Is Normalization of Deviation Abnormal or Normal?

Why Do They Call It “Normalization of Deviation”?

I’ve seen many people (CLICK HERE for one recent example) claim that Dr. Diane Vaughan, sociologist, coined the term “Normalization of Deviation.”

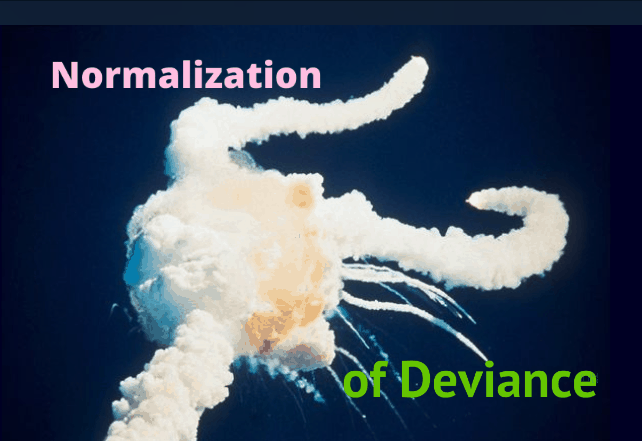

But what is “Normalization of Deviation?” It is a gradual, almost imperceptible, slide into accepting risks that previously would have been unacceptable. This acceptance of risk is most likely caused by production pressure from above and causes workers to take seemingly accepted shortcuts. Dr. Vaughan’s work was used to explain the management decisions that resulted in NASA’s Challenger accident (January 28, 1986).

But is deviation abnormal? Or is deviation normal? Is the absence of deviation the actual abnormal state? I once wrote that there is no such thing as the normalization of deviation. That article created quite a bit of discussion.

But the most important part of the whole study of deviation is … What does management need to do to assure that deviation does not occur?

Stopping Normalization of Deviation

When PhDs discuss the normalization of deviation, they often get into complex discussions that include words like:

- institutional persistence,

- culture and cognition,

- agency,

- socio-technical systems,

- institutional environment,

- architecture, technology, task, and culture of the workplace,

- institutional contingencies,

- weak signals,

- system mandates, and

- resilience.

These complex discussions are then simplified to communicate how to prevent the normalization of deviation to people in the field. An example is the “Dirty Dozen” causes of U.S. Army aviation mishaps causes…

An example of the oversimplification of the topic is that to prevent the cause of number 9: “Failure to Enforce Published Rules,” the corrective action would be to “Always enforce standards” and “Do not allow practice to become the standard (normalization of deviation).”

These actions seem to be the opposite of the Nike “Just Do It!” slogan. The Army slogan would be “Just Don’t Do It.” But I find this approach fairly useless. What would I suggest? Read on for some ideas.

High-Reliability Organizations Don’t Allow Deviation

My experience was gained in the first high-reliability organization – the Nuclear Navy. The culture and standards set for the Nuclear Navy came from the top down – from Admiral Rickover.

How did he communicate and enforce these high standards that didn’t allow the normalization of deviation? That’s the topic of two sessions in the High-Reliability Organization Best Practices Track at the 2025 Global TapRooT® Summit.

The first session is…

Ken Reed, Justin Clark, Mark Paradies, and Gard Clark (all former Navy Nukes) will discuss their personal experiences performing or being on the receiving end of Nuclear Navy inspections and peer reviews that were used to communicate and enforce the high standards of the Nuclear Navy. This will be a panel discussion session to allow questions and discussions to share knowledge among the speakers and the attendees.

The second session is…

What were Admiral Rickover’s standards and and how did he establish them? Don’t be misled by academic studies of high-reliability organizations performed by people who have never achieved high reliability. Mark Paradies, the speaker for this session, will bring his first-hand knowledge of the Nuclear Navy to this session. Mark was interviewed by Admiral Rickover, served on two nuclear-powered ships, was qualified as an “Engineer” by NAVSEA 08 (the headquarters Nuclear Navy organization), and has studied Rickover’s methods for decades. Mark is someone who has been there and paid the price. He will explain why achieving high reliability is so difficult that most organizations don’t come close.

In addition, the High-Reliability Organization Best Practices Track had seven more sessions to share high-reliability best practices. The outline for the complete track includes…

Attend the 2025 Global TapRooT® Summit

So, to learn the secrets of avoiding normalization of deviation and to learn best practices to achieve high reliability, plan on attending the High Reliability Organization Best Practices Track at the 2025 Global TapRooT® Summit being held in Knoxville, Tennessee, from October 1-3. For more information, CLICK HERE.

Also, don’t forget about the pre-Summit Courses on Monday – Tuesday, September 29-30. CLICK HERE to see the 11 pre-Summit Courses that you can choose from.

Finally, you can customize your Summit experience when you register for the Summit by choosing sessions in any of the eight best practice tracks. To see all the sessions available, CLICK HERE.

To pick your track or choose individual sessions, click on the link below to register.

Click Here for

Summit Registration