Runaway & Derailment of TasRail Freight Train in Devonport, Tasmania

At the time of the runaway, TasRail was using the third generation of RCE developed and manufactured by Air Digital Engineering (ADE) to remotely operate the cement train.

On the morning of September 21, 2018, a train driver was using remote control equipment (RCE) to control and position TasRail train no. 604 so that it could be loaded with cement powder at a siding in Railton, Tasmania. The driver was outside the train and no one else was on board.

Having overshot the intended location to load the last two wagons, the driver attempted to use the RCE transmitter to reverse the train. However, the train did not respond to their commands. The driver attempted procedures to recover the RCE from known failure modes in order to restore control, however, these were unsuccessful.

As the driver began to walk toward the locomotive to attempt to reset equipment, they noticed the train starting to move. They attempted several methods to command the train to stop by using the RCE transmitter, but these were unsuccessful. Instead, the train, which was on a downhill grade, continued to roll away, leaving the siding and entering the main line toward Devonport.

The driver notified TasRail network control of the runaway, and they in turn notified emergency services.

Network control also organized for the points at the entrance to Devonport Yard to be set to divert the train from the main line, which continued past this location into a dead-end siding within the yard.

The train traveled through ten active and three passive public level crossings, beneath a highway overpass, and through five sets of points, mostly at speeds greater than the maximum track speed. It reached a maximum recorded speed of 87.5 km/h.

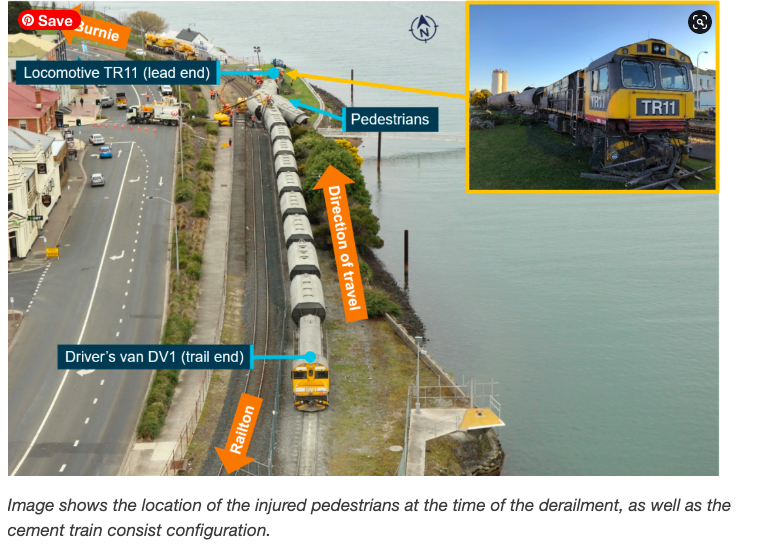

About 23 minutes after the train rolled away from Railton, it collided with a concrete footing and surrounding fences at the end of the silo siding in Devonport Yard. The derailment caused significant damage to the train’s locomotive and seven wagons, as well as damage to the end of the siding and fences. Fence debris struck two pedestrians who had been walking in the area, resulting in minor injuries to both.

Read here to learn what the ATSB found in its investigation, what has been done as a result, and the safety message.

Source for content and image credit: ATSB (Australian Transport Safety Bureau), “Runaway and derailment of TasRail freight train in Devonport, Tasmania on 21 September 2018.“

Founded in 1988, the TapRooT® Root Cause Analysis System solves hurdles every investigator faces.

TapRooT® Root Cause Analysis Training System takes an investigator beyond his or her knowledge to think outside the box. Backed with extensive research in human performance, incident investigation, and root cause analysis, TapRooT® is a global leader in improved investigation effectiveness and productivity, stopping finger-pointing and blame, improving equipment reliability, and fixing operating problems.

System Improvements, the creator of the TapRooT® System, has a team of investigators and instructors with years of extensive training ready to offer assistance worldwide. We also offer ongoing support to our clients through free newsletters and root cause tip videos, the root cause analysis blog, and our annual Global TapRooT® Summit.

When you can’t afford to be in the headlines

Prevent blowouts, fatalities, injuries, spills, and cost-overruns by using TapRooT® Root Cause Analysis to find and fix the root cause of problems.

Why does one of the biggest oil companies in the world require all of their contractors to use TapRooT® Root Cause Analysis? Because they need excellent performance and no accidents. They want everyone—employees and contractors—to have a safe day. And, they know that TapRooT® will help them find and fix the root causes of problems to achieve excellent performance.

Register for a TapRooT® Root Cause Analysis Training Course

Register for one of our TapRooT® courses. We offer a 2-Day TapRooT® Root Cause Analysis Course and a 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Course. Contact us or call us at 865.539.2139 about having a course at your site or for further root cause analysis training opportunities. We’re here to help you find solutions.