What will you learn in Ken Reed’s TapRooT® Equifactor® Course in Houston? Last Chance to Register!

In the Houston course, participants will learn to use the Equifactor® Process to troubleshoot equipment issues/incidents and find out what is causing failures.

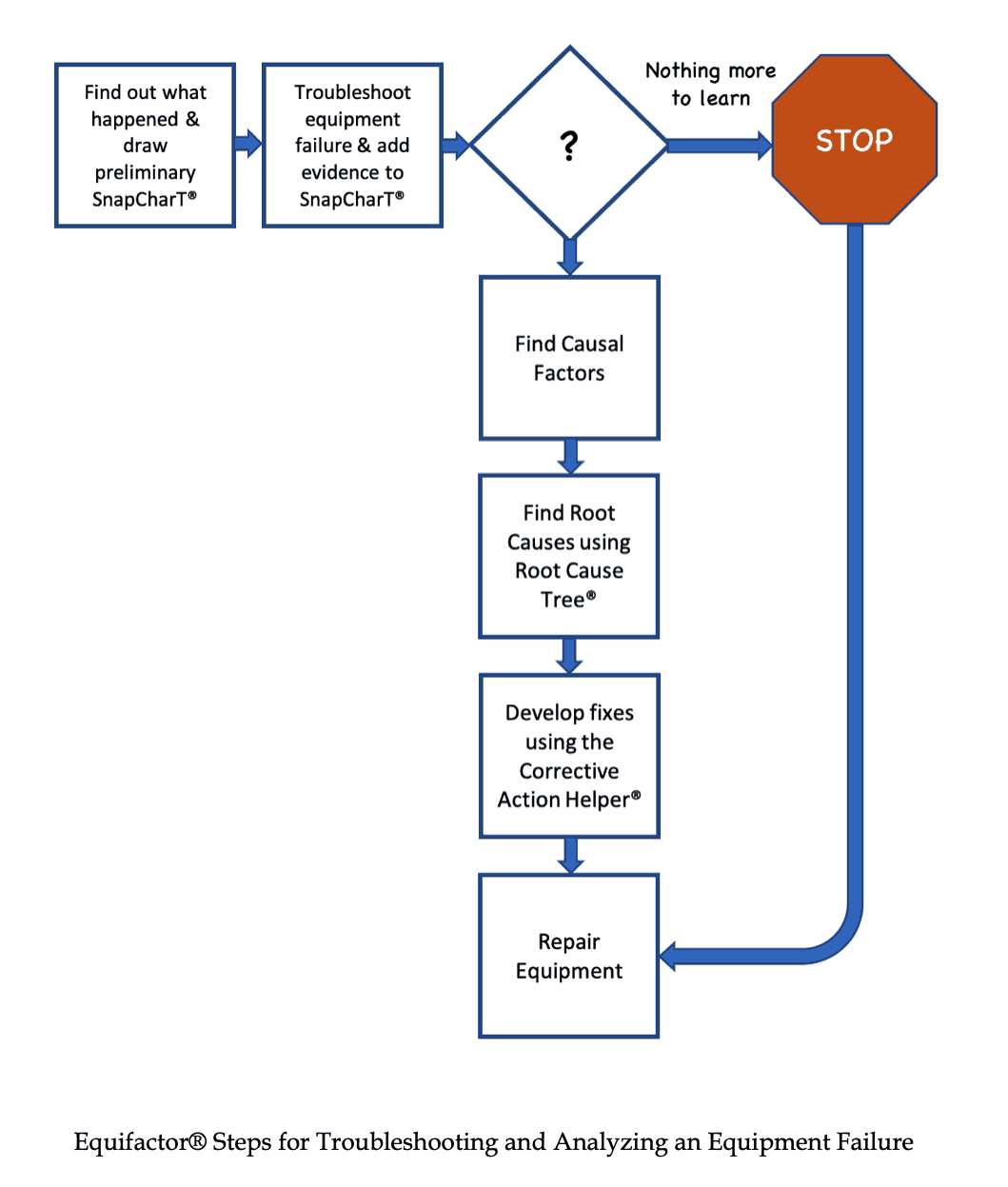

The TapRooT® Equifactor® course begins with the nuts and bolts of Equifactor®. In the Equifactor® course, you’ll learn to use the TapRooT® System to collect and organize information related to an incident; to identify the Causal Factors of the incident, and to find the fixable root causes of the incident.

Register your team now for Ken Reed’s Equifactor course in Houston, Texas, November 3-4, 2021.

You’ll have plenty of interaction with course participants and the instructor(s), including breakout sessions and the focus on the SnapChart® exercise.

The SnapChart® is a mission-critical tool that helps you understand and work through what happened that caused the incident to occur.

Listen as TapRooT® Instructor Tim Diggs and Implementation Strategist Benna Hughes give you critical advice on building a complete SnapCharT® so you and your team will have the foundation for a solid, successful investigation.

Equifactor® Techniques are based on the work of noted equipment reliability expert Heinz Bloch

The tools can be used by maintenance personnel, equipment reliability specialists, maintenance managers, or investigators who don’t have an extensive understanding of equipment engineering.

Equifactor® learners and users are equipped with powerful, proven, customizable up-to-date tools

- Equifactor® Troubleshooting Tables – a systematic guide to troubleshooting common equipment problems.

- SnapCharT® Diagram – visualize and organize the information you collect to make what happened understandably.

- Root Cause Tree® Diagram and Dictionary – find the real, fixable root causes of human performance and equipment issues.

- Corrective Action Helper® Module – provides suggested corrective actions to help you develop effective fixes.

- Safeguard Analysis – helps define Causal Factors and develop effective corrective actions.

- Change Analysis – collect and understand information about problems caused by changes or differences in system, equipment, or people.

Note: When you register for the course, materials provided include the above tools list as well as the book, Using Equifactor® Troubleshooting Tools and TapRooT® Root Cause Analysis to Improve Equipment Reliability.

From the get-go, the course outline informs learners about the methodology that will train them

Day one

- Class/TapRoot® Introductions

- Understanding What Happened

- SnapCharT® Exercise

- Collecting Information

- Equifactor® Basics: Failure Modes & Failure Agents

- Equifactor® Basics: Troubleshooting Tables

- Human Errors

- Process Troubleshooting

- Seawater Pump Example

Day two

- Equifactor® Software

- Identifying Causal Factors

- Using the Root Cause Tree®

- Root Cause Tree® Walkthrough Exercise

- Root Cause Tree® Class Exercise

- Change Analysis

- Final Exercise – Putting What You Have Learned to Work

After the course, students in the course receive a certificate of completion and a 90-day subscription to TapRooT® VI Software, the dynamic cloud-based software that computerizes Equifactor® and TapRooT® Techniques.

Register your team now for Ken Reed’s Equifactor course in Houston, Texas, November 3-4, 2021.

Need help registering or have questions? Call us at 865.539.2139. Email us if you’d like to have a course taught at your company’s site.