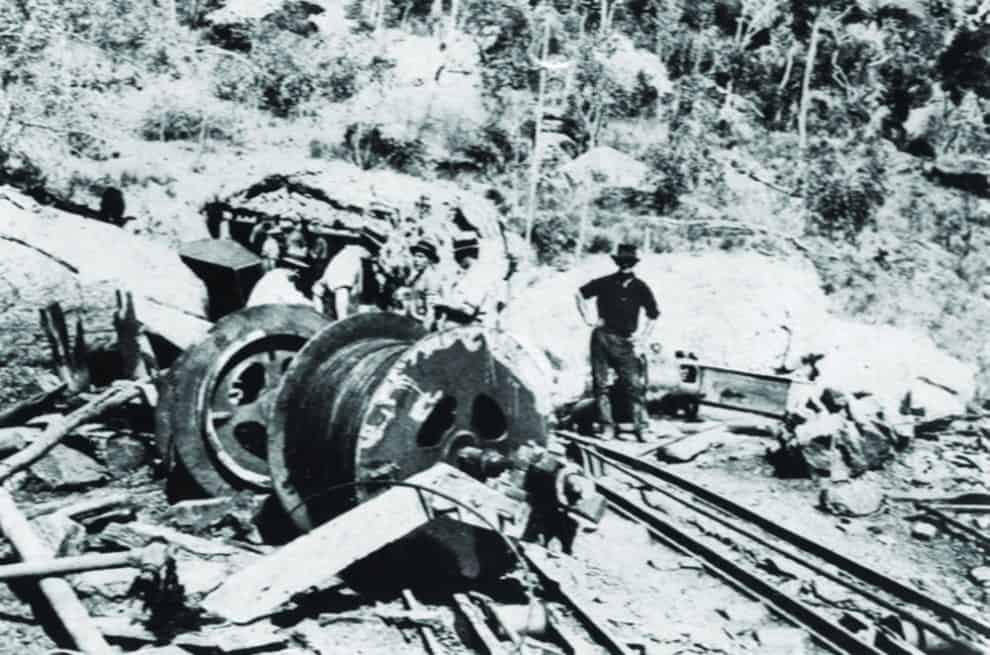

Remembering an Accident: What Caused the Mount Mulligan Mine Disaster 104 Years Ago?

The Mount Mulligan Mine Disaster was Queensland’s worst mining accident.

The morning of September 19, 1921, a series of explosions in the local coal mine rocked the town in Far North Queensland, Australia—explosions so powerful that they killed four people who had merely been standing at the mouth of the pit at the time—the Mount Mulligan mine had exploded.

Witnesses who rushed to the mine upon hearing the explosion reported heavy black smoke billowing from the mine’s entrance and the surrounding grass smoldering from the force of the explosion. Large pieces of debris were strewn up to 40 meters away. It was immediately apparent to all that the chances of anyone surviving underground after an explosion of that magnitude were slim.

The Mount Mulligan mine had been open for six years before the series of horrifying explosions ripped through the coal mine that morning. The explosion could be heard 30 kilometers away and devastated the people of the fledgling Mount Mulligan township.

The disaster claimed 75 miners in the third-worst coal mining accident in Australia

Mine safety professionals across the country were forced to reassess their attitude toward handling explosives in so-called “gasless” mines after the 1921 Mount Mulligan mine disaster. The disaster was also the impetus for the passing of a Coal Miners Act in Queensland that would ban the use of open flames in underground coal mines.

“ . . . going into the mine after the explosion was one of the bravest things imaginable, and it was remarkable that more men were not lost in the rescue work.”

Edgar Smith, Government Geologist

The accident was particularly shocking as the mine was widely considered safe and had no previous indications of gas leaks. The assumption that the mine had a low gas risk would prove to be the undoing of the 75 unfortunate miners; they worked under the flickering light of an open flame instead of the electric safety lamps that were available at the time.

The Mount Mulligan Royal Commission found that the explosions were triggered by detonation of flammable gas

In its findings handed down, the Commission found “The cause of the ignition was the firing of an explosive, either accidentally or otherwise, on top of a large block of fallen machine cut coal, such explosive not having been placed in a shot hole.”

The Commission also found that:

-

- explosives were distributed, carried, used, and stored underground in a careless manner without regard to the regulations;

- an uncertified deputy was employed in the mine contrary to the regulations;

- the mine was dusty and extremely dry and no adequate means were adopted to render the dust innocuous, as prescribed by the regulations;

- the departmental inspections were made by men without colliery experience and without the necessary equipment, and were not made as frequently as were necessary.”

The aftermath of the Mount Mulligan Mine Disaster

Following the Mt Mulligan disaster, a separate Coal Mining Act was introduced in Queensland to bring in measures to protect coal miners. In this Act, provision was made for:

-

-

- the appointment of Mines Inspectors who must have practical mining experience;

- the recording of mine deputy safety inspections in individual reports;

- specifically designed and “permitted” explosives and rules for their use in coal mines;

- the use of safety lamps or electric camp lamps for lighting for individual miners and the banning of naked lights;

- rules for the application of stone dust;

- the establishment of Mines Rescue Stations in all mining districts;

- rules for air flow and the use of ventilation fans.

-

In 2016, the disaster and loss of life was remembered 95 years later

Watch the YouTube video to hear contemporary perspective of what happened.

Many thanks to the Australian Mine Safety Journal for sharing its coverage and images of the Mount Mulligan Mine Disaster.

TapRooT®—the best root cause analysis leads to effective corrective actions

The TapRooT® System teaches you to be a very effective problem-solver. The System is a process with techniques to investigate, analyze, and develop corrective actions to solve problems. The TapRooT® process and tools are completely described in the TapRooT® Investigation Essentials Book Set.

Register today for a TapRooT® Root Cause Analysis Training Course

TapRooT® Root Cause Analysis Training courses are taught all over the world. If you are interested in learning how to stop repeat incidents, find a 2-Day or 5-Day course. Or, you may want to peruse our full course selection.

We are available to train you and your staff on-site at your workplace; reach out to discuss your needs. Call us at 865.539.2139 for any questions you may have. We are here to help you.