What Can We Learn From a Utility Vehicle Rollover?

If you are going to operate a vehicle, a piece of heavy equipment, or even a handheld tool, ensure you understand how it will operate and what may be different from similar equipment you may have used before.

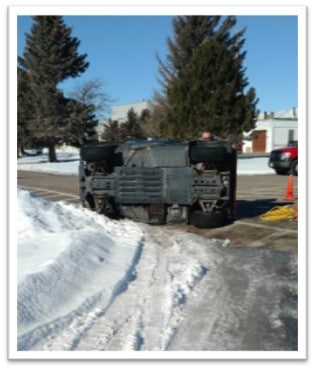

In the late morning on a January day in 2020, a two-seat utility vehicle operated by operations personnel at the Advanced Test Reactor (ATR) was on an unpaved road covered in compacted snow and ice. As the vehicle approached dry pavement, the driver decelerated to make a turn and the vehicle’s wheels braked unexpectedly, resulting in a sideways skid onto the dry pavement causing it to flip. The driver and the one passenger were not injured.

In reviewing the incident, it was identified the vehicle had a Hydrostatic drive system that included dynamic braking, so when pressure is not being applied to the gas pedal, the wheels will brake, rapidly slowing the vehicle. The road being traveled was not paved and, though it had been plowed, it was essentially compacted snow and ice. When the wheels lost traction with the ice, the vehicle went into a skid, causing it to rotate. The wheels then hit dry pavement while moving sideways and its momentum caused the utility vehicle to flip on its side.

What were the factors that figured in the incident?

Let’s look at the factors that contributed to the incident, either negatively or positively:

- The driver and passenger were wearing seatbelts.

- The driver was traveling within the complex speed limit.

- The road was used frequently and was considered part of the ATR Complex’s mapped road system. It was maintained, graded and plowed; however, not a paved road.

- The driver was not familiar with the Hydrostatic drive system of the vehicle and how it would behave on snow- and ice-covered surfaces.

Recommendations

- Do not be complacent, and always maintain a questioning attitude.

- Always use seatbelts in vehicles. Whether you are the driver, passenger, or even traveling a short distance, use seatbelts. In this incident the two occupants were buckled in and were unharmed.

- Even though the driver was not exceeding the speed limit, it is important to be aware of the surroundings and drive at a speed safe for conditions.

- When driving a vehicle on snow- and ice-covered roads equipped with a Hydrostatic drive system, keep it in 4-wheel drive so all four wheels will brake evenly when not accelerating.

This incident is shared by Department of Energy’s OPEXShare Operating Experience/Lessons Learned/Best Practices, taken from Idaho National Laboratory Operating Experience Program, INL-2020-0004, 2/27/2020.

Improve equipment reliability by using TapRooT® Root Cause Analysis

Equipment reliability professionals need great troubleshooting and root cause analysis skills. What are the biggest problems finding the root causes of equipment failures and equipment reliability issues? First, if you don’t do good troubleshooting to start with, you will lose the evidence you need to identify the failure’s root causes. That’s why we worked with equipment reliability expert Heinz Bloch to develop the Equifactor® Troubleshooting Tables. They can help your equipment experts or mechanics do a great job troubleshooting equipment problems and collecting the information you need for root cause analysis.

Second, equipment reliability experts know a lot about the equipment, but they don’t usually know about human factors. The TapRooT® Root Cause Analysis System will help guide equipment reliability experts to the root causes of equipment failures whether they are caused by mechanical failures or human errors.

Custom equipment troubleshooting tables in Equifactor®

To grow your knowledge about Equifactor® and the Equipment Troubleshooting tables, check out this great Equifactor® article by Ken Reed and view the videos listed below:

You will want to read the new Equifactor® book and then sign up for Equifactor® Training. In training, you’ll learn how to troubleshoot equipment, as well as incident investigation.

The TapRooT® Root Cause Analysis System also offers Equifactor® on-site training. Reach out via email, or call, 865.539.2139, to discuss what we can do for you. View our full selection of courses.