Is Human Error a Root Cause? (Updated)

Does a Human Error = a Root Cause?

A frequent question that I see in various on-line chat forums is: “Is human error a root cause?” That starts the debate. But for TapRooT® Users, the answer is obvious … NO!

Human error is probably a Causal Factor. (See the definition of a Causal Factor here). When you see human error as a root cause, the result is often to find blame and ineffective corrective action.

But the amount of discussion I see and the people who suggest corrective actions for

“human error” without further analysis is amazing. Therefore, I thought I’d provide those who are NOT TapRooT® Users with some information about how TapRooT® can be used to find and fix the root causes of human error.

Also, we now have training to help you proactively prevent human errors.

So read on to learn about:

- The definition of a root cause

- Analyzing human error using the Root Cause Tree®

- Fixing human error root causes

- A video about stopping human errors

- Learning more about stopping human errors

- Learning more about finding the root causes of human errors

And find out how you can find and fix the root causes of human errors.

Define a “Root Cause”

First, we must define a root cause. Our definition is:

“The absence of a best practice or the failure to apply

knowledge that would have prevented a problem.”

For the history of our definition of a root cause, see:

https://www.taproot.com/the-history-of-the-definition-of-a-root-cause/

But we went beyond this simple definition. We created a tool called the Root Cause Tree® to help investigators go beyond their current knowledge to discover human factors best practices/knowledge to improve human performance and stop/reduce human errors.

Analyze a Human Error Using the Root Cause Tree® Diagram

How does the Root Cause Tree® work?

First, if there is a human error, the investigator asks 15 questions to guide the investigator to the appropriate seven potential Basic Cause Categories, which allow the investigator to investigate further and find root causes.

An example of one of the 15 questions is:

The 15 questions lead you to one or more of the seven Basic Cause Categories. The seven Basic Cause Categories are:

- Procedures,

- Training,

- Quality Control,

- Communications,

- Human Engineering,

- Work Direction, and

- Management Systems.

If one of the 15 questions indicates a category, the investigator uses evidence in a process of elimination and selection guided by the questions in the Root Cause Tree® Dictionary.

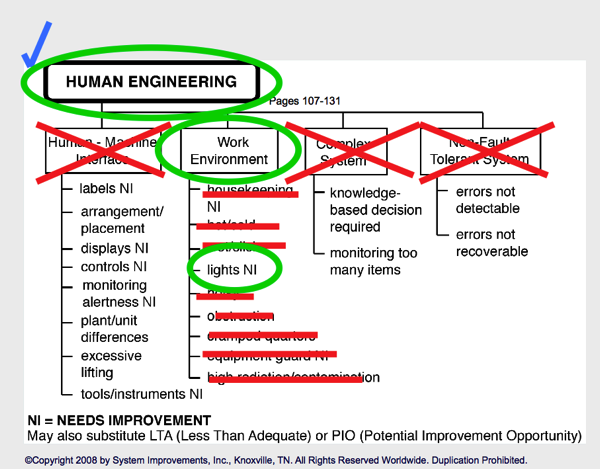

The investigator uses evidence to work their way down the tree until root causes are discovered under the indicated categories or until that category is eliminated. Here’s the Human Engineering Basic Cause Category with one root cause (Lights NI).

Users tested the process of using the Root Cause Tree® in several different industries, including a refinery, an oil exploration division of a major oil company, the Nuclear Regulatory Commission, and an airline. In each case, the tests proved that the Root Cause Tree® helped investigators find root causes that they previously would have overlooked and improved the company’s development of more effective corrective actions. You can see examples of performance improvement results by using the TapRooT® System by looking at the Solutions – By Industries tabs above (each industry has a different success story).

Fixing Human Error Root Causes

How do you fix a human error-related root cause? The answer is in the Corrective Action Helper® Guide. For each human error-related root cause on the Root Cause Tree®, Mark Paradies and a team of experts have devised the best answers for fixing that type of problem. You can get the Corrective Action Helper® Guide when you order either the book Using the Essential TapRooT® Techniques to Investigate Low-to-Medium Risk Incidents or the book Using TapRooT® Root Cause Analysis for Major Investigations or when you buy both books as a set.

What does the Guide have to say about solving lighting problems? Here are segments from the Corrective Action Helper® Module of the TapRooT® VI Software (the computerized version of the guide):

You start by checking that you are fixing an actual root cause.

Next, it provides ideas for you to consider to improve lighting.

It then provides ideas for correcting Genric Causes (problems across the facility or company).

Finally, it provides you with references to learn more about lighting.

Video About Stopping Human Errors

Now, would you like to stop human errors?

Learn More About Stopping Human Errors

There is a course that will help you proactively stop human errors:

CLICK HERE for upcoming courses.

Why should you attend the course? Ask these questions:

- Do you want to achieve excellent human performance?

- Would you like to understand the methods you can apply to effectively stop major accidents and incidents by “stopping” human error?

- Do you need to understand what are the most effective human performance improvement techniques and which ones are counterproductive (yes, some techniques really don’t work)?

- Do you want to choose the techniques that will work best for your facility?

If any of the above questions received a “Yes!” for an answer, you should attend this course.

The course will help you understand:

- The causes of human error

- Human factors design best practices

- Methods to find error likely situations

- CHAP (Critical Human Action Profile)

- Human Performance improvement Technology

- Designing your human performance improvement program for your facility.

You will leave this course with a clear understanding of methods to improve human performance and a plan to apply those methods at your company to achieve great gains in safety, quality, or operational and maintenance performance (all of which depend on human performance).

Participants will also receive the book Stopping Human Error, a $99.95 value, as part of the course materials. In addition, participants will receive a certificate of completion and a 90-day subscription to TapRooT® VI Software, our dynamic cloud-based software that computerizes the Equifactor® and TapRooT® Techniques.

Note: Sections of the Root Cause Tree® and the Corrective Action Helper® Guide above are copyrighted material and are used here by permission. Duplication is prohibited.

Any time I hear someone say that’s not the root cause, I feel they have a fundamental misconception of Root Cause Analysis. Root Causes are all the causes that allowed an event to occur.

The Root Cause is the item or items that led to all the other down the line events in the failure occurring. If not for those singular founding items, then the failure event likely never would have occurred in the first place.

Our definition is in the article above. The history of our definition is in this article: https://www.taproot.com/the-history-of-the-definition-of-a-root-cause/

FYI, the link to the causal factor definition is not working

https://www.taproot.com/root-cause-tip-whats-a-causal-factor/

Strange … it works for me. But I am the author.

It might not work for everybody else until September 18 when it is being republished (updated).

Wait and you will see it then if you can’t see it now!

Link to Cause Factor definition seems to be working now! See:

https://www.taproot.com/root-cause-tip-whats-a-causal-factor/

As mentioned on this page, human error is not a route cause, it is is symptom of bigger problems in a system.. some conditions have caused that you as a human make a error, therefore, system thinking approach is required to improve human performance , For instance , Error may caused by fatigue as result of poor shift management by organisation , then again , you need to dig more , Tap Root concentrate well on that, particular when it explain procedure issues and how contribute to incidents.. again Human element in procedure writing ..

I believe we need erase “root cause” terminology about Human Factors, because as soon as we use this term , our mind automatically directed to blaming someone, if we use “Chain causes” instead , we concentrate on conditions and other contributory factors that led an Error happen

All Asset failures come from Human mistakes during design, engineering, commissioning, operation or maintenance the asset.