Using Equifactor® Troubleshooting and Root Cause Analysis to Improve Equipment Reliability

Using Equifactor® Equipment Troubleshooting to Improve Equipment Reliability

What is Equifactor® Equipment Troubleshooting and how do you use it to improve equipment reliability? Before we go on, consider these questions:

- Do you have repeat equipment failures?

- Do you lack systematic methods for maintenance people to use to quickly and effectively find the causes of equipment failures so you can get the equipment back running with as little delay as possible?

- Do you waste money replacing parts only to discover that there were other reasons for equipment failures?

- Are your efforts to improve equipment performance more reactive rather than proactive?

- Would you like to cut your equipment repair bills?

- Do you have people getting ready to retire and the younger folks don’t have the same experience keeping your equipment running?

- Do you waste time troubleshooting failures only to discover that the problem was something simple that you overlooked?

If you answered yes to one or more (or all) of the questions above, you should read on to learn more about Equifactor® Equipment Troubleshooting.

What is Equifactor® Troubleshooting?

Equifactor® Equipment Troubleshooting is a systematic process for finding the reasons for equipment failures. It was developed in conjunction with equipment reliability expert Heinz Bloch. We started developing it in 1997 and have been improving the method and the training ever since.

CLICK HERE to learn more about Heinz. Heinz passed away in 2022, but his advice lives on in the Equifactor® Equipment Troubleshooting Tables.

Here is a 17-minute video that explains the Equifactor® Troubleshooting Process…

Here is the systamatic process for analyzing an equipment failure…

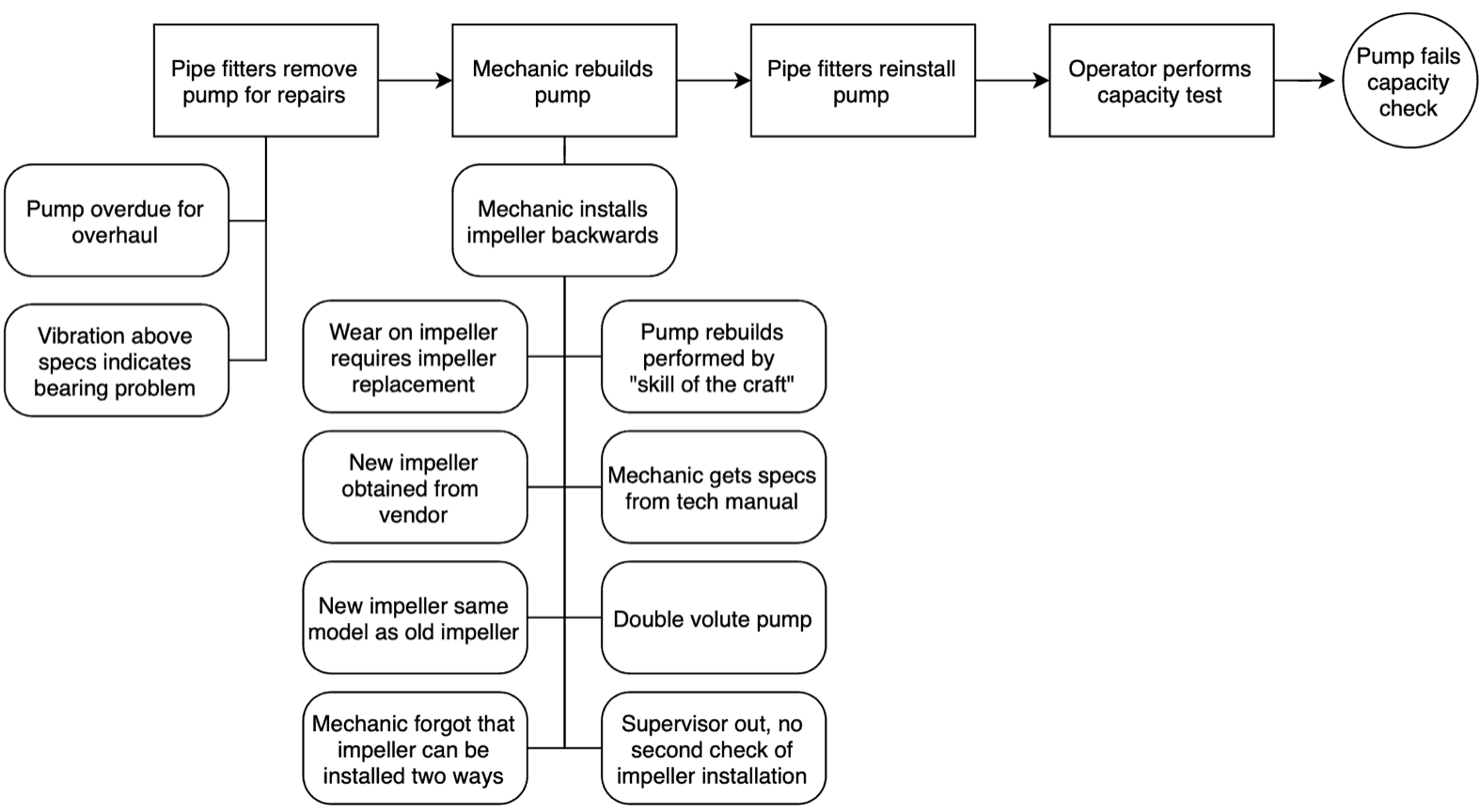

Here is a SnapCharT® Diagram for a particular failure (early in the analysis process)…

Here is the Equifactor® Trooubleshooting Table…

And here is a sample of the symptoms of a centifugal pump failure from the pump troubleshooting tables (software version)…

And here are the possible causes for a particular symptom (insufficient capacity)…

These tools provide everyone with consistent, advanced guidance when troubleshooting the failures of:

- Pumps

- Compressors

- Turbines

- Engines

- Electric Motors and Commutators

- Refrigeration

- Conveyors

- Valves

- Seals

- Gears

- Gear Couplings

- Electrical Components

Plus, you can add your own custom tables for equipment not covered by the tables above.

And for other types of failures, there are also several other techniques to help people troubleshoot the issues:

- Change Analysis

- SnapCharT® Diagram

- Failure Mode

- Failure Agent

Once the troubleshooting is complete, the next step is identifying the Causal Factors and Root Causes. This part of the system and training highlights the unique TapRooT® Root Cause Tree® Diagram that guides problem solvers to the root causes of equipment and human performance issues and the Corrective Action Helper® Guide that helps problem solvers develop effective fixes.

To learn more about the 2-Day Equifactor® Equipment Troubleshooting and Root Cause Analysis Course, including the course outline, see THIS LINK.

To see upcoming public Equifactor® Courses, CLICK HERE. Or to schedule a course at your site, CLICK HERE, or call 865-539-2139.

Troubleshooting is Just the Start

Analyzing equipment failures is just the start of how Equifactor® Training can help you improve equipment reliability. In addition to reactive analysis of failures the Equifactor® Tables can be applied proactively to:

- Proactively prevent installation errors.

- Develop preventive maintenance initiatives.

- Develop operator logkeeping schedules and rounds.

- Troubleshoot production processes

Find Out More

Equifactor® Training can help you learn to use the troubleshooting tables and TapRooT® Root Cause Analysis both reactively and proactively. See the course outline HERE.

To schedule a course at your facility, call us at 865-539-2139 or CLICK HERE.

For the dates and locations of upcoming public Equifactor® Training, CLICK HERE.