How far away is death? Gas mains rock towns with fires, explosions

A late Thursday afternoon in 2018 saw thousands evacuate their homes while firefighters scrambled to respond to ten alarms and 18 fires raging simultaneously in the Merrimack Valley region of Massachusetts, due to gas mains.

Gas mains were quickly turned off to 8,000 homes, while more than 15,000 people in the Merrimack Valley were without power shortly after the explosions.

By Thursday night, the National Transportation Safety Board (NTSB) announced that it would be sending a “Go-Team” to Lawrence, Massachusetts. (The purpose of the “Go-Team” is to begin investigating a major accident at the scene as quickly as possible.) The NTSB has a special group of staff that comprise the Pipeline and Hazardous Materials Division. According to the NTSB:

“The Pipeline staff investigates accidents occurring during the transport of natural gas or other hazardous liquids, such as gasoline or propane, though pipeline systems and accidents in which public safety is threatened by the release of hazardous substances. The Division investigates all pipeline accidents in which there is a fatality, substantial property damage, or significant environmental impact.”

What Happened to the gas mains?

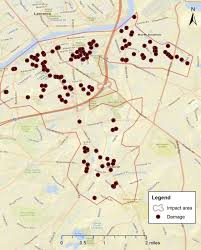

When high-pressure natural gas was released into a low-pressure gas distribution system on September 13, 2018, about 4:00 p.m. Eastern Daylight Time, a series of explosions and fires occurred in the northeast region of Massachusetts’ Merrimack Valley. (See figure below.) The distribution system was owned and operated by Columbia Gas of Massachusetts, a subsidiary of NiSource. The system over-pressure damaged 131 structures, including at least five homes, destroyed in the city of Lawrence, and the towns of Andover and North Andover.

Most of the damage was a result of structure fires ignited by gas-fueled appliances. Several structures were destroyed by natural gas explosions. One person was killed, and at least 21 individuals, including two firefighters, were transported to the hospital. Seven other firefighters suffered minor injuries.

In the aftermath of the explosions, in its subsequent and ongoing investigations, the NTSB issued a November 2018 preliminary report, stating in part the context for the incident:

“The cast-iron, low-pressure natural gas distribution system was installed in the early 1900s and had been partially improved with both steel and plastic pipe upgrades since the 1950s. The low-pressure distribution system in the affected area relied on 14 regulator stations to control natural gas at the required pressure into structures serviced by the system. Each of the regulator stations reduced the natural gas pressure from about 75-pounds per square inch, gauge (psig) to about 12 inches of water column (about 0.5 psig) for delivery to customers.¹

“Prior to the accident, Columbia Gas had an overarching plan consisting of multiple projects to replace 7,595 feet of low-pressure, existing cast-iron and plastic natural gas main with 4,845 feet of low-pressure and high-pressure plastic gas main on South Union Street and neighboring streets.

“On September 13, prior to the overpressure event, a Columbia Gas-contracted work crew, which included a Columbia Gas inspector, executed one of the Columbia Gas-designed and -approved pipe-replacement projects at the intersection of South Union Street and Salem Street in South Lawrence. The project was to install a plastic distribution main and abandon in place a cast-iron distribution main. The distribution main that was abandoned still had the regulator-sensing lines that were used to detect pressure in the distribution system and provide input to the regulators to control the system pressure. Once the contractor crews disconnected the distribution main that was being abandoned, the section containing the regulator-sensing lines began losing pressure.”

NTSB investigators learned that, until about 4 years ago, Columbia Gas required that a technician monitor any gas main revision work which required depressurizing the main. The technician—typically from the Meter and Regulation department—would use a gauge to monitor the pressure readings on the impacted main and would communicate directly with the crew making the change. If a pressure anomaly occurred, the technician could quickly act to prevent an overpressurization action. Columbia Gas offered no explanation as to why this procedure was phased out.

Although the Columbia Gas monitoring center in Columbus, Ohio, received high-pressure alarms and reported the event to the Meters and Regulations department two minutes after receiving the first alarm, there were no technicians prestaged or positioned to immediately close valves when the overpressurization occurred. Had Columbia Gas adequately performed MOC (Management of Change) and placed personnel at critical points along the system, Columbia Gas could have immediately addressed the issue and mitigated the consequences of the event. Therefore, the NTSB recommends that NiSource apply MOC processes to all changes to adequately identify system threats that could result in a common mode failure. Additionally, the NTSB recommends that NiSource develop and implement control procedures during modifications to gas mains to mitigate the risks identified during MOC operations. Gas main pressures should be continually monitored during these modifications and assets should be placed at critical locations to immediately shut down the system if abnormal operations are detected.

NTSB Recommendations

In November 2018, the NTSB issued a series of “urgent” safety recommendations. The report contained four recommendations for NiSource, the parent company of Columbia Gas, and one for the state, seeking elimination of the professional engineer licensure exemption for public utility work and a requirement for a professional engineer’s seal on public utility engineering drawings.

The NTSB report recommends NiSource do the following:

- revise the engineering plan and constructibility review process across all subsidiaries;

- review all records and documentation of natural gas systems;

- apply management of change processes to all changes to identify threats that could result in a common mode failure;

- develop and implement control procedures during gas main modifications to mitigate risks.

¹Inches of water column is a unit of pressure measurement that is typically used for low-pressure gas systems, such as a low-pressure natural gas distribution system.

Find & fix the root causes of human errors and equipment failures with the world’s leading root cause analysis system, training, and software.

Circumstances can crop up anywhere at any time if proper and safe sequence and procedures are not planned and followed. We encourage you to learn and use the TapRooT® System to find and fix problems. Attend one of our courses. We offer a basic 2-Day Course and an advanced 5-Day Course. You may also contact us about having a course at your site.