Safety Culture: Can You Demonstrate that Your Safety Culture is Strong?

Safety Culture – What is it?

“Safety Culture” has been a topic of increasing interest since the term was first used in the report on the Chernobyl accident.

In 2004, the Institute of Nuclear Power Operations (INPO) published “Principles for a Strong Nuclear Safety Culture.” It outlines INPO’s interest and commitment to maintaining a strong safety culture in the nuclear industry.

From the INPO report, the principles for a strong nuclear safety culture are:

1. Everyone is personally responsible for nuclear safety.

2. Leaders demonstrate commitment to safety.

3. Trust permeates the organization.

4. Decision-making reflects safety first.

5. Nuclear technology is recognized as special and unique.

6. A questioning attitude is cultivated.

7. Organizational learning is embraced.

8. Nuclear safety undergoes constant examination.

These are similar to the Nuclear Regulatory Commission’s work on nuclear safety culture. See that documentation HERE. Or the pdf educational resource from the picture at the start of this article.

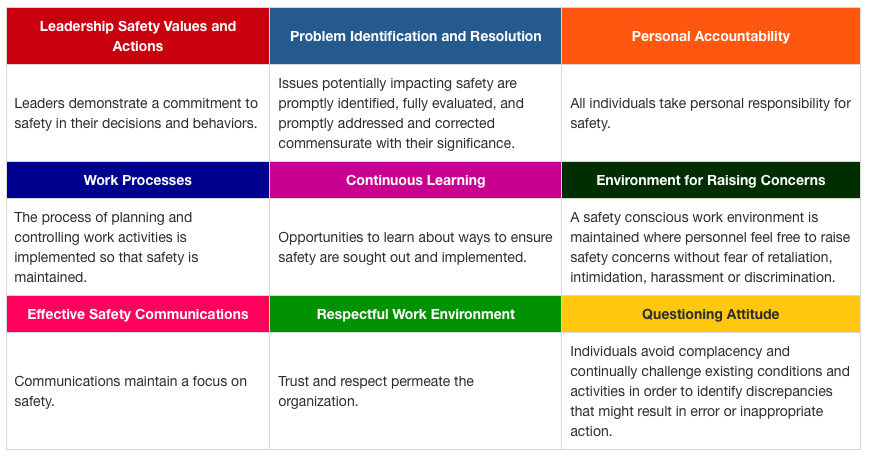

Here are the NRC’s traits of a positive safety culture…

Problem Identification and Resolution (which includes root cause analysis) is my favorite safety culture topic. The NRC’s Policy Statement says:

“Problem Identification and Resolution –

Issues potentially impacting safety are promptly identified, fully evaluated,

and promptly addressed and corrected commensurate with their significance.”

Outside the nuclear industry, safety culture has also been a topic of interest.

The Baker Panel Report on the BP Texas City explosion was critical of the BP safety culture.

How Do YOU Demonstrate a Good Safety Culture?

How do YOU demonstrate a good safety culture? For the Problem Identification and Resolution portion of the NRC’s positive safety culture, you:

- Maintain your investigation skills

- Remain knowledgeable of industry RCA standards and root cause analysis best practices

- Learn new innovative performance improvement best practices

Do you do this ONLY in your industry (Nuclear, refining, oil exploration, …), or do you look for learning across industries to find best practices?

Try This To Demonstrate Your Commitment to a Strong Safety Culture

Let me suggest a way to demonstrate your commitment to a strong Safety Culture. Attend the:

Those who have attended past Summits and one of the pre-Summit courses know that it’s a great place to maintain and advance your skills, network across industries, and learn best practices from around the world.

Therefore, attending the Summit is a great way to show that you support a strong safety culture.

Don’t contribute to a bad safety culture … REGISTER for the Summit today.