Problem Definition?

Can You Define a Problem Before Investigating?

I’ve read several root cause analysis systems that start an incident investigation or root cause analysis with:

- Define the problem, or

- Problem definition, or

- Scope definition, or

- Problem statement, or

- Terms of reference, or

- Identifying the problem.

Some problem definition steps are fairly straightforward. For example, watch the first minute and 30 seconds of this video…

Some of the processes have a complex problem statement or a problem definition step that includes management and investigators agreeing on boundaries for the investigation.

One example of a “Terms of Reference” is from the International Atomic Energy Agency in their document:

Root Cause Analysis Following an Event

at a Nuclear Installation: Reference Manual

It says:

The TOR (terms of reference) contains the following important elements:

- Event Title;

- Event Description (a two or three-sentence synopsis of the actual event or issue);

- Investigation Team Lead, Team Lead Department, Qualification tracking number;

- Team Members, Respective Department, number of hours per week needed from each team member for on-time completion of the investigation;

- Resources needed to complete the investigation, including monetary, materials, additional personnel, testing, or other resources needed;

- Investigation Scope – a succinct statement that captures the boundaries of the investigation – includes the failure analysis results if the root cause investigation is being performed for an equipment failure or trip;

- Interim Actions – actions taken to mitigate or prevent the issue or event until formal Corrective Actions to Prevent Recurrence can be implemented. Note: all interim actions taken or to be taken will be captured in the action tracking system, even completed actions. (The Action tracking system is a programme used to monitor the progress of completion of corrective actions identified during the event investigation process.);

- Root cause investigation milestones – commitment dates for various root cause investigation actions taken throughout the performance and approval of the investigation;

- Event Review Board disciplines necessary for RCA investigation approval – members who have the proper technical expertise and influence to understand and support corrective actions listed in the investigation;

- Sponsoring Senior Management commitment signature and date – ensures that the sponsoring manager has agreed to the root cause team, resources needed, scope, and interim actions for the successful completion of the investigation.

If the investigation scope changes during the performance of the root cause investigation, a new Terms of Reference should be completed and approved. The due date for the root cause investigation should remain as the original due date.

I thought about how lucky TapRooT® Users are. They start the investigation by planning and collecting information, and then defining the “Incident” as the worst thing that happened.

Roadblocks in the Scope of the Investigation

In a TapRooT® Root Cause Analysis, the investigator goes where the facts lead. But this isn’t true with all investigations. In some investigation scopes or terms of reference, the scope may be limited.

For example, I remember the BP investigation of the Deepwater Horizon accident. Top management (CEO Tony Hayward) set the “terms of reference” of the investigation to include only the “direct” causes of the accident. In other words, what we call “Management System” root causes would be out of bounds. This led to an incomplete and highly criticized investigation report.

I think limiting the scope of an investigation before the investigation starts is a mistake if you want to find out all the facts of what happened, all the Causal Factors, all the root causes (including Management System root causes), generic causes, and all the corrective actions needed to prevent recurrence of the incident or a similar incident.

Why Industry Leaders Choose TapRooT® Root Cause Analysis

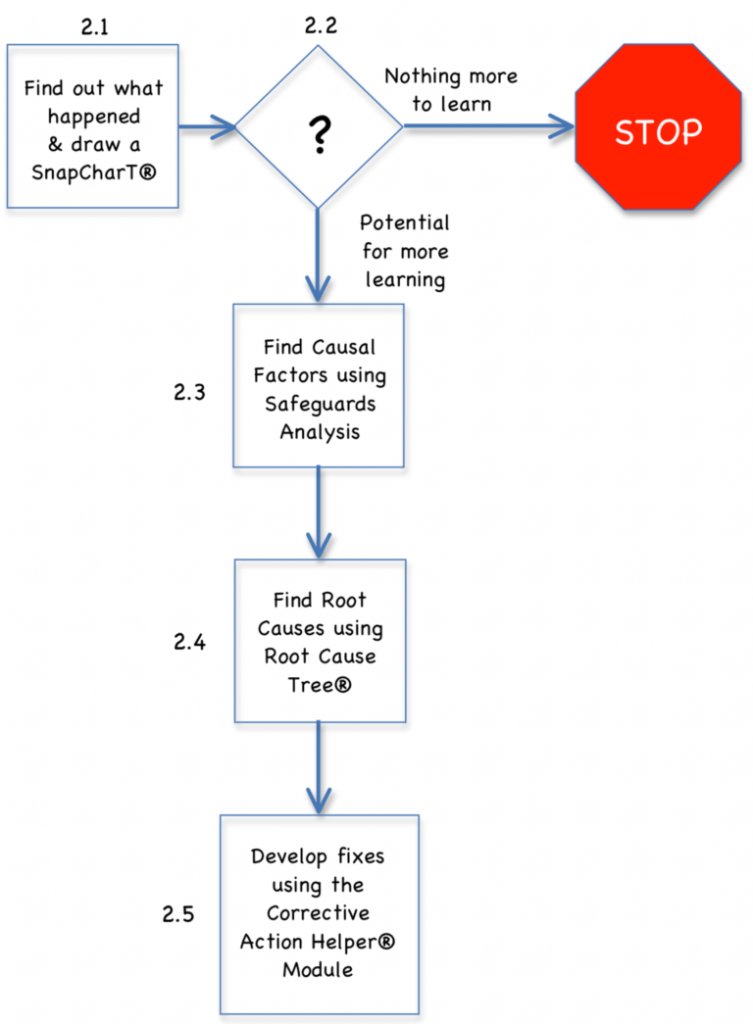

TapRooT® RCA includes a 5-Step Process for simple incidents and a 7-Step Process for major investigations (complex problems or serious accidents).

In both cases, the facts guide the investigation without predetermined boundaries.

This freedom to investigate, combined with the proprietary TapRooT Tools, guides investigations to real, fixable root causes and effective corrective actions. The successful results achieved by industry leaders are documented in our Success Stories on our blog.

For an example, watch this video…

That’s just one story. Others include:

- Stopping significant injuries and fatalities,

- Improving process reliability,

- Stopping blame,

- Positive culture change,

- Saving on workers’ compensation costs,

- Reduced equipment failures,

- Improving quality,

- Improving aviation safety,

- Reducing incident rates,

- Improving patient safety,

- Receiving industry awards for safety performance, and

- Significant cost savings,

If you would like to learn more about TapRooT® Root Cause Analysis and how it can help you solve some of your company’s most challenging issues, I recommend attending our 5-Day TapRooT® Advanced Root Cause Analysis Course. See the upcoming public course dates HERE.

Additionally, consider attending our Global TapRooT® Summit, where leading industry experts from around the world gather to share root cause analysis, performance improvement, and incident investigation best practices.

Don’t wait to get started. You need to see how TapRooT® RCA can help your company make significant improvements.