What Vision for Root Cause Analysis Does Your Company Have?

The following is copyrighted material based on Chapter 1 of the book: TapRooT® Root Cause Analysis Leadership Lessons about the vision for root cause analysis. It is used here by permission of the copyright holders.

Vision

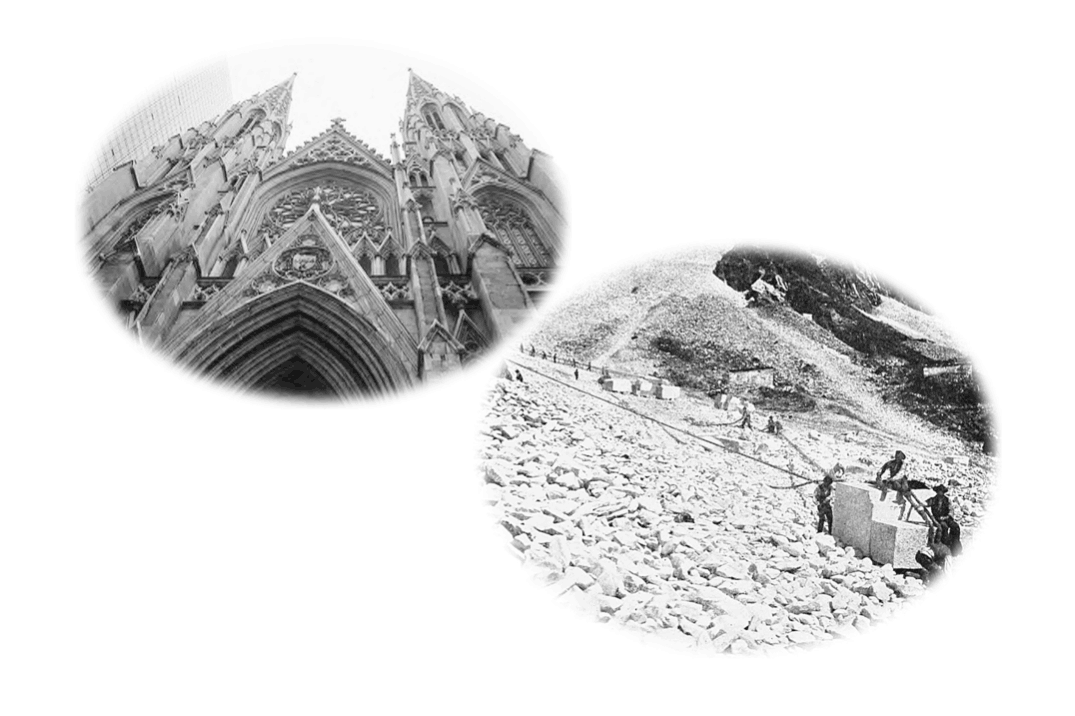

There were three men laboring in a field of rocks.

Each one is asked what he is doing.

The first man says, “Can’t you see, I’m breaking rocks?”

The second man replies, “Can’t you see, I’m earning my salary?“

The third man answers, his eyes gleaming with enthusiasm,

“Can’t you see, I’m building a cathedral!”

Fable, Source Unknown

We see three basic visions for improving performance:

1. The Crisis Management Vision

2. The Blame Vision, and

3. The Opportunity to Improve Vision

Just one of these visions leads to sustainable, long-term improvement. Yet, it is NOT the most prevalent vision. This provides a great opportunity. Sustained, revolutionary improvement is possible if the correct vision and tools for performance improvement are chosen. Therefore, anyone interested in optimizing performance improvement must understand the three visions and the tools they need to find the real root causes of performance problems.

Read on to learn about all three visions and what your company should do…

The Crisis Management Vision

We’ve heard many managers express the Crisis Management Vision. They say:

“We don’t have time to thoroughly investigate this problem.

We just need to get past the crisis and get back to business as usual.”

They don’t have the time or the inclination to find a problem’s real root causes. Instead, they use the same old corrective actions that they have always used. They try something fast and easy. They:

• Counsel the operator to be more careful.

• Require more training.

• Write (or rewrite) the procedure.

Sometimes they do all three to show how committed they are!

Unfortunately, this type of corrective action usually doesn’t work (even though sometimes it may appear to work). The problem happens again. The vicious cycle of crisis and crisis management repeats itself. And everyone complains about having to work too hard because they are always in “crisis mode.”

Why does this type of vision sometimes appear to work?

First, there’s plenty of activity. If one equates activity with progress, then it looks like we must be progressing.

Second, in many cases, the odds of having a problem are low. So even if your corrective actions are totally useless, it appears that they work because the next time the job is performed, the mistake does not reoccur. Why? Because the odds of failure were low (let’s say only 1 in 100). So the odds of two failures in a row are unlikely (just 1 in 10,000).

The mathematical terminology for this is “regression to the mean.” The mean performance was successful. After an incident, performance returns to success even if nothing is changed. So in the Crisis Management Vision, it seems like the fast and easy (useless) corrective action worked when the incident does not immediately repeat. Our focus changes to the next crisis. When the problem eventually repeats, we don’t remember the old incident and apply more of the same fast and easy corrective actions. If we do remember the old incident, we blame the repetition on complacency. Obviously, the best corrective action for complacency is to tell people to try harder!

This Crisis Management Vision clearly does NOT lead to sustained, long-term improvement. But people are busy. Eventually, crisis after crisis may lead to the Blame Vision.

The Blame Vision

We’ve seen managers caught up in the Blame Vision. They believe: “If we could just get people to be careful and try harder, these problems would go away.”

These managers think they can weed out the bad, lazy, or careless employees or discipline them to get them to work harder and smarter. These managers see problems as obviously the fault of the person doing the work. If the worker was more careful, then he/she would have opened the correct valve. If the surgery team was more careful, they would have amputated the correct leg. The only problem for people with this vision is finding the right person to blame. Once that person is identified, he or she can be disciplined (fired?), and then we can get back to business as usual.

The Blame Vision seems to be embedded in human nature. Perhaps it started with the legal system’s adversarial insistence on finding the guilty party. However, when this vision is used on innocent participants trying to get a job done, it often just blames those that are handy or unlucky. A Vice President at a large utility actually had a flow chart that fairly accurately summarized the effects of the Blame Vision (above). But the workers who drew it and sent it to him saw it as a satire on management’s performance.

The best thing about the Blame Vision is that identifying the person to blame is fairly easy. Just figure out who touched the item last. Unfortunately, when a site is caught up in the Blame Vision, there are many “mystery” incidents (when hidden problems are finally discovered). When asked what happened, employees know to act like Bart Simpson. They emphatically deny any knowledge of the problem with the following standard answer:

But management with the Blame Vision won’t let this get in their way. If you can’t find the guilty party, an acceptable solution is to arbitrarily punish a random victim. Or you can punish everyone! (That way, you are sure to get the guilty party.) We had a saying for this in the Navy:

“Why be fair when you can be arbitrary?”

A refinery manager told a story that illustrated the effect of the Blame Vision. Early in his career, he had been an engineer and was on a team that designed and started up a new process that had eventually gone on to make the company a lot of money. It had been a hard-working, close-knit team. Someone decided to organize a twenty-year reunion of all the designers, engineers, supervisors, operators, and mechanics who had worked on the project. At the reunion, everyone told stories of their part in the process start-up.

One electrician told an especially interesting story. It seems that during the first plant start-up, electricity to a vital part of the process was briefly lost. This caused a process upset that damaged equipment and cost big bucks. Valuable time was spent trying to track down the cause of the mysterious power failure. Every possible theory was tracked down. Nothing seemed to explain it. The only explanation was that the breaker had opened and then closed itself.

The retired electrician told the rest of the story to all those present at the reunion. It seems that on that day, he had been working on a problem on another part of the process. To troubleshoot the problem, he needed to open a breaker and de-energize the system. He went to the breaker box that he thought powered the system he was troubleshooting and opened what he thought was the appropriate breaker (the breakers weren’t labeled, but he thought he knew which one to open because he had wired most of the panel). That’s when everything went wrong. He could hear alarms from the control room. He thought that something he had done had caused the problem, so he quickly shut the breaker and left the area to cover up his involvement.

Later, when he was asked if he knew what could cause that breaker to open and shut on its own, he thought about telling the supervisor what had happened. But he knew that if he did, he’d probably be fired. So he said he didn’t know what would cause a breaker to open and shut on its own (technically not a lie). But, since the incident was now long past and he was retired, he thought that the statute of limitations had run out. He admitted his mistake because it was too late to punish him.

The Opportunity to Improve Vision

The refinery manager who was telling the previous story told us that if the electrician had admitted his mistake when the incident occurred, he would have been fired. Times have changed. The refinery manager wanted to make sure that when his people made mistakes, they knew they should tell the truth. The people investigating an incident could find the causes faster because the people closest to the process could actively and honestly participate in the root cause analysis and the development of the corrective actions without fear of losing their job.

His vision (and ours) is that management hires good people. If there is a problem, the people, either individually or in teams, work to solve the problem. Everyone views this as an opportunity to improve. The team doing the investigation knows better than to just address the symptoms. They are NOT looking for someone to blame. They ARE looking for the root causes. They know that if they find and fix root causes they will prevent the problem’s recurrence.

As W. Edwards Deming said:

“Management’s job is to improve the system.”

This is the Opportunity to Improve Vision. Improving the “system” is the key to improving performance.

But what is the system? The system is equipment, procedures, tools, communication techniques, training, human factors design, supervisory techniques, resources (time), policies, and rules that all impact the ability to achieve the intended goal. These are all things that management can change to improve performance.

The Opportunity to Improve Vision sees each incident as an opportunity. Not an opportunity to find a scapegoat (someone to blame). Not an opportunity to survive yet another crisis. The Opportunity to Improve Vision sees each incident as an opportunity to improve performance by changing the system.

The TapRooT® Vision & Philosophy of Improvement

In all three visions, there are problems to be solved, so what is the difference? In the Opportunity to Improve Vision, the problems are opportunities for improvement.

The book, TapRooT® Root Cause Analysis Leadership Lessons, and the TapRooT® System are for people looking for a systematic way to find effective improvement strategies – people who want to stop crisis management and blame and start sustained improvement.

The books of this series explain the lessons that leaders need to know to start a sustained improvement initiative and the tools (TapRooT® RCA) needed to systematically analyze problems and find their root causes.

The TapRooT® System was built to solve a problem and fulfill a vision. What was the problem? People at companies in a wide variety of industries were failing to improve performance. One could measure this failure by simply counting the number of times that problems were “fixed” and later reoccurred. A detailed review of 15 years of experience at one plant showed that over 90% of the problems that came to management’s attention had been preceded by similar problems during the previous six years.

This didn’t alarm management. Why? Because they had a Crisis Management Vision. Problems were problems. They had always been this way. They assumed that it always would be this way! A manager at a similar Crisis Management Vision plant said:

“If we investigated every incident we had,

we’d do nothing but investigate incidents!”

He could not see the obvious conclusion that without adequate investigations of his plant’s problems, it would be impossible to implement effective improvements. His plant would do nothing but have repeat incidents!

The TapRooT® vision was to change the way the world solves problems – change from an atmosphere of blame and fear to a new initiative of cooperative problem-solving based on finding and fixing the root causes of system problems.

To do this, we had to develop a root cause analysis system that could be effectively used by people in the field to solve both equipment and human performance problems. The system had to be easy to use and effective in helping people solve problems that they had failed to solve in the past.

This vision wasn’t easy to achieve. We started by researching human performance, researching what others who had gone before us had done, and studying the mistakes people made solving problems. We found that we couldn’t just adopt current practices. We needed to develop new strategies and techniques. The new techniques must produce repeatable results that identified fixable root causes. The system had to be robust, reliable, easy to use, and documented. It must be capable of being learned in a relatively short (no more than a couple of days) training course to help solve what seem to be simple incidents. We had to develop a new system.

We started writing the first TapRooT® Manual in 1990. It was a major leap forward, yet it was just the beginning. Our formal testing and development in the early 1990s included reviews and tests by over 300 users/reviewers who tried TapRooT® Root Cause Analysis in a wide variety of applications in a wide variety of industries. Their feedback and our use of the system in consulting led to major improvements in usability and effectiveness.

We also developed interactive training to teach TapRooT® RCA to thousands of people at hundreds of plants. What kind of people? Here are a few:

• Managers • Supervisors • Operators

• Safety Professionals • Engineers • Doctors

• Reliability Specialists • Mechanics • Nurses

• Risk Managers • Union Stewards • Operators

• Quality Improvement Specialists

Where do they work? Here are just a few of the industries:

• Refineries • Hospitals • Railroads

• Oil Drilling Rigs • Chemical Plants • Mines

• Semiconductor Plants • Rock Quarries • Pipelines

• Ships and Barges • Fertilizer Plants • Airlines

• Pulp and Paper Plants • Power Plants • Theme Parks

• Government Labs • Oil Platforms • Shipyards

• Trucking Companies • Construction Companies

• Telecommunication Facilities • Auto Manufacturing Plants

• Packaged Goods Manufacturers • Public Transit Authorities

• Government Regulatory Agencies • Nuclear Power Plants

And in what countries are these people working? All around the world. Here are just a few of the countries:

• Angola • Australia • Bahrain

• Brazil • Belgium • Canada

• China • Colombia • Ecuador

• Egypt • England • France

• Germany • Ireland • Indonesia

• Italy • Japan • Kazakhstan

• Malaysia • Mexico • Netherlands

• Nigeria • Norway • Panama

• Peru • Poland • Qatar

• Russia • Samoa • Saudi Arabia

• Scotland • Singapore • South Africa

• South Korea • Switzerland • Thailand

• Trinidad • USA • Wales

• West Indies

As you can tell, the human performance theories and equipment guidelines that form the TapRooT® System’s basis aren’t from a single industry, job description, or national culture. They work from the shop floor to the board room; from the Arctic Circle to Down Under; in a wide range of cultures and nationalities.

Why does TapRooT® Root Cause Analysis work so well in such a broad range of applications? Because people are people and machines are machines no matter where you use them. Yes, there are individual differences. Yes, some jobs require more training. But on average, people have certain human capabilities that, when exceeded, cause performance to suffer.

Human Performance

Here is an example to prove the point. One limitation is endurance (performance declining with fatigue). Everyone varies somewhat in how long they can work before requiring a break or sleep. If one works for two days without sleep, everyone would agree that at some point alertness, stupid mistakes, and ability to concentrate would change. Their overall performance would decline. That’s why a student who “pulls an all-nighter” studying for his final exam probably gets a worse grade than if he hadn’t studied at all the night before the test.

Yet the authors had an interesting conversation with a medical doctor in an emergency room. This doctor was working 36 hours on and 5 days off. The doctor, when asked how he could treat patients in a fatigued condition knowing the increased likelihood for errors, claimed that,

“I’m just as good at the end of my 36 hours as I was at the start!”

I think this proves that even people who should know better (doctors who have studied the human body) can trick themselves into believing that they can decide to overcome their own physical capabilities and limitations.

Face it. Humans can’t leap tall buildings in a single bound. They can’t run faster than a speeding bullet. Sometimes they can’t even remember a phone number long enough to dial it!

In most cases, it makes no sense to treat human error (mistakes) as if the errors were a willful act. Therefore, it makes no sense to punish a person to make them try harder and do better.

Instead, the TapRooT® philosophy is that in most industrial performance problems, we need to look at the system – the way that the work is performed – rather than criticize the individual who just happened to be doing the work when the mistake occurred.

In the fatigued doctor example, to improve performance, we need to look at the scheduling of the shiftwork that allows a doctor to work 36 continuous hours rather than the individual doctor who makes a mistake because of fatigue.

The TapRooT® philosophy is to give people a process and a systematic set of tools that lets them objectively look at the facts (what happened), identify the problems, and then find the problems’ root causes. Once the root causes have been identified, the TapRooT® Corrective Action Helper® Guide helps people think “outside the box” and create effective corrective actions that change the system to improve performance.

Therefore, we are achieving our vision for TapRooT®. By making it the best problem-solving tool and continually making the system and training better. People who learn about TapRooT® RCA are able to solve problems (improve safety, equipment reliability, quality, or productivity) that previously were blamed on people doing the work. Solving these problems improves productivity, reduces injuries, improves quality, cuts maintenance costs, and saves lives. In general, TapRooT® helps people make their company a better place to work.

Share the TapRooT® System

By sharing TapRooT® Root Cause Analysis with many companies in many industries, getting users’ comments, and continually improving TapRooT®, we are changing the way the world solves problems and working together to make our world a better place.

Maybe that sounds a little ideological, even corny, but it is our vision that is ever before us as we do our job … sharing TapRooT® RCA with companies around the world.

Many of you share this vision for a better, safer, more productive workplace for your co-workers and a better, safer, more productive world for your children. It is our hope that TapRooT® Root Cause Analysis will provide you and your company with the best root cause analysis tool available to help you and your company move further toward that vision of improved performance.

To learn more about the TapRooT® Root Cause Analysis Training, see:

And to see our upcoming public TapRooT® Training locations and dates, CLICK HERE.