Near-Miss: How “Near” Does it Need to Be?

How “Near” Does a Near-Miss Need to Be?

What is a near-miss? The term originated with the aviation safety community. When planes accidentally came closer than a certain minimum distance but did not collide, the planes were near but missed … a near-miss. You might think of it as nearly an accident or a close-call.

But how near does a miss need to be to be called a near-miss?

USA Today published this answer to the question:

The horizontal separation standard ranges from 3 to 5 miles and drops to 1 mile under certain conditions near an airport with parallel runways.

The vertical separation is 1,000 feet for other instrument traffic and 500 feet for visual traffic.

So for pilots, the definition is clear. See some ground near-misses (and collisions) in the video below.

Also, the term near-miss is used outside the aviation industry. For example, the driving instructor below is reacting to an auto near-miss…

What about near-misses at a:

- refinery

- oil platform

- nuclear power plant

- manufacturing facility

- pharmaceutical plant

That’s a great question!

Your Definition of a Near-Miss

First, let’s start with your definition of a near-miss. Leave it as a comment below in the comments section.

I’ve heard all kinds of descriptions of what is a near-miss, and I hope we collect a variety below.

To get things started, the National Safety Council defines a near-miss as:

“…unplanned event that did not result in injury, illness, or damage – but had the potential to do so. Only a fortunate break in the chain of events prevented an injury, fatality or damage; in other words, a miss that was nonetheless very near.”

Using Safeguard Analysis to Define a Near-Miss

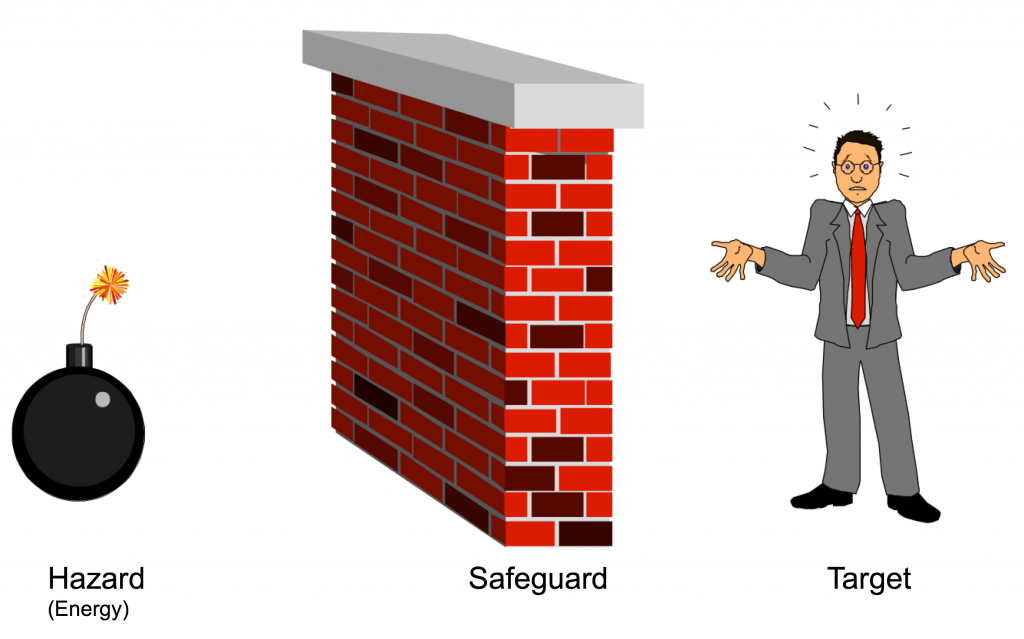

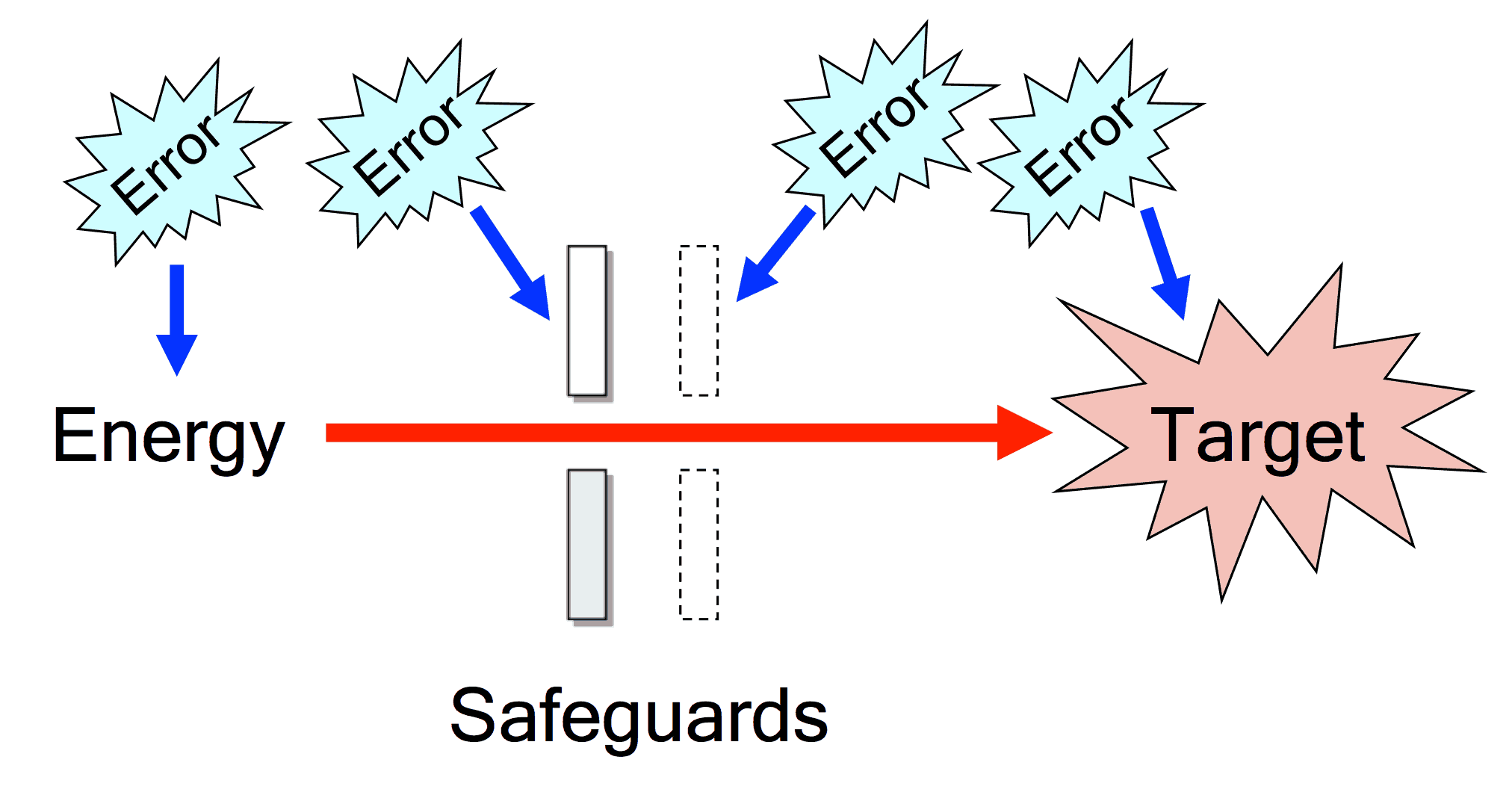

First, what is “Safeguard Analysis?” It is the analysis of Hazards (sources of energy) and Targets (things to keep safe) and the Safeguards (sometimes call Barriers) that keep the Hazard from reaching the Target.

If all the Safeguards fail, you have an accident.

In the model above, all the Safeguards have failed and allowed the Energy to reach the Target.

The cause of a Safeguard failing is a Causal Factor. Each Causal Factor has one or more root causes.

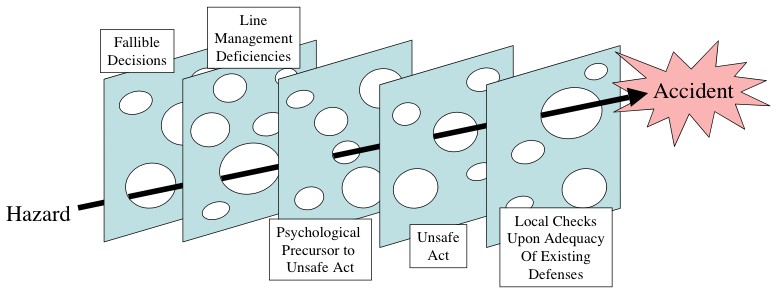

Sometimes Safeguards are shown using the Swiss Cheese Model.

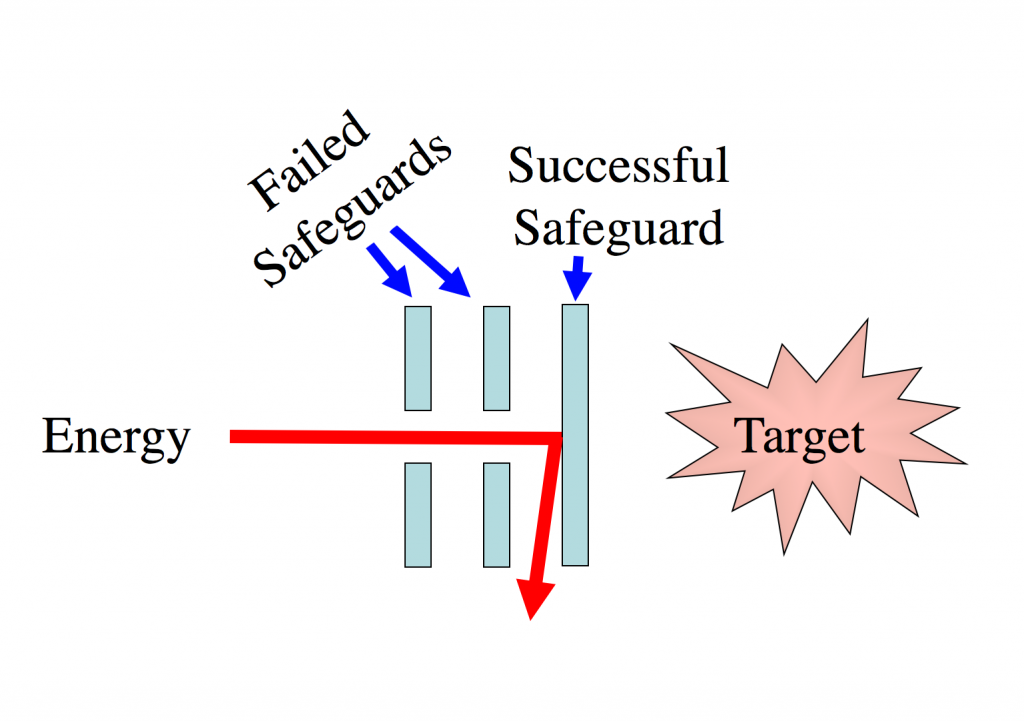

If some Safeguards fail, but one or more Safeguards are successful in preventing the Energy (Hazard) from reaching the Target (as shown below), you could call that incident a near-miss.

If you are going to use Safeguard Analysis to define your near-miss, you will have to decide how much Energy needs to be present and how many Safeguards either need to fail before calling something a near-miss.

Below is the Energy Wheel. The amount of Energy needed to call something a near-miss might depend on the type of Energy.

Does Your Definition Produce Consistent Guidance

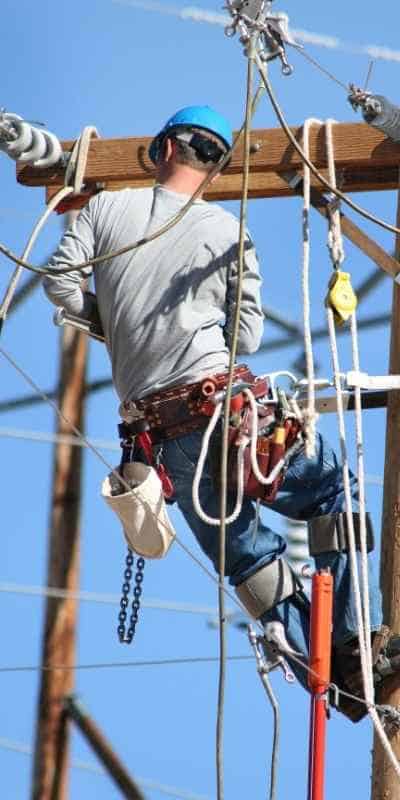

Many companies call for the investigation of near-misses. But are their definitions consistent (produce a uniform screen size)? When they consider different sources of Energy and different numbers of failed or successful Safeguards, does their evaluation result inconsistent data? Are your investigators investigating a cut finger, but not investigating a person working on a high-voltage line and narrowly misses being electrocuted (zero harm – no investigation)?

Uniform screen size should provide you with some food for thought. Is your guidance for doing an investigation across different types of hazards consistent? Maybe you should be thinking about updating your guidance on when to perform an incident investigation or near-miss investigation?

Want more guidance for your investigation policy. See Book 2, Appendix A…

Learn More About Safeguard Analysis and Root Cause Analysis

Want to learn more about Safeguard Analysis and to find the root causes of near-misses? Attend a TapRooT® Root Cause Analysis Course. See:

https://www.taproot.com/solutions/rootcausetraining/

Definition of Near Miss – something/anything is wrong/off standard but nothing has happened – yet!

More nuance about the severity of a Near Miss to determine if investigation is warrented.

Definition of Near Miss – Unexpected occurrence that threatens or could threaten personnel or facilities, systems or equipment, but has not resulted in injury or damage.

The difference between a near miss and an accident is usually a matter of luck. In a near miss, something happened but no-one was injured and nothing was damaged. In an accident, you weren’t so lucky. A near miss is never severe. The importance of a near miss can be determined by evaluating the risk exposure if you were not lucky.

Sharing Anonymously – great discussion

Near Miss Definition (for clarity between personnel safety and incident management systems)

– A incident is an unwanted event (e.g. something happened) that resulted in injury, illness or damage [incident management]

– A near miss is an unwanted event (e.g. something happened) that could have resulted in injury, illness or damage, but did not [personnel safety or incident management depending on potential]

– A hazard is any unsafe condition (e.g. something could happen) that has the potential to cause harm or damage but did not [personnel safety]

Accurate classification is critical to determine learning, sharing and investigation levels.

Additional Guidance is provided on understanding the process safety and/or personnel safety potential (risk) and thresholds on when an investigation should be performed [engaging the correct resources and levels of leadership]

Definition of Near Miss – An undesired event in the work environment that under different circumstances could have resulted in harm to people, damage to property, equipment, or the environment, or loss of business.

As a long retired safety professional I much enjoyed reading the near-miss article. I thought you might like to hear what I would call an actual near miss industrial accident.

Like many students, while in college I had to take whatever summer job I could find in order to continue my education. One summer job was working in a sheep’s wool processing plant. One of the machines pulled the wool through a large rectangular tank of near boiling hot water to extract the lanolin. One night this lanolin extraction machine became jammed and I was assigned the task of getting up on top of it and removing the jamb. I did so and then before I could get down the manager reached over and turned it back on. A metal bracket that held the finger like rods that pulled the wool through the water came down on my foot cutting a 4 inch vertical opening in the back of my leather shoe. However, it did not touch my skin nor did it bruise my heel.

To go back a minute, when I heard the machine come on and saw it start to move, while yelling to turn it off, I also moved my foot as much as possible out of the way of the machine. But not wanting to chance having my foot slip into the nearly boiling water, I actually had to choose to possibly get my foot cut or even broken vs. or a scalding. It was amazing how fast you can think in an emergency situation like that and make a choice. To this day, I would still choose getting a cut or even having a bone broken over scalding a foot in near boiling water. I was just fortunate that it turned out to be a near miss.

Thanks again for the excellent article.

Clyde