The Equifactor® Equipment Failure Troubleshooting Process

A Troubleshooting Process

To paraphrase Johnny Cash, to achieve equipment performance excellence, you must learn from equipment failures and make sure they don’t become repeat equipment failures.

The following information about the Equifactor® Equipment Failure Troubleshooting Process is from the book, Using Equifactor® Troubleshooting Tools and TapRooT® Root Cause Analysis to Improve Equipment Reliability by Ken Reed and Mark Paradies.

It is copyrighted material and is used here with the authors’ permission.

Types of Failures

There are three types of equipment failures. They are:

- Failures that don’t require troubleshooting.

- Failures that just require troubleshooting.

- Failures that require troubleshooting and root cause analysis.

Let’s explain the three types.

Failures that Don’t Require Troubleshooting

The first type of failure is very simple (like a burned-out light bulb). It doesn’t require troubleshooting or root cause analysis. You just replace the bulb. You don’t need a book or troubleshooting tools to do that.

But what if the bulb keeps burning out every day? Then you have a problem. The frequency of the failure is too high. You need to find out the cause behind the repeat failures. It is time for troubleshooting.

Failures that Require Troubleshooting

If the failure is somewhat beyond the simple example (a burned-out bulb) but does not have serious consequences, the equipment troubleshooter may apply just the equipment troubleshooting techniques described in Chapter 4 of the book without applying the entire TapRooT®/Equifactor® process. This is the second type of failure.

Failures that Require Troubleshooting and Root Cause Analysis

Other examples of the need for troubleshooting techniques and root cause analysis are when failures have unacceptable consequences. For example:

- The failure is part of a significant environmental release.

- The failure leads to a serious injury or fatality.

- The failure causes major plant downtime.

- The failure causes unacceptable quality issues.

- The failure is expensive (equipment damage, repair costs, …).

- The failure keeps happening over and over again.

In these cases, management may want a thorough investigation of what happened, and the entire Equifactor® Troubleshooting and TapRooT® Root Cause Analysis processes will be applied. That’s the third type of failure.

Develop Guidance for The Analysis Needed

Your department or company should develop guidance for field personnel on the types of failures that require no troubleshooting, simple troubleshooting, and troubleshooting plus root cause analysis. Then you can keep things simple by just applying the tools that you need.

Guidance for the level of investigation to apply in different circumstances is provided in the book: TapRooT® Root Cause Analysis Implementation, Appendix A, by Mark Paradies & Linda Unger, Copyright 2017 by System Improvements, Inc., Knoxville, Tennessee.

Troubleshooting + RCA First Step – Find Out What Happened

The first step in any investigation is to find out what happened. In an equipment failure, this starts with troubleshooting and drawing a preliminary SnapCharT® of the sequence of events leading to the failure. Those are the first two steps in the process outlined above.

Below is an example preliminary SnapCharT® of an equipment failure…

Troubleshooting a Failure

Troubleshooting is where you use the tools in the Equifactor® Troubleshooting System. These tools include the Equifactor® Equipment, Manual Valve, Component, and Electrical Troubleshooting Tables; Failure Modes; and Failure Agents (FRETT). The tools are organized in the Equifactor® Troubleshooting Guide shown below.

The guide and tools provide a systematic process to troubleshoot an equipment failure and find the information needed to develop an effective repair.

Below is a section of an Equifactor® Troubleshooting Table from the TapRooT® Software for the symptom of short bearing life on a centrifugal pump.

The information gained using a troubleshooting table (or any other troubleshooting tool) is added to the SnapCharT® to provide a complete understanding of what happened. That information helps with the next step … deciding if you need to continue (is this a type 2 failure with no root cause analysis required or a type 3 failure with root cause analysis required).

Deciding to Continue

Some equipment failures are serious enough that you will want to perform a root cause analysis. Some are trivial, and a simple replacement of the part or equipment is all that is needed.

In this step, you decide how much effort (none or more) you will expend finding the failures’ root causes. The decision is based on your judgment. You need to decide if there is something of value to learn by expending the effort needed to find and fix the failure’s root causes. The guidance developed by your company (mentioned above) can help with this decision making process. By now you should know if…

- The failure is part of a significant environmental release.

- The failure leads to a serious injury or fatality.

- The failure causes major plant downtime.

- The failure causes unacceptable quality issues.

- The failure is expensive (equipment damage, repair costs, …).

- The failure keeps happening over and over again.

If you decide that there is nothing more to learn, you stop the analysis and simply repair the equipment. If you decide this incident is one of the types mentioned above, you will want to continue and perform a root cause analysis.

Finding Causal Factors

If you proceed to this step, you have decided that there is more to learn. The first step of this learning process is identifying the equipment failure’s Causal Factors.

By this point in the process, you have developed an “Incident” (the circle on your SnapCharT® Diagram). You will learn that the circle is the worst thing that happened during the sequence of events. Often, the Incident is more serious than the equipment failure. It could be:

- Loss of production

- More extensive equipment damage

- Environmental release

- An explosion or fire

- An injury or fatality

Thus, Causal Factors may include actions that go beyond simple equipment failure and may include issues related to human performance. That is why Book 5 goes beyond the Equifactor® Troubleshooting System and includes the essential TapRooT® Root Cause Analysis System Techniques.

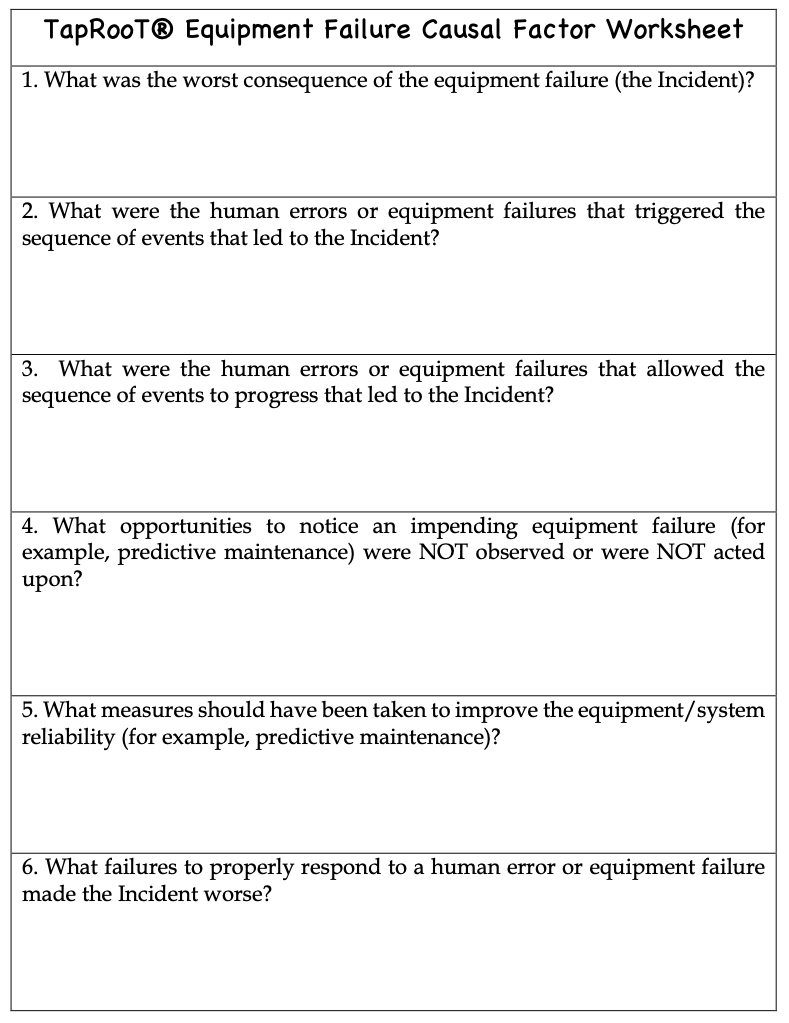

At this point, you would use one of the three Causal Factor Worksheets to identify the Incident’s Causal Factors. The simple Causal Factor Worksheet used to analyze an equipment failure is shown below.

This worksheet is discussed in more detail in the TapRooT® RCA Training.

Finding Equipment Failure-Related Root Causes

The next step in the TapRooT® Process is finding the specific root causes for each Causal Factor. To do this, you use the TapRooT® Root Cause Tree® and Root Cause Tree® Dictionary.

The Root Cause Tree® is a systematic analysis tool to guide you to the root causes of human performance and equipment-related root causes. Book 5 provides detailed information about using the Root Cause Tree® to find root causes. This information is also covered in the 2-Day TapRooT® Root Cause Analysis Course.

Developing Fixes

The “fix” referred to in this step is not just replacing a component. The fix refers to the corrective actions needed to address the specific root causes and keep them from repeating. Thus, these fixes eliminate the causes of the failures (both human and equipment performance-related) that allowed the failure to occur.

The book details how to develop these effective fixes using the Corrective Action Helper® Guide

or Corrective Action Helper® Module of the TapRooT® Software.

Repair Equipment

This is the step that most technicians are the most familiar with. However, in this case, we may need to address the root causes of the failure and implement all, or some, of the corrective actions developed in the previous step IF we performed a root cause analysis.

If you decided there was nothing more to learn, this step might simply replace the failed part, component, or equipment.

This step, including simple ways to decide how many corrective actions need to be implemented before repairing the equipment, is detailed in Book 5.

Complete

That’s it! You have completed the “troubleshooting” and even proceeded to the follow-up steps. This completes the use of the Equifactor® Troubleshooting and TapRooT® RCA Tools and helps you develop a much more comprehensive and successful plan to improve your equipment’s reliability. Now that you have a good overview of the troubleshooting and repair process, would you like to learn more?

1-Day Equifactor® Equipment Troubleshooting and 2-Day TapRooT® Root Cause Analysis Training

There are three courses that you can attend to learn about Equifactor® Troubleshooting and TapRooT® Root Cause Analysis.

1. The 1-Day Equifactor Training + 2-Day TapRooT® RCA

To learn about the Equifactor® Troubleshooting Tables, Change Analysis, and drawing a SnapCharT® Diagram, you can attend the 1-Day Equifactor® Equipment Troubleshooting Training.

Would You Like To Attend?

The next public 1-Day Equifactor® Course is coming up on November 14 in Houston, Texas. This course is followed up with a 2-Day TapRooT® Root Cause Analysis Course for those who would like to learn Equifactor® Troubleshooting and then learn to use the TapRooT® System for Root Cause Analysis.

You can also schedule this course at your site. Call us at 865-539-2139 for a quote and to get your training scheduled.

2. 2-Day Equifactor® Troubleshooting and TapRooT® Root Cause Analysis Course

We have a 2-Day Equifactor® Equipment Troubleshooting and TapRooT® Root Cause Analysis Course coming up on April 24-25, 2023, near Houston, Texas. It is being held as one of the pre-Summit Courses (see Summit info below). CLICK HERE to register.

3. 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Training

The 5-Day TapRooT® Training includes a section on the Equifactor® Troubleshooting Techniques. If you are an investigator of major incidents/accidents, this is the course for you. See the upcoming public 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Courses at THIS LINK.

But There Is MORE – The Summit!

There is a track in the upcoming 2023 Global TapRooT® Summit titled the…

Equipment Reliability Track

What is the Equipment Reliability Track all about? Ideas to help you improve equipment reliability and asset performance. Hear how Equifactor® Equipment Troubleshooting Users have reached new levels of equipment performance. Learn how to conduct cross-discipline troubleshooting and apply equipment troubleshooting best practices. And hear equipment reliability expert Heinz Block share his decades of experience achieving world-class equipment reliability.

This track is the perfect combination with the pre-Summit 2-Day Equifactor® Equipment Troubleshooting and TapRooT® Root Cause Analysis Course (April 24-25). Save $300 when you attend both.

The track includes the following Best Practice Breakout Sessions:

Session 1 – Equifactor® Success at Tucson Electric | Gary Gardner

Session 2 – Cross-Disciplinary Troubleshooting | Ken Reed

Session 3 – Supercharging Reliability | Justin Clark

Session 4 – Equifactor® Symposium | Ken Reed & Justin Clark

Session 5 – Heinz Block Shares Equipment Reliability Best Practices (Part 1) | Heinz Block

Session 6 – Heinz Bloch shares Equipment Reliability Best Practices (Part 2) | Heinz Bloch

Session 7 – Building a Roadmap to Success | Rick Hulse

Session 8 – Swimming Upstream: Real-World Troubleshooting | Mark Olson

Session 9 – Change Analysis Exercise | Justin Clark

Plus our amazing Keynote Speakers.

Just click on the figure below for more information.

Register for the 2-Day Equifactor® Course and the Summit and SAVE $300 by CLICKING HERE.

Greetings,

I would like take this course.

I would like to know, is it online?

How much is the cost?