Efficient Yet Effective Root Cause Analysis

Efficient root cause analysis should be what every company and industry strives for. Of course, you need effective root cause analysis, but why waste resources on root cause analysis if you don’t need to use them there? Thus, you need efficient AND effective root cause analysis.

Of course, all right-sizing, cutbacks, and efficiency initiatives have a dark side … striving too much for efficiency can lead to too little emphasis on quality. Thus, companies need to ensure they don’t devote too few resources to root cause analysis of problems. If companies invest too little in root cause analysis, they will end up using even more resources by:

– Having recurring incidents and repeating investigations that weren’t done correctly in the first place,

– Wasting effort on corrective actions that only address the symptoms and not the real root causes,

– Wasting management effort reviewing investigations and root cause analysis that isn’t as good as it should be (and therefore gets rejected by management)

– Being cited by a regulator for poor investigations and inadequate root cause analysis

– Having a major fine or your facility shut down over a regulatory issue that could have been corrected earlier by good root cause analysis

– Having a major accident that could have been prevented by good root cause analysis of the prior incidents that were warning you about a problem (If only you had listened more effectively!).

So devoting enough resources to root cause analysis without going overboard is the key to an effective, efficient performance improvement program that you can continually apply and which will produce a healthy return on the effort and $$$ invested.

So, what are the keys to efficient yet effective root cause analysis? Read on and see…

When I think of efficient, effective investigations, I think of using TapRooT® RCA.

TapRooT® Root Cause Analysis was designed and has been improved over the years to provide a tool that produces effective root cause analysis and investigation EFFICIENTLY. But to be efficient and effective, you need to use TapRooT® RCA the right way.

What is the right way to use TapRooT® RCA efficiently and effectively? Here are my TOP 10 suggestions for using TapRooT® RCA efficiently yet effectively:

1. Sufficient training and practice for the investigation facilitator (team leader) and the investigations team.

2. Assigning enough, but not too many, people to the investigation team.

3. Use investigation team efficiency strategies.

4. Get inside/outside help when needed.

5. Be prepared for an investigation BEFORE the incident/accident happens.

6. Don’t waste time investigating small problems that don’t deserve to be investigated. Instead, use trending to spot developing problems from small issues and then apply root cause analysis.

7. Keep up-to-date on current investigation best practices.

8. Use your TapRooT® Tools effectively to improve efficiency.

9. Get employees (not just team members) trained in the basics.

10. Get management trained.

Let me share a few more ideas about each idea so that you can apply these ideas and get the most return on investment possible from your investigations and root cause analysis.

1. Training and practice for the investigation facilitator (team leader) and the investigations team.

Let’s talk about training first. Any professional knows that over-training and practice helps a team perform well when the pressure is on. Professionals at all levels (from the military to professional sports to highly educated

The more serious the accident, the more the investigation team will be under pressure. Thus the more training and practice they will need to ensure good performance.

But even (or especially) for minor incidents, an untrained or poorly trained team can waste considerable resources and make root cause analysis look like a waste of time.

Therefore, you must start thinking about OVER training your team leaders and team members.

So let’s start out with the recommended training. Then we can review OVER training.

For more about TapRooT® Training, CLICK HERE.

Once your teams and team leaders are trained, investigators will need to gain experience and get feedback to become efficient.

Think of the recommended training as the minimum octane that will make your car “work.” It will run, but it will sputter, backfire, knock, and be very inefficient under heavy loads.

But training isn’t all that is needed. To keep their skills sharp, investigators and team members need practice and feedback.

They should perform no less than one investigation per month.

They should get feedback on this investigation (both positive and negative feedback) from the sites EXPERTS in root cause analysis – a peer review committee of three or four of the best investigators.

The feedback should be aimed at:

- Completeness of the investigation and consistency of use of the TapRooT(R) Tools (complete, accurate SnapCharT® with all assumptions resolved, all Causal Factors defined at the proper level, and proper use of the Root Cause Tree(R) – especially the Management Systems section)

- Completeness and effectiveness of the proposed corrective actions (SMARTER and evaluate using Corrective Action Helper® Guide)

- Effectiveness of presentation

Now for OVER-TRAINING.

What should you do to overtrain your best investigators, team leaders, and team members? Here are some ideas:

a) For a fairly large site or a corporate office, you should have several “key investigators” who serve on the peer review committee (mentioned above). Over-Training for them should include:

- Attending the Global TapRooT® Summit every year.

- Attending advanced root cause analysis, incident investigation, human performance, and equipment troubleshooting training every year. These could include courses given before the Global TapRooT® Summit, like the Stopping Human Error Course, the Coaching Skills Course, the How To Interview and Gather Information Course, the Creative Solutions Course, the Advanced Trending Techniques Course, or the Equifactor® Course.

- Providing a presentation to investigation team members at their site and management about the lessons learned from the Summit and the advanced training they attended.

- Read each issue of the Root Cause Network™ Newsletter.

- Serve on the TapRooT® Advisory Board

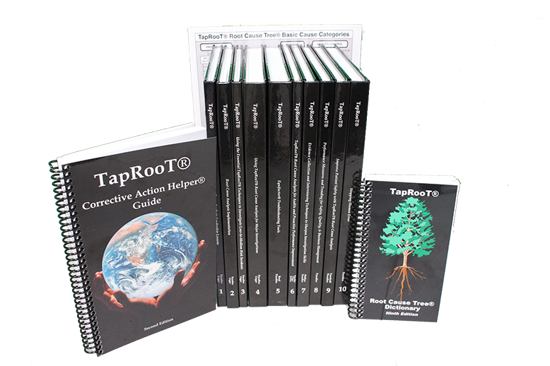

- Read all ten TapRooT® Books.

b) All Team Leaders should:

- Attend the TapRooT® Summit at least every two years.

- Attend advanced root cause analysis training at least every two years.

- Provide a presentation to investigation team members at their site and management about the lessons learned from the Summit and the advanced training that they attended.

- Read each issue of the Root Cause Network™ Newsletter.

- Read TapRooT® Books 3 and 4.

- Attend the presentation by the key investigator about the Summit and the advanced training.

c) All trained team members should:

- Attend refresher training at least once every two years.

- Attend the 5-Day Course if they plan to progress to be a Team Leader.

- Read each issue of the Root Cause Network™ Newsletter.

- Read TapRooT® Books 3 and 4.

- Attend the presentation by the key investigator about the Summit and the advanced training.

2. Assigning enough people to the investigation team, but not too many.

How many people should be on an investigation team? If you can’t count them on one hand, you probably have too many.

For really big investigations, you may decide to have a core team (maximum 10) and sub-teams for specific purposes (for example, analyzing the failure of a particular piece of equipment). These sub-teams can be thought of as an investigation within an investigation.

For smaller incidents, you should have a “team” of only one or two investigators. YES – one investigator can be the “team.”

If your teams get too big, the team will waste tremendous amounts of time keeping everyone informed and reaching a consensus. This wasted time does not contribute to the quality of the investigation.

Don’t forget, you can have technical experts who contribute but who aren’t part of the team.

Now, who should be ON THE TEAM?

1. A Team Leader

2. Someone technically familiar with the process/work (but probably not someone who participated in the event)

3. Someone with influence/authority in the organization who will most likely have to make changes as a result of the investigation.

Note that one person could meet all three of these criteria.

Note also that every organization and every technical discipline at your company needs someone trained as a team member.

Final comment: Keeping your teams to five people or less will dramatically increase the efficiency of your investigations. Going beyond five people starts an exponential increase in team coordination.

3. Use practices to keep the team efficient.

Team Leaders need to think about efficiency during investigations. They can use practices that will help their team be efficient.

What tools keep a team efficient? Try these.

a) Use the Spring SnapCharT® Diagram to plan the investigation. Planning reduces needless effort.

b) Think about interviews and schedule them to efficiently collect information and to minimize interviewers’ and interviewees’ time.

c) Use no more than two investigators in an interview.

d) Don’t waste time doing things in team meetings that could be done by one individual outside the team meeting (for example, redrawing a SnapCharT® Diagram).

e) If analyses or information are delayed or won’t be available for a period of time, Call a temporary halt to the investigation and let people get back to their normal jobs.

f) Keep an investigation “to-do” list and a meeting “to-do” list to keep the investigation and meeting on track.

g) Let the investigation team know that you, the team leader, and management are interested in investigation efficiency and effectiveness. Then, track the hours spent and find out why things are taking longer than planned.

h) Make sure that there is sufficient management support for an investigation. Investigators cooling their heels waiting for people to interview, fighting with contracts over support purchase orders, or the inability to get a meeting room to use as the “war room” for the investigation team should not occur or should be “solved” by management support. The main challenge in getting an investigation done should not be overcoming bureaucratic obstacles. If these obstacles are slowing down investigations, get them solved once and for all.

i) Provide administrative assistance for the team. The appropriate staff should handle copying and other administrative tasks.

4. Get inside/outside help when needed.

An investigation team needs to know when to get help, and their should be pre-planned assistance available for:

- metallurgical analysis

- oil analysis

- human factors analysis

- outside expert facilitators

- accident reconstructionists

- technical experts on equipment

- computer experts

Once upon a time, companies had their own internal experts. Now, most of this expertise has been downsized. Make sure that you have planned to get this expertise when you need it. (Contracts already in place before an accident even happens.)

5. Be prepared for an investigation BEFORE the incident or accident happens.

Have you prepared for investigations? Read Appendix A of your TapRooT® Book 2 and then get things prepared.

6. Don’t waste time investigating small problems that don’t deserve to be investigated. Instead, use trending to spot developing problems from small issues and then apply root cause analysis.

You need to clearly distinguish between what needs investigating and what does not. Things that get investigated should show a clear return on investment for the investigation.

Smaller problems should be trended.

Remember to ask the question:

“DOES THIS INCIDENT REALLY NEED INVESTIGATING?”

To answer this question, consider:

a. Are the consequences serious enough to be worth the effort of the investigation investment?

b. What will the return be on my investment in investigation time and effort?

c. Is this a failure that could lead to more serious failures, or are the consequences of this failure minor at best?

d. Is this a repeat failure that happens so frequently that stopping multiple repeat failures is worth the investigative effort?

e. Is this some management, regulatory, or public relations “hot button” that may be worth investigating for political reasons?

If the incident is not worth investigating, you should record the event in a database so that you can track the failure type and location. Future data may show an increasing trend of failures or an unacceptable rate of repeat failures.

Some may see this lack of small investigations as a problem. After all, if investigating big problems and performing root cause analysis is a good thing, why not do more for smaller and smaller problems?

First, most small investigations are done halfheartedly. That makes for poor investigations. And since the problem is small, they don’t get a peer review and get little management review. because of a lack of effort, the real causes are not discovered and the corrective actions are a waste of time and effort.

Second, no matter what your philosophy is about small investigations, eventually, everyone must agree that everything can’t be investigated. So management needs to provide direction and guidance for the appropriate cut off for root cause analysis. So consider developing clear guidance. For example:

a. Serious Accident: The level of damage or loss caused by the accident means that this investigation will probably get regulatory, senior management, shareholders, and potentially public attention. The extreme consequences mean that this will also be the most difficult type of investigation. This type of investigation will take a dedicated team of highly trained company investigators and consultants to conduct a thorough review of all evidence. The complete suite of TapRooT(R) Techniques will be employed. A considerable investment in time and resources will be required, as well as a senior management review of the investigation results and potentially an independent review by a highly experienced outside reviewer. This is obviously NOT the type of investigation imagined by this question.

b. Serious Incident: The level of damage or loss caused by this incident is worthy of investigation and root cause analysis. This incident is serious because it caused damage just below what is required to trigger a “Serious Accident” investigation or because it could have easily caused a Serious Accident with slightly different circumstances or without the intervention of luck. This investigation will be similar to the investigation above with the exception that some of the team members may be slightly less experienced, fewer consultants will be used, and the review of the investigation will be by local management, and an investigation peer review committee made up of local investigation experts. Once again, this investigation is above the “minor” investigation posed by the user’s question.

c. Incident: This incident caused minor damage or loss and there was at least one significant safeguard (which was NOT luck) to keep the incident from becoming a Serious Incident. In this case, a single investigator or a small investigative team may be used to perform the investigation and only two tools will be used to perform the investigation: SnapCharT® Diagram and the Root Cause Tree® Diagram). These types of incident investigations will receive a brief review by the peer review committee but will not receive a management review unless a trend is detected.

d. Recordable Event: These events are judged not to be worthy of investigation. The type of event, organization, and location are recorded in a database to allow trending. Since no investigation is performed, no corrective actions are recommended, and future recurrence of the event is possible. Trends will be used to detect the significantly increasing frequency of these events.

Here is a tip for the nuclear industry: All “significant conditions adverse to quality” should be rated as an incident or above and, therefore, deserve root cause analysis. If it is not a significant condition adverse to quality and it is not in another category that makes it significant (cost, delayed startup, personnel injury, non-nuclear environmental release, …), then a nuclear facility should categorize the problem and NOT waste time doing some sort of halfhearted “Apparent Cause” evaluation that will waste time and corrective action effort implementing fixes that aren’t effective.

7. Keep up-to-date on current investigation best practices.

Every year, the TapRooT® Summit presents new good practices for investigating. These have included ways to improve investigation efficiency and effectiveness. Recently, the Summit has a whole track devoted to investigation best practices. Examples from the Summit planned for April of 2006 include:

– Establishing a just culture/no blame environment

– Investigation/corrective action best practices session

– Best practices for managing investigations with potential for litigation

– Ranking the risks of your incidents

– Ranking the importance of your corrective actions

– Evaluating the effectiveness of your investigations

– TapRooT® User best practices

– Best practices for fast analysis of small problems

If you implement best practices for your investigations each year, you will have an industry-leading investigation program that is efficient and effective!

8. Use your TapRooT® Tools effectively to improve efficiency.

The TapRooT® System was designed to promote effective, efficient investigations. The TapRooT® Software was designed to make the TapRooT® System even more efficient.

How?

First, the software supports the investigator by providing an easy-to-use tool for drawing presentation quality SnapCharT® Diagrams.

Second, the software makes access to the Root Cause Tree® Dictionary a snap (just one click away).

Third, the results of your investigation are recorded while the analysis is performed. No need to enter data separately.

Fourth, the Corrective Action Helper® Module provides great ideas for developing corrective actions. This adds greatly to the efficiency and effectiveness of the corrective action process.

Fifth, the Equifactor® Troubleshooting Tables can help investigators develop troubleshooting plans so that key equipment failure evidence is not lost and troubleshooting is done in the most efficient/effective manner.

9. Train employees (not just team members) in the basics.

If employees know a little about root cause analysis, you will be surprised how much more helpful they can be to the investigation team. They can:

– save key evidence,

– provide better information during interviews

– suggest paths to help the investigation progress,

– support the investigation recommendations

10. Get management trained.

There is nothing worse than performing a difficult investigation and then having management fail to understand the lessons learned because they don’t understand root cause analysis and performance improvement methods.

The ultimate in inefficiency is having to rewrite and investigation report and add ineffective, or worse yet – counterproductive, corrective actions dictated by management.

Have you seen management mandate punishment when it wasn’t called for by the investigation?

Have you seen management insist that more smaller problems be investigated even though they didn’t meet the investigation criteria?

Have you seen management insist there is a bad trend when there is way to little adata to detect a trend?

have you seen management spend millions of dollars fixing problems that don’t exist?

Root cause analysis and performance improvement training for management is probably one of the best investments in time and $$$ that a company can make.

This training should be customized to meet the company’s most pressing challenges.

ONE FINAL IDEA – Proactive improvement is much more efficient than reactive improvement…

If targeted correctly, use of the TapRooT® Tools for proactive improvement is the most effective/efficient improvement strategies that a company can adopt. If you are truly interested in the efficiency of improvement, consider becoming more proactive with your use of TapRooT® RCA. (See TapRooT® Book 6 for more ideas.)