How Do You Use TapRooT® RCA for a Quality Issue?

What is a Quality Issue?

All industries and service companies can have quality issues. For example…

- A pharmaceutical company could be non-compliant with FDA regulations.

- A telecommunications company could have an outage of its 911 service.

- A refinery could ship the wrong product to a customer.

- A manufacturing company could ship a product with a defect.

- A hospital could give a patient the wrong drug.

- An airline could have a delayed flight that causes passengers to miss their connections.

- A utility could have a power outage that leaves its customers without power.

All of these would be viewed a a negative outcome by the customers and, in some cases, the regulator.

How does the company know what to do to prevent a recurrence of these problems? That’s easy. Advanced root cause analysis is the answer.

Applying Advanced Root Cause Analysis

In each case above, there is a sequence of events that led to the quality issue. In that sequence of events and the conditions that explain the sequence, there are causal factors (things that went wrong) that ultimately lead to the quality issue. Each causal factor may have one or more root causes that, if corrected, will prevent a recurrence of the quality issue.

But how do you understand the sequence of events, the causal factors, and the root causes, and then develop effective fixes? That’s the job of the TapRooT® Root Cause Analysis System (advanced root cause analysis). The process for simple issues is shown below…

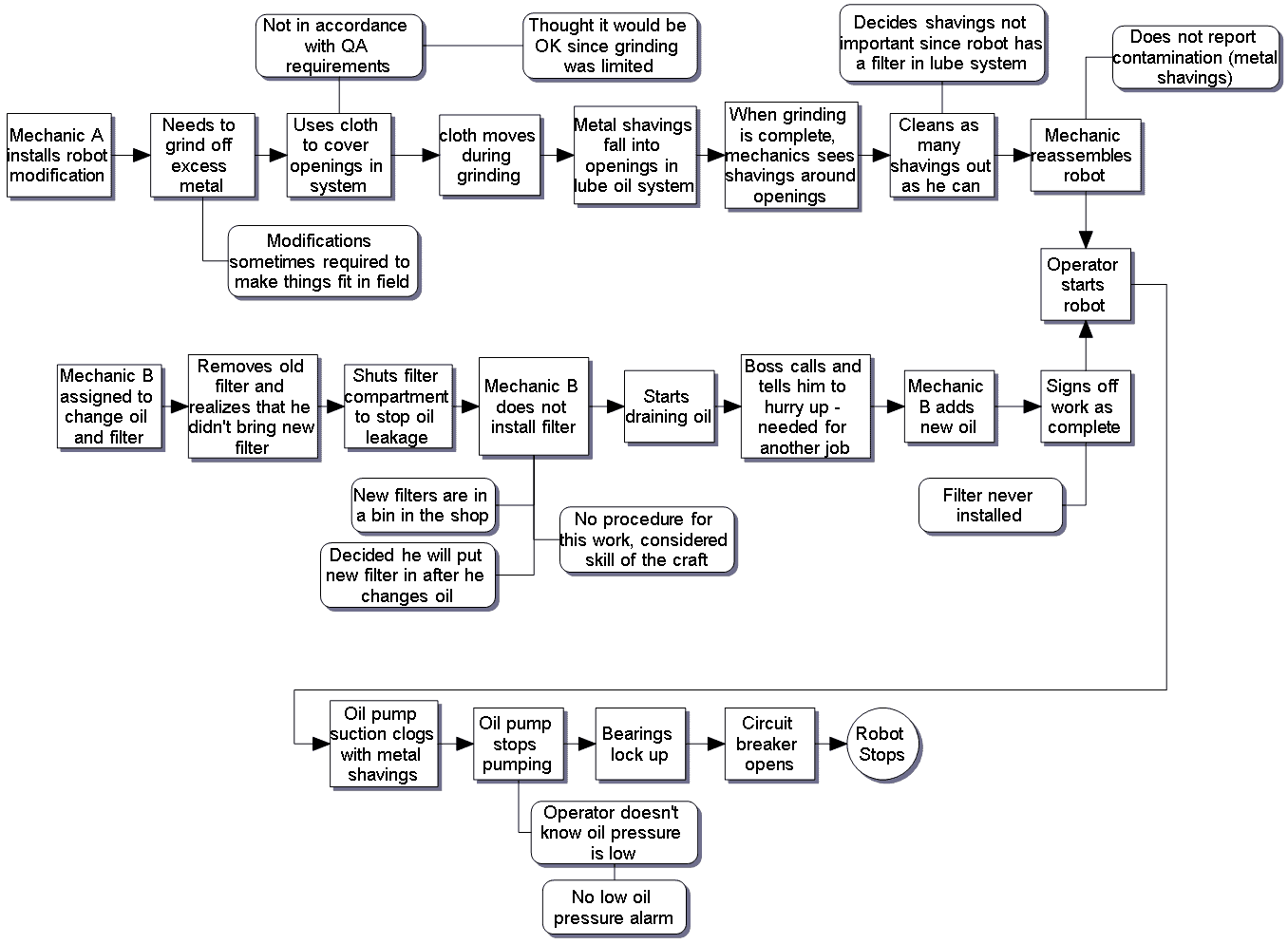

TapRooT® RCA begins with the development of an easy-to-understand sequence of events, conditions, and causal factors, called a SnapCharT® Diagram (an example is shown below)…

Next, the TapRooT® System uses the Root Cause Tree® Diagram to find the real root causes of the issues (causal factors). A portion of the tree (the Human Engineering Basic Cause Category) is shown below…

Once all root causes for all causal factors have been identified, one is ready to identify effective fixes using the Corrective Action Helper® Guide.

This whole process is computerized in the patented TapRooT® Software.

The results of this process are sure to keep your management and regulators happy when they understand what happened and the corrective actions to prevent it from happening again.

Learn More About TapRooT® Root Cause Analysis

The easiest way to learn more about TapRooT® Root Cause Analysis Training and how it can help you improve quality, safety, equipment reliability, and operational excellence is to attend one of the TapRooT® Courses. See the list of upcoming course dates and locations HERE.