inside/outside help when needed.

- Don’t waste time on small problems that don’t provide significant lessons learned.

- Keep up-to-date on current investigation best practices.

- Use your TapRooT® Tools/Software effectively to improve efficiency and effectiveness.

- Get employees (not just team members) trained in the basics.

- Get management trained.

Let’s look at each of these recommendations individually…

1. Be Prepared

Before an accident or incident happens, you should prepare to have effective and efficient investigations. How do you do that? First, start by reviewing the resources in your TapRooT® Books.

Book 2, TapRooT® Root Cause Analysis Implementation, provides a checklist for implementing the TapRooT® System to achieve efficient and effective root cause analysis. But there is more. It includes Appendix A, A Sample Problem Reporting and Root Cause Analysis Guide, to help you develop your investigation policy. Also, it includes Appendix B, an Incident Reporting Form, to help collect initial information about an incident.

Another book to review is Book 7, TapRooT® Evidence Collection and Interviewing Techniques to Shapen Investigation Skills. Collecting and preserving evidence and conducting effective interviews provide the information you need to perform a root cause analysis. Book 7 includes information on:

- pre-planning for an investigation,

- emergency response,

- how to plan your investigation,

- developing an investigation kit,

- an initial observation form, and

- an interview preparation form.

All those topics are important when you are preparing for an investigation.

Note that these topics are included in the 2-Day TapRooT® Evidence Collection and Interviewing Techniques to Sharpen Investigation Skills Course.

Is that all you need to do to prepare? No. You will find more ideas in the following nine topics. So, keep reading!

2. Investigation Team

How many people should be on an investigation team? That’s a great question. The more people you have, the more people there will be to conduct the team’s work. But, the Team Leader will have to manage the team, keep everyone updated, and maintain consensus among the investigators. The more people on the team, the harder this job will be.

In general, we recommend no more than five team members. This is enough for all but the biggest investigations.

For really big investigations, you may decide to have a core team (maximum 10) and sub-teams for specific purposes (for example, analyzing the failure of a particular piece of equipment). These sub-teams can be thought of as an investigation within an investigation.

For small incidents, you should have a “team” of only one or two investigators. YES – one investigator can be the “team.” This makes your investigation of simple incidents efficient.

If your teams get too big, the team will waste tremendous amounts of time keeping everyone informed and reaching a consensus. This wasted time does not contribute to the quality of the investigation. That’s waste. And anybody that’s studied LEAN knows that waste needs to be avoided.

One more thing, you can have technical experts who contribute but who aren’t part of the team.

Now, who should be ON THE TEAM?

1. A Team Leader

2. Someone technically familiar with the process/work/equipment (depending on the blame orientation of the company, probably not someone who participated in the event)

3. Someone with influence/authority in the organization that will most likely have to make changes as a result of the investigation.

4. A contractor or union rep if contractors or union members are involved.

Note that one person could meet the first three of these criteria.

Also, note that every organization and every technical discipline at your company needs someone trained as a team member.

One final reminder … If you keep your teams to 5 or fewer people, you will increase the efficiency of your investigation dramatically. Going beyond 5 people starts an exponential increase in the coordination of team members.

3. Training

Let’s talk about training. Any professional knows that overtraining and practice helps a team achieve excellence when the pressure is on. Professionals at all levels (from the military to professional sports to highly educated experts) practice over and over again to finely hone “muscle memory.” The same should be true of your most prepared investigation team leaders.

Remember, the more serious the accident, the more the investigation team will be under pressure. Thus the more training and practice they need to produce exceptional results in difficult circumstances. A major investigation is not the time to learn the basics.

But even minor incidents can be a waste of time if an untrained or poorly trained team tries to find root causes.

Therefore to be prepared, think about OVER training your team leaders and team members.

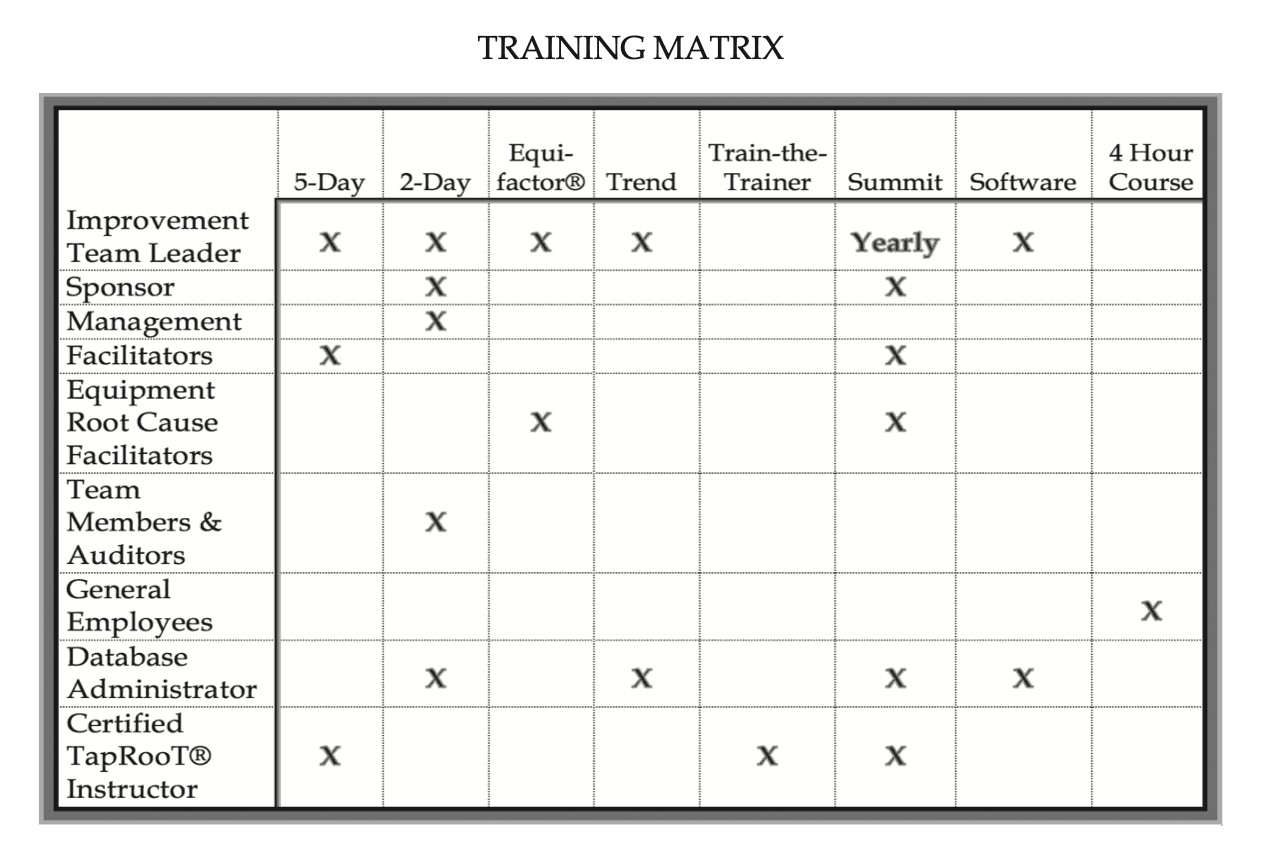

What training should the team leader and team members have? That’s covered in Book 2, TapRooT® Root Cause Analysis Implementation. Here is a snapshot of the training matrix from Chapter 3, Section 3.10, of the book:

Of course, this training matrix is explained in detail in Section 3.10 of Book 2. But a good start for all your experts is to attend the 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Course. You can have one of these courses at your site (contact us) or attend one of our upcoming public courses (see this link).

All team members should have attended at least a 2-Day TapRooT® Root Cause Analysis Course or the 3-Day Virtual TapRooT® Root Cause Analysis Course. To have one at your site, CONTACT US. Or if you just have a few people to train, have them attend one of our public courses.

If you plan to use Equifactor® and TapRooT® to investigate equipment failures and improve equipment reliability, you should send people to the 2-Day Equifactor Equipment Troubleshooting and TapRooT® Root Cause Analysis Course. See the upcoming public courses HERE.

Are you worried that the TapRooT® Training won’t provide your investigators with the training they need? Our courses are guaranteed:

Attend this course, go back to work, and use what you have learned to analyze accidents, incidents, near-misses, equipment failures, operating issues, or quality problems. If you don’t find root causes that you previously would have overlooked and if you and your management don’t agree that the corrective actions that you recommend are much more effective, just return your course materials/software and we will refund the entire course fee.

So don’t worry. Our training is effective.

For a list of all our courses and webinars, see THIS LINK.

One more thing you might have noticed in the matrix above is that each year, we hold the Global TapRooT® Summit. This is a great place for your team leaders to

- Learn new best practices,

- Network with their peers from other companies,

- Meet experts and learn new skills.

- Refresh their investigation skills

CLICK HERE to learn more about the next Global TapRooT® Summit.

4. Efficiency Strategies

Team Leaders need to think about efficiency during investigations. What tools keep a team efficient? Try these…

- Use the SnapCharT® to plan the investigation (planning reduces needless effort).

- Schedule interviews to efficiently collect information and to minimize interviewers’ and interviewees’ time.

- Use no more than two investigators to perform an interview.

- Don’t waste time doing things in team meetings that could be done by one individual outside the team meeting (for example, redrawing a SnapCharT®).

- Pause the investigation and let people get back to their normal jobs if analyses or information is delayed/won’t be available for a period of time.

- Keep an investigation “to-do” list and a meeting “to-do” list to keep the investigation and meeting on track.

- Let the investigation team know that you, the team leader, and management are interested in investigation efficiency and effectiveness. Track the hours spent and find out why activities are taking longer than planned.

- Make sure that there is sufficient management support for an investigation. Investigators cooling their heels waiting for people to interview, fights with contracts over support purchase orders, or the inability to get a meeting room to use as the “war room” for the investigation team should not occur or should be “solved” by management support. The main investigation challenge should not be overcoming bureaucratic obstacles.

- Have administrative assistance available for the team. Copying or other administrative tasks should be handled by the appropriate staff.

Practicing these tools will make teams more efficient.

5. Get Help When Needed

The investigation team needs to know when to get help. Have pre-planned assistance available for:

- Metallurgical analysis

- Oil analysis

- Human factors analysis

- Outside expert facilitators

- Accident reconstruction

- Technical equipment experts

- Computer data retrieval experts

Once upon a time, companies had their own internal experts. Now, most of this expertise has been outsourced. Make sure that you plan to get this expertise when you need it. (Get contracts in place before an accident happens.)

6. Don’t Waste Time on Small Problems That Don’t Provide Significant Lessons Learned

We all know that investigating precursor incidents (defined here) is an important part of any improvement program. Your investigation policy should provide basic guidance on which incidents deserve an investigation. Also, we provided additional guidance on which precursor incidents to investigate in this article:

For low-to-moderate risk incidents, we created a process to simplify precursor incident investigation (see Book 3, Using the Essential TapRooT® Techniques to Investigate Low-to-Medium Risk Incidents).

The simplified 5-Step Process starts simplifying the investigation by only using the essential TapRooT® Tools. But the biggest savings come at Step 2.2 – deciding if you should continue the investigation after you have collected some basic information and drawn a SnapCharT® Diagram. Stopping an investigation where there isn’t a significant lesson to be learned is a great way to improve investigation efficiency without losing important lessons learned.

7. Keep Up-to-Date

You don’t want to get behind the times in your investigation technology. I had a person talking to me the other day who was still using the 1996 version of the TapRooT® System. Yes, this was a good tool, but we have made it so much better in the three major revisions since 1996. I explained that he really needed to keep up to date.

One way that we already mentioned to keep up to date is to attend the Global TapRooT® Summit. But there’s more…

First, ask yourself … Do you have the complete set of the most recent TapRooT® Books? See this link:

https://store.taproot.com/books

Next, watch our free TapRooT® TV Videos live on Facebook at noon on Wednesdays (Facebook Link) or on our YouTube Channel (TapRooT® TV).

Next, you can join one of our webinars. See: https://store.taproot.com/courses#sFilters=9!89

Or you can register for and read our weekly newsletter. Use the link at the bottom of this page.

Also, before every Global TapRooT® Summit, we have a special set of courses. For more info, CLICK HERE.

Finally, we conduct on-site or virtual refresher training. CONTACT US to schedule a course.

That’s a great list of ways to keep your root cause analysis skills updated!

8. Use Your TapRooT® Tools/Software to Improve Efficiency and Effectiveness

Most suggestions above assume you are using the TapRooT® System and Software to perform your root cause analysis. But if you aren’t, now is the time to consider upgrading your root cause analysis to be more efficient and effective. For more about the advantages of using TapRooT® Root Cause Analysis, watch this episode of 21st Century Business…

If you are already using TapRooT® Root Cause Analysis, maybe you should consider ways to be more effective. For example, you could attend one of our webinars. See the complete upcoming list HERE.

9. Get Employees Trained

How much more effective would your investigations be if the people you are “investigating” – employees in general – understood what you were doing and why you were doing it? If they understood that this investigation wasn’t the blame game? If they understood the development of a SnapCharT® and how the Root Cause Tree® led to fixable root causes that would help them perform their work more efficiently?

That’s why you should consider training all employees on root cause analysis. Contact us about having a 4-hour general employee root cause analysis course by CLICKING HERE.

10. Management Training

There is nothing worse than performing a difficult investigation and then having management fail to understand the lessons learned because they don’t understand root cause analysis and performance improvement methods.

The ultimate inefficiency is having to rewrite an investigation report and add ineffective, or worse yet – counterproductive, corrective actions dictated by management.

- Have you seen management mandate punishment when the investigation didn’t call for it?

- Have you seen management insist that smaller problems should be investigated even though they didn’t meet the investigation criteria?

- Have you seen management insist there is a bad trend when there is way too little data to detect a trend?

- Have you seen management spend millions of dollars fixing problems that don’t exist?

Root cause analysis and performance improvement training for management is probably one of the best investments in time and $$$ that a company can make. Why don’t more companies have management root cause analysis training? Because the managers don’t think they need it or they don’t have the time.

We can add short, custom management courses to your already scheduled on-site course for employees at your facilities and help managers have a better understanding of root cause analysis and their role in performance improvement. We can even conduct the courses VIRTUALLY. CONTACT US to develop a custom course for your managers.

11. Bonus Idea…

Proactive improvement is much more efficient than reactive improvement.

If targeted correctly, using TapRooT® Tools proactively is the most effective/efficient strategy that a company can adopt to improve performance. If you are truly interested in the efficiency of improvement, consider becoming more proactive with your use of TapRooT®. See Book 6, TapRooT® Root Cause Analysis for Audits and Proactive Performance Improvement, to learn more about using TapRooT® proactively in audits. Or attend a 2-Day Auditing & Proactive Improvement Using TapRooT® Course. See the upcoming public courses HERE.

That’s It

There are Top 10 Tips (plus one bonus) to make your investigations more efficient and effective. We hope that you will use at least some of these ideas to improve your root cause analysis efforts. And if you would like to speak to one of our TapRooT® Implementation Advisors, call us at 865-539-2139.