Voyage Planning Errors, False Alarms Lead to Grounded Ship

The use of a draft voyage planning tool which included waypoint data errors plus an ongoing technical fault with the vessel monitoring and surveillance system for the Great Barrier Reef contributed to a cargo ship being grounded on a shoal, an ATSB (Australian Transport Safety Bureau) investigation details.

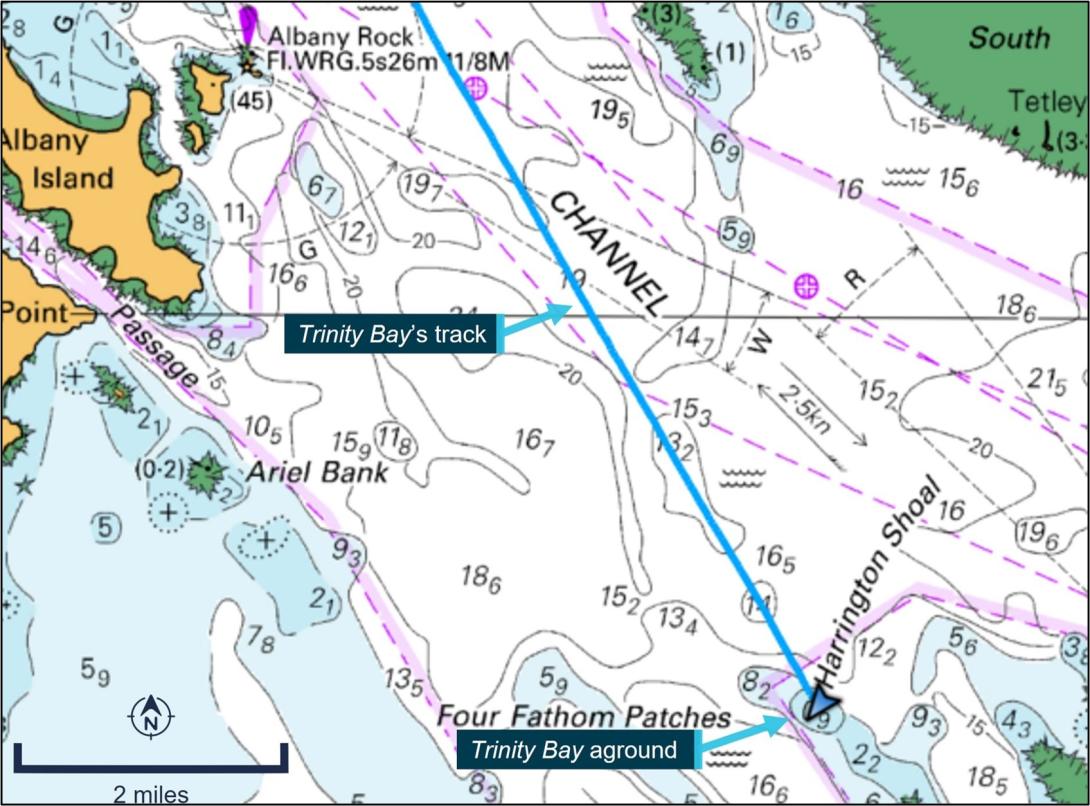

The 81-metre general cargo ship Trinity Bay grounded on Harrington Shoal, a charted feature with a depth of 0.9 metres north-west of Harrington Reef, on the morning of January 19, 2021, while conducting a regular weekly passage from Thursday Island to Cairns. Fortunately, the ship sustained only minor hull damage (some dents and paint stripping), with no injuries or pollution reported, and it was refloated on the rising tide.

The investigation report details that in an effort to address a deficiency identified during a recent internal audit, which required the use of approved routes and waypoints, the ship’s master had used a draft passage planning tool that was being trialled by the operator to plan new routes.

The planned routes from the planning tool were entered into the Trinity Bay’s electronic chart system (ECS), a navigation information system which displayed the vessel’s position and relevant nautical chart data. However, the ECS was not approved for use as the ship’s primary means of navigation and did not possess automatic route safety checking functions.

“Errors in the planning tool meant the new route took Trinity Bay dangerously close to the charted danger of Mid Rock, and then about an hour later directly over the charted danger of Harrington Shoal, where the ship grounded,” ATSB Director Transport Safety Stuart Macleod said.

“The investigation found the new passage plan was not independently verified by another of the ship’s deck watchkeeping officers, as required by the operator’s procedures, and the planned routes were entered into the electronic chart system instead of being annotated on the ship’s paper charts. In accordance with chart carriage regulations, these paper charts were the ship’s primary means of navigation, and were marked with the ship’s established previously used routes.

“Consequently, the dangers on the newly planned route were not identified, and the monitoring of the ship’s passage was ineffective in identifying these dangers.”

The ship’s operator, Sea Swift, subsequently removed Trinity Bay’s electronic chart system from service and advised the ATSB that it was investigating the fitting of electronic chart display and information systems (ECDIS) on its ships. ECDIS is an approved navigational chart and information system that can be used in place of paper charts.

“This investigation highlights how the development and use of a detailed passage plan in accordance with the accepted principles of passage planning remains essential to safe navigation,” Mr. Macleod said.

“Passage planning should be thoroughly appraised, with the route laid out and independently checked on the ship’s primary means of navigation, and then effectively monitored.”

Mr. Macleod said the ATSB’s investigation also found that at the time of the grounding an ongoing technical fault in the REEFVTS (Great Barrier Reef and Torres Strait vessel traffic service) monitoring and surveillance system, meant the duty operator at the VTS Centre in Townsville was being presented with an abnormally high number of erroneous alerts and alarms. REEFVTS monitors and communicates with ships to ensure safe and efficient navigation in Torres Strait and the inner route of the Great Barrier Reef.

Among the genuine alarms received during that time frame were warnings as Trinity Bay sailed close to Mid Rock, and again as it approached Harrington Shoal.

“Alerts associated with Trinity Bay were acknowledged by the duty operator but not followed up, due to the operator experiencing a sustained period of elevated workload, combined with a high level of expectancy that the ship was not at risk, as it frequently transited the area,” Mr. Macleod said.

“Between the duty operator commencing their shift in Townsville at 0600, and when they were alerted by the ship’s master of the grounding at 0822, that operator received over 80 alerts from the REEFVTS monitoring and surveillance system, of which at least 42 were false, generated as a result of the system fault.”

Maritime Safety Queensland, which operates REEFVTS, has since implemented a software update for the system, reducing the incidence of false alarms.

Further, the reporting area covered by REEFVTS was split into two, a north and a south area operated respectively from Townsville and Gladstone, with a separate operator responsible for each area.

Read the full ATSB report: Grounding of Trinity Bay, Harrington Shoal, Queensland on 19 January 2021.

Content/photo source/credit: ATSB, “Voyage planning errors, spurious false alarms contribute to cargo ship grounding,” published June 22, 2023.

Equifactor® Equipment Troubleshooting and TapRooT® Root Cause Analysis Training

Do you need to efficiently and effectively find the root causes of equipment failures to improve your facility’s equipment reliability? Imagine the downtime prevented, and money saved NOT having repeat equipment failures. If this sounds interesting (and worthwhile), then this completely revised TapRooT´® Equifactor® course is for you.

The Equifactor® Techniques are based on the work of noted equipment reliability expert Heinz Bloch. The tools can be used by maintenance personnel, equipment reliability specialists, maintenance managers, or investigators who don’t have an extensive understanding of equipment engineering.

Circumstances can crop up anywhere at any time if proper and safe sequence and procedures are not planned and followed. We encourage you to learn and use the TapRooT® System to find and fix problems.

TapRooT® has a team of investigators and instructors with years of extensive training ready to offer assistance worldwide. We also offer ongoing support to our clients through free newsletters and root cause tip videos, the root cause analysis blog, and our annual Global TapRooT® Summit.

Register for one of our TapRooT® courses. We offer a basic 2-day course and an advanced 5-day course.