Learn to be an Effective Problem-Solver

Why do we recommend spending time investigating low consequence incidents? Because under different circumstances or with one or two more failed Safeguards, a low consequence incident could be a big problem. The TapRooT® System is built around this philosophy. Companies should learn from small problems (we call them “precursor incidents“). Thus, we developed three main courses to train your problem-solvers.

Become a TapRooT® Root Cause Analysis Investigator in Just 2 or 3 Days

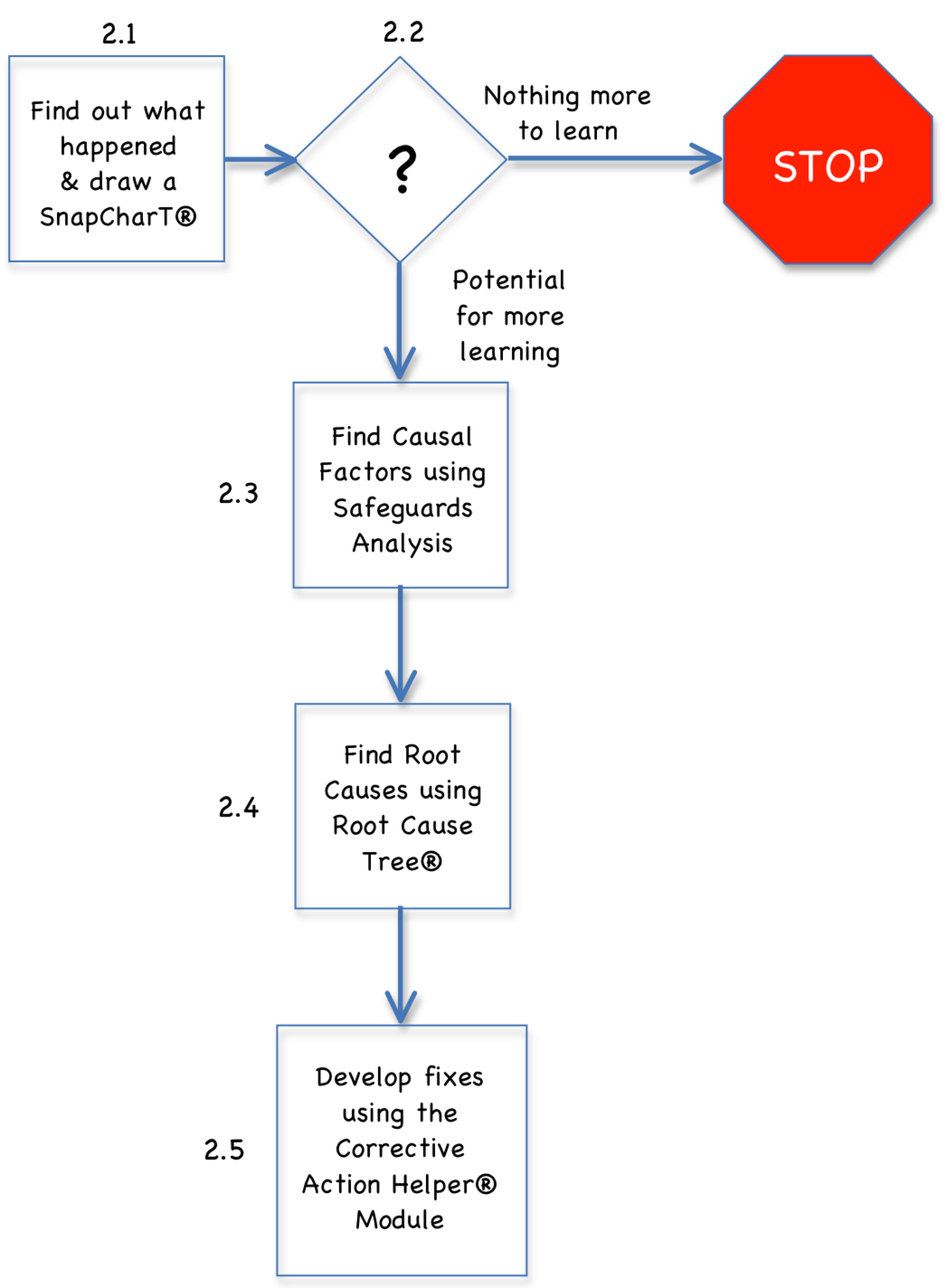

Attend 2-Day TapRooT® Root Cause Analysis Training. This course teaches the essential TapRooT® Techniques used in the 5-Step TapRooT® Process for investigating and fixing precursor incidents. It’s designed to get people started quickly doing what they will do the most – investigate low consequence incidents that could have been worse.

Do you prefer to attend virtual training? Our Virtual 3-Day TapRooT® Root Cause Analysis Training takes the 2-Day TapRooT® Training and makes it an interactive, live, virtual course for those that can’t attend the in-person training.

Become a TapRooT® Root Cause Analysis Team Leader in Just 5 Days

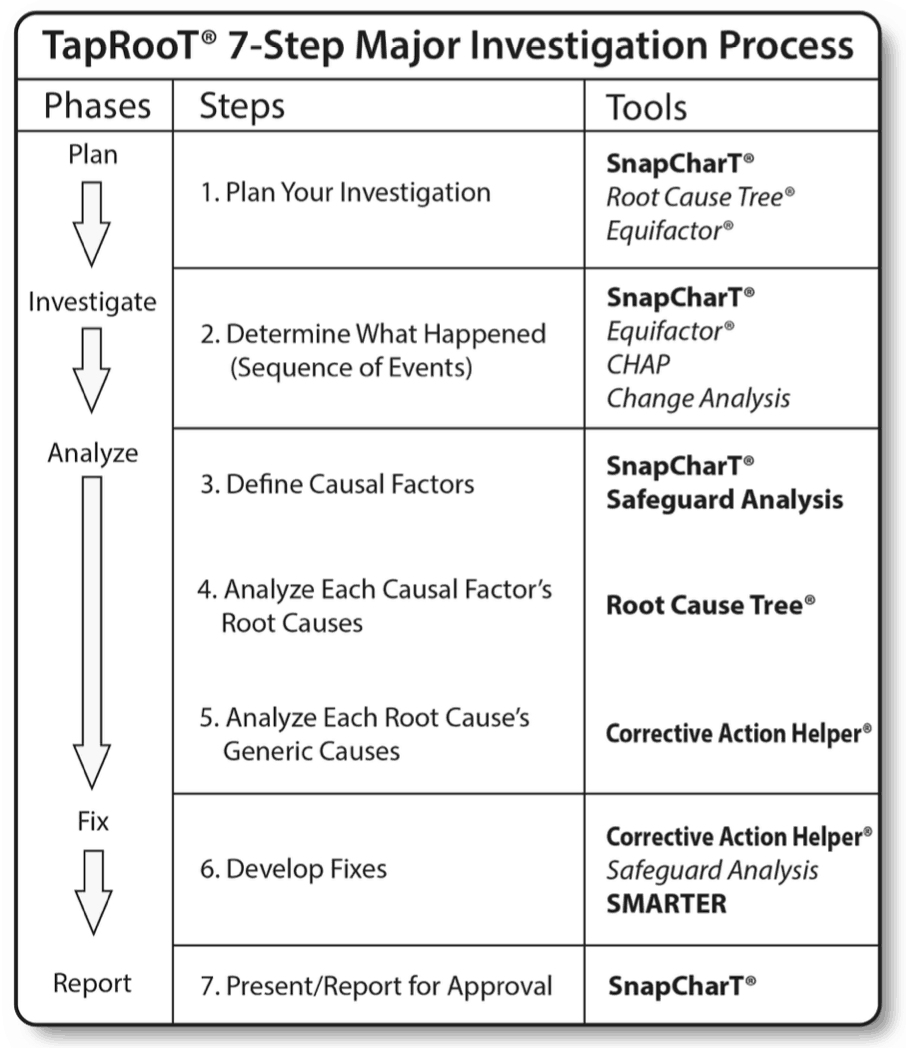

The 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Training is for your experts who perform investigations of precursor incidents, coach others who investigate precursor incidents, and lead the investigation of complex accidents. This training provides the attendee with advanced tools such as the TapRooT® 12-Step Interview Process, Critical Human Action Profile (a form of task analysis for better information collection), Change Analysis, proactive use of TapRooT® Root Cause Analysis and a deep dive of the Basic Cause Categories on the TapRooT® Root Cause Tree.

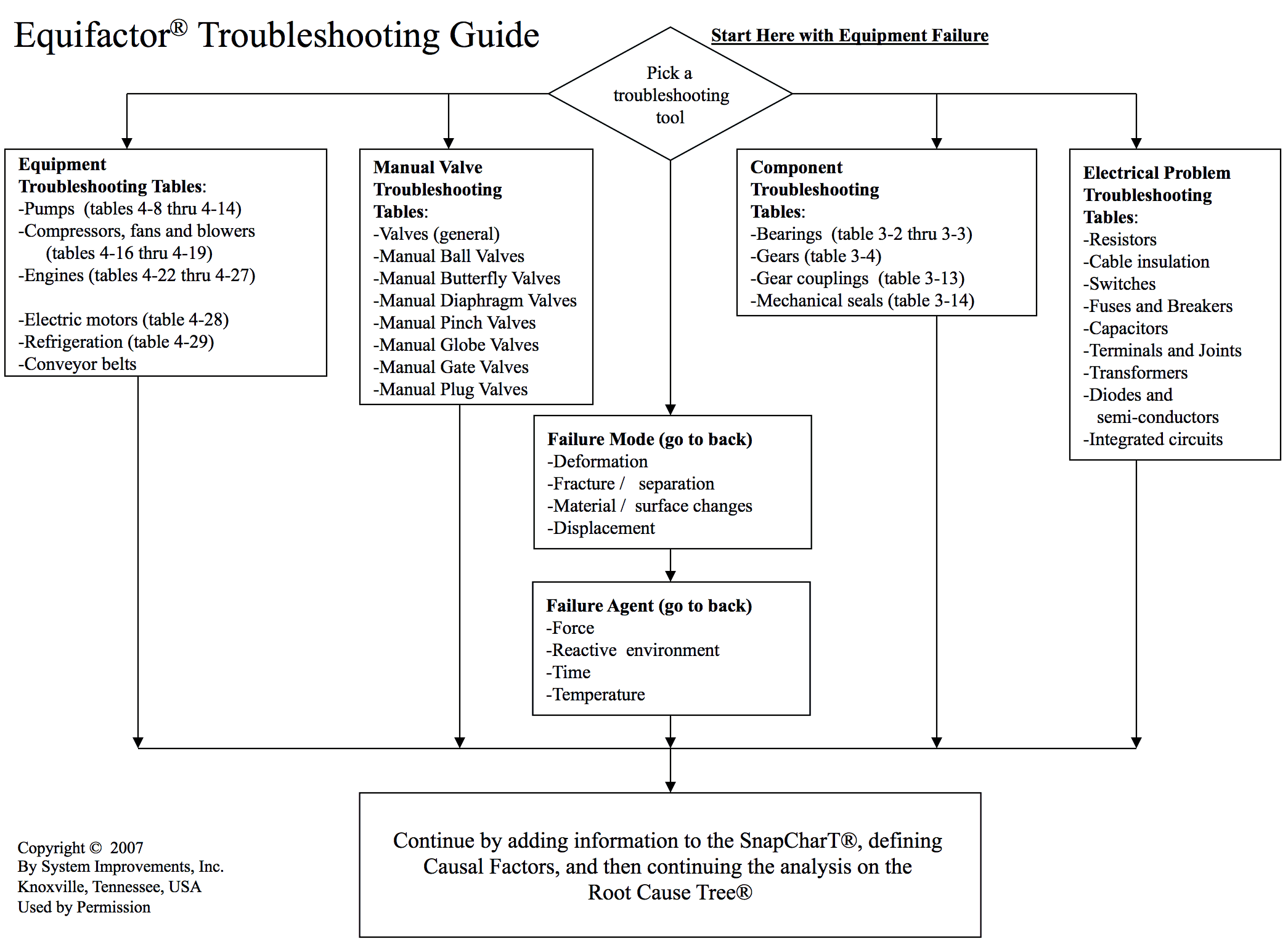

Troubleshoot Equipment Problems like an Expert in Just 2 Days

The Equifactor® Equipment Troubleshooting and TapRooT® Root Cause Analysis Training is designed for those interested in equipment reliability and maintenance. Learn Heinz Bloch’s troubleshooting techniques to completely understand an equipment failure and the TapRooT® Root Cause Analysis System to go from what happened to cause the failure to what you can do to prevent repeat failures in the future.

Of course, we also have other specialty courses that we will explain below.

All of our Root Cause Analysis Training Comes with a Money-Back Guarantee

Attend the TapRooT® Training. Go back to work and use what you have learned to analyze accidents, precursor incidents, quality problems, or equipment failures. If you don’t find root causes that you previously would have overlooked and you AND your management team don’t agree that the corrective actions that you recommend are significantly more effective, just return your course materials and we will refund the entire course fee. No questions asked – no hard feelings – it’s that simple.

How can we offer such an iron-clad guarantee? Because we know that TapRooT® will help you solve problems!