Submarine and Submersible Safeguards

Thoughts from a Submariner

For someone on a submarine or a submersible, being stuck undersea or at the bottom of the ocean is a real possibility, always in mind.

Undersea is the most unforgiving environment in which to operate, whether you’re on a submarine or a submersible. You are surrounded by a high-pressure, corrosion-inducing substance (seawater), constantly undermining the integrity of equipment and structures that are designed to keep you alive.

Submarines and submersibles are equipped with safeguards enabling those aboard to take prompt and effective action to correct a dangerous situation. When you’re deep, help is not near.

From a quick review of available information, there were safeguards and backup systems on the Titan Submersible for a loss of battery propulsion that were prudent and proper.

- Design dive depth of 4,000 meters. That’s not crush depth, that’s a design maximum. Common engineering practice is to use factors-of-safety (FOS) dependent on the environment and application. Whatever the FOS (1.2x, 1.5x, 2x, 15x), unless Titan was off course by hundreds of miles, the actual crush depth is probably something closer to 6,000 or 8,000m.

- Neutral Buoyancy at design depth: An excellent safeguard for a submersible.

- Lead ballast: A quick jostle or manual actuation, and hundreds of pounds get dropped, just like cutting off a sandbag in a hot air balloon. Quick rise! The system is designed to release ballast around 24 hours submerged to ensure automatic surfacing well before the 96-hour time frame.

- Acoustic communications: Sonar pings essentially; nothing else gets through that much water. Unless you’re talking about something like Jim Creek.

Oxygen and CO2 management are the biggest concerns in an enclosed space. Layering safeguards for defense-in-depth (I promise no pun intended) include:

- Liquid ballast: Compressed air is used to blow water out of ballast tanks. This is a mechanical system that doesn’t rely on the battery, and the air is another source of oxygen.

- Oxygen candles — yes, such a thing exists.

- CO2-absorbing fabrics.

Other safeguards to aid rescue and recovery teams include:

- SEPIRB (Submarine Emergency Position Indicating Radio Beacons) etc.

- Noisemakers: Unambiguous guides to the exact position. Install a button to reset a 30-minute timer: Don’t click the button before 30 minutes, loud noises. Separate automatic actuation at the 24-hour point in case the button fails, just like the lead ballast release.

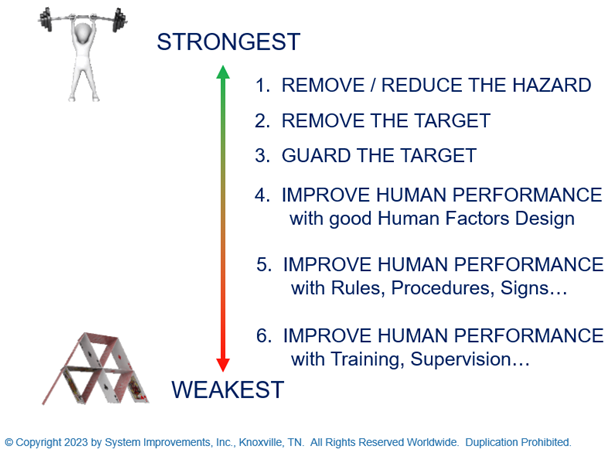

Whether you’re designing a submersible or a submarine, strong safeguards to provide defense-in-depth ensure that the dive-to-surface ratio is always 1.0. The TapRooT® Hierarchy of Safeguards is a resource to ensure that we’re not just using training, discipline, and procedures to protect our people and equipment.

Undersea operations can be conducted safely and effectively, but only if you respect what you’re doing.

“The devil is in the details, but so is salvation.”

– Admiral Hyman G. Rickover

To learn more about proper safeguard design for equipment and operations, register for the next TapRooT® Root Cause Analysis course near you!

I’ll cut loose with the final verse of “Eternal Father, Strong to Save,” also known as “The Navy Hymn.”

Lord God, our power evermore,

Whose arm doth reach the ocean floor,

Dive with our men beneath the sea,

Traverse the depths protectively.

O hear us when we pray, and keep

Them safe from peril in the deep.

Additional Information & Evaluation

Much of the controversy about the Titan submersible is about the hull design. It was made from carbon fiber with titanium end caps. Here is a CNN interview of James Cameron about the accident where he comments about the hull design…

And here is another evaluation of the hull and the accident…