Six Ways Maintenance Professionals Can Use Root Cause Analysis to Improve Equipment Performance

What Are the Six Ways to Improve Equipment Performance?

The following article explains six ways that maintenance professionals can use root cause analysis to improve performance. There are really more than six ways, but we will only cover six ways to improve performance.

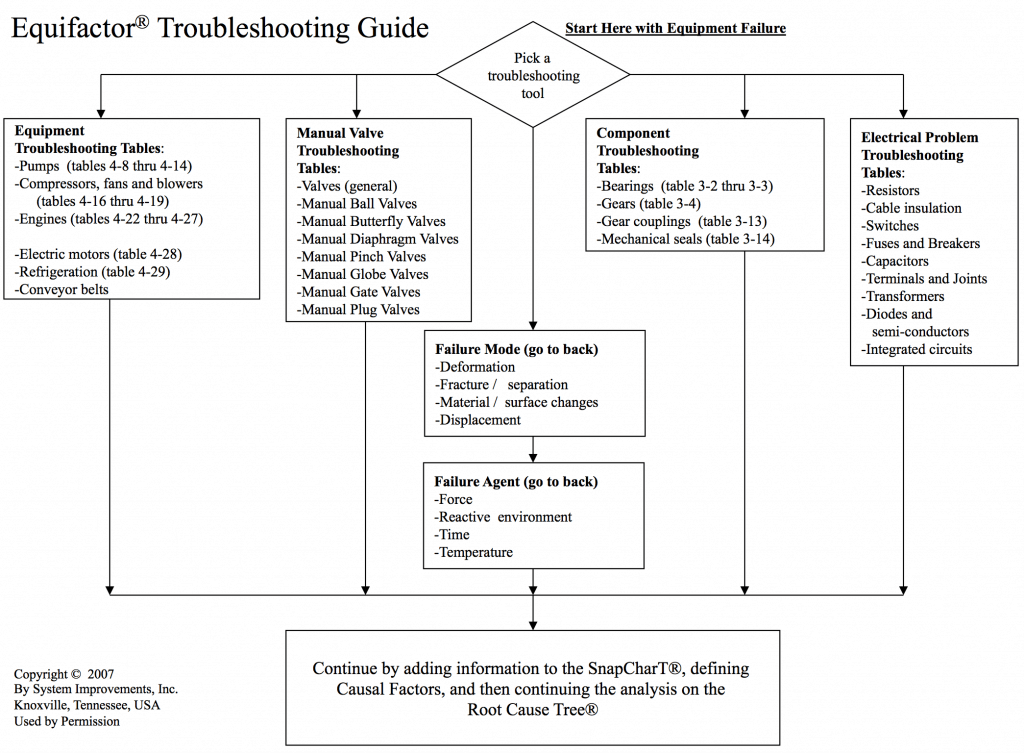

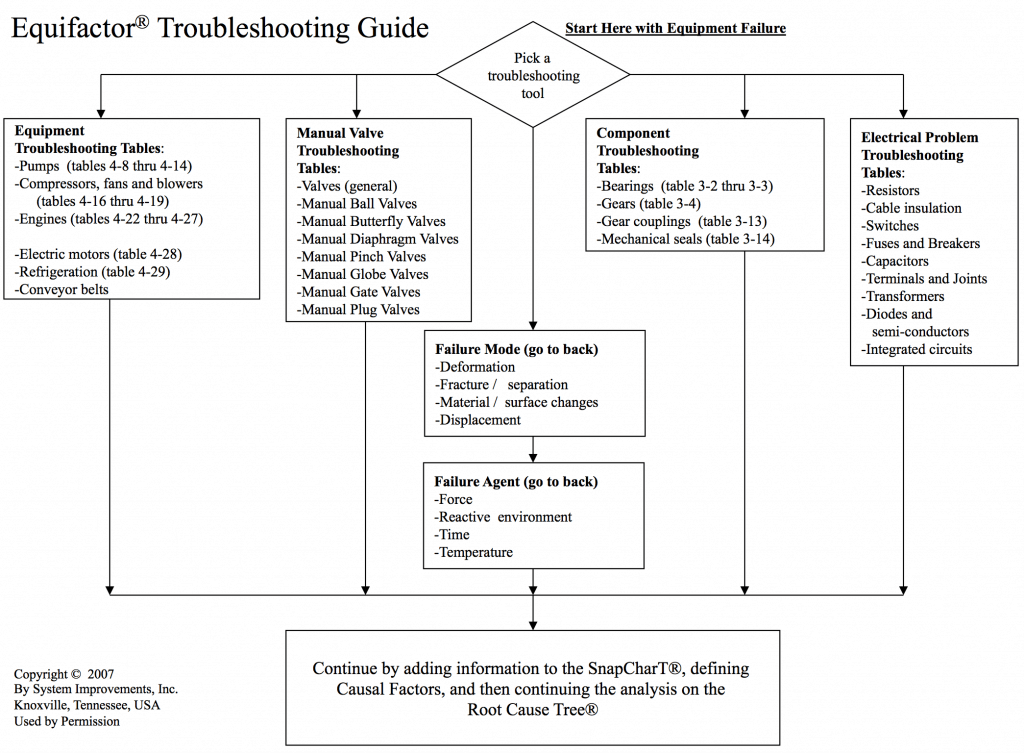

Also, you can only get all six ways if you use advanced root cause analysis – TapRooT® RCA. Why? Because TapRooT® RCA includes the advanced Equifactor® Troubleshooting Tools that are based on Heinz Bloch’s techniques that have been proven in the process industries.

So read on to find out more about how maintenance professionals can use advanced root cause analysis to:

- Stop equipment repeat failures.

- Improve uptime statistics.

- Improve equipment troubleshooting efficiency.

- Analyze the causes of maintenance-related safety incidents.

- Develop maintenance and operations practices for new equipment.

- Help operations with process troubleshooting.

Read on for details about each of the six ways that maintenance professionals can use advanced root cause analysis to improve equipment performance.

Stop Equipment Repeat Failures

This is a topic we have already written about extensively. So, I will just reference you to two previous articles and a video…

That should show you how to use Equifactor® Troubleshooting Techniques and TapRooT® Root Cause Analysis to analyze and stop repeat equipment failures by fixing the failures root causes. And it should convince you that the proprietary Equifactor®/TapRooT® Tools make this analysis and corrective action process so successful.

Improve Uptime Statistics

Improving your uptime statistics (or reduciung downtime) is a fairly simple process once you start using Equifactor® and TapRooT® to analyze and fix your equipment issues. You simply look for your biggest causes of downtime and analyze the failures that caused them using Equifactor® for troubleshooting and TapRooT® for root cause failure analysis.

You can even look at critical equipment failures proactively by using the Equifactor® Troubleshooting Tables as a way to look at what could cause equipment failures and proactively improve programs to prevent the failures with better processes, maintenance practices, operating practices, and equipment procuyrement.

Improve Equipment Troubleshooting Efficiency

One of the first surprizes we discovered when working with Heinz Bloch to develop the Equifactor® Troubleshooting Tables was that, in general, the reason that people were failing to find the root causes of equipment failures was that they weren’t doing a good job troubleshooting equipment failures.

Since they didn’t really know what caused the issue, they couldn’t identify the failure’s root causes. And therefore, their corrective actions were largely ineffective.

That troubleshooting failure made the troubleshooting efforts very inefficient. Perhaps people would guess the right answer but a large portion of the time the fixes didn’t work and problems happened over and over again.

The answer to this is to teach your field personnel to use an effective troubleshooting tool (Equifactor®). This can be done in a day in our Equifactor® Troubleshooting Course.

To see more about who needs troubleshooting training and who also needs root cause analysis training, see this article…

The results can show an amazing improvement in the efficiency and effectiveness of your troubleshooting efforts. Combined this with TapRooT® Root Cause Analysis for your more significant equipment problems, and you have a one-two punch to improve equipment performance.

Analyze the Causes of Maintenance-Related Safety Incidents

Studies and experience show that the more unscheduled, unplanned corrective maintenance (as opposed to scheduled/planned preventative maintenance) that a company performs, the higher the rate of injuries to maintenance personnel. Thus, the first way to reduce maintenance safety-related incidents is to reduce unscheduled, unplanned maintenance by improving equipment reliability (discussed above).

However, you can use the same tools (TapRooT® Root Cause Analysis) that you used to investigate the root causes of equipment failures to analyze the root causes of human errors that cause safety-related incidents (lost time injuries or fatalities).

Using the same tool for equipment failures and safety incidents is a great way to get more for your training dollar because TapRooT® is so effective for both of these types of investigation.

Develop Maintenance and Operations Practices for New Equipment

We actually mentioned this in the section on improving uptime statistics above. You simply use the Equifactor® Troubleshooting Tables to develop practices to improve equipment performance.

For example, many equipment failures are caused by improper equipment operation. Thus, if you develop effective procedures and effective training for operators, you can make a significant improvement in equipment reliability.

The Equifactor® Troubleshooting Tables can be used to discover the operating practices that could lead to failures and, thus, can provide a guide for practices to include in the procedures for equipment installation and operation and the training that is needed.

Help Operations with Process Troubleshooting

As mentioned above, many maintenance issues are caused by operating issues. Thus equipment troubleshooting problems can become process troubleshooting problems.

The computerized Equifactor® Troubleshooting Tables can be customized by adding specific tables for your unique equipment and processes. This can improve your troubleshooting effectiveness (as mentioned above) and make the best troubleshooting techniques available to all your personnel.

Below is a video of one of our Equifactor® Users, Don Brooks, explaining how this helped them improve the reliability of one of their processes with unique equipment that wasn’t originally included in the Equifactor® Troubleshooting Tables.

Learn to Use These Best Practices

Learn to use Equifactor® Troubleshooting and the TapRooT® Root Cause Analysis System in our 2-Day Equifactor® Troubleshooting and TapRooT® Root Cause Analysis Course. What’s in the course? Here’s the course outline:

Course Outline

DAY ONE

- Introductions

- Understanding What Happened – SnapCharT® Basics

- SnapCharT® Exercise

- Collecting Information

- Failure Modes and Failure Agents

- Equifactor® Troubleshooting Tables

- Human Errors

- Process Troubleshooting

- Example: Troubleshooting a Seawater Pump

DAY TWO

- TapRooT®/Equifactor® Software Introduction

- Identifying Causal Factors

- Introduction to the Root Cause Tree®

- Exercise: Walking Through the Root Cause Tree®

- Exercise: Teams Find Root Causes Using the Root Cause Tree®

- Change Analysis

- Change Analysis Exercise

- Final Exercise: Solving a Major Equipment Issue

The course materials include the book, Using Equifactor® Troubleshooting Tools and TapRooT® Root Cause Analysis to Improve Equipment Reliability, a TapRooT® Root Cause Tree®, the Root Cause Tree® Dictionary, and the Corrective Action Helper® Guide, a $129 value. The book includes a complete set of Heinz Bloch’s troubleshooting tables.

Upon completion of the course, attendees will receive a certificate of completion and a 90-day subscription to TapRooT® VI Software, our dynamic cloud-based software that computerizes the Equifactor® and TapRooT® Techniques.

We also have a 3-Day Virtual Equifactor®/TapRooT® Course that teaches the same material.

See the dates and locations of our upcoming public courses by CLICKING HERE.

Or CONTACT US to get a quote for a course at your site (or virtually).