Rickover’s Essential Elements of Excellence in Process Safety

Process Safety Progress Article

In 2011, the Center for Chemical Process Safety launched “Vision 20/20” to describe how process safety excellence can be achieved through collaboration between industry, researchers, regulators, academia, and communities worldwide. In August of 2025, Process Safety Progress published a new article (Excellence in Process Safety) to highlight the themes of the original Vision to people and companies new to process safety and to refresh those themes while making it clear how the Vision relates to CCPS Risk-Based Process Safety.

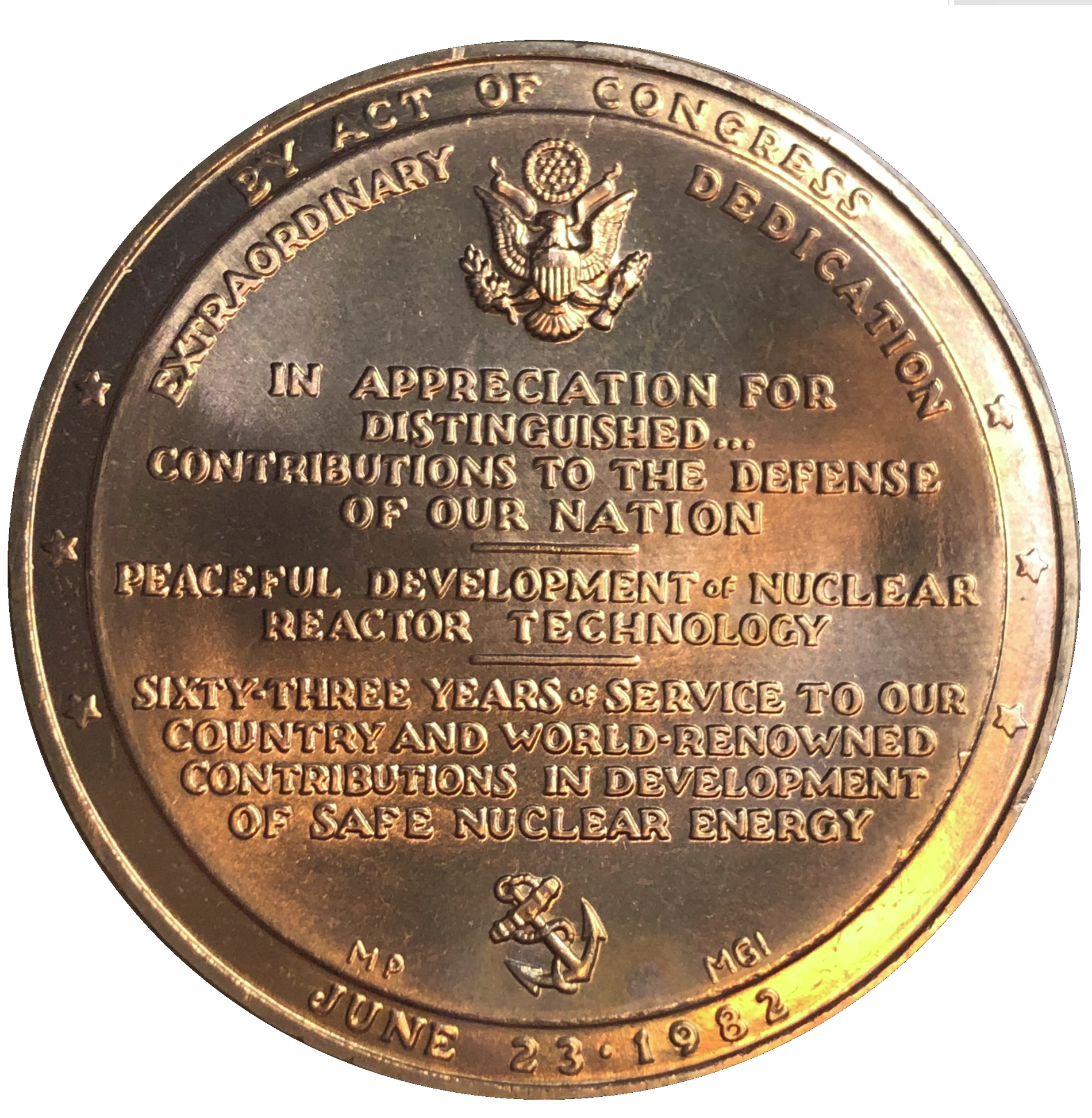

I read the article and was amazed at how many tenets were related to Admiral Rickover’s reactor safety philosophy, which was developed in the 1950s/1960s. I have explained that philosophy in a previous article (CLICK HERE FOR MORE). Additionally, I wrote an article in 2011 about how Rickover’s philosophies were lacking in process safety improvement efforts. It was called “Has Process Safety Management Missed the Boat” and is available for download HERE.

I called Rickover’s efforts the “Normalization of Excellence.” I will explain some of the similarities and differences below.

The Five CCPS Tenets of Excellence in Process Safety

To compare Rickover’s philosophies with the CCPS Process Safety Excellence initiatives, I will need to provide a brief overview of both.

The five tenets of Excellence in Process Safety are:

- Committed Culture

- Vibrant Management Systems

- Disciplined Adherence to Standards

- Intentional Competency Development

- Enhanced Application and Sharing of Lessons Learned

The CCPS’s first tenet of Excellence in Process Safety is “Committed Culture.” A brief description on the CCPS website says:

In a Committed Culture, executives involve themselves personally, managers and supervisors drive excellent execution every day, and all employees maintain a sense of vigilance and vulnerability.

This includes:

- Executives are personally involved in process safety.

- Operational discipline.

- A sense of vulnerability.

The second tenet is “Vibrant Management Systems.” The CCPS website says:

Vibrant Management Systems are ingrained throughout the organization. Vibrant systems readily adapt to the organization’s varying operations, and risk systems are ingrained throughout the organization. Vibrant systems readily adapt to the organization’s varying operations and risks.

The management system:

- Is documented, accessible, and easily used,

- Defines how operations are conducted at the workplace,

- Promotes safety in design, operations, and maintenance, and

- Is agile and continuously improved.

The third tenet is “Disciplined Adherence to Standards.” The CCPS website says:

Disciplined Adherence to Standards means using recognized design, operations, and maintenance standards. These standards are followed every time, all the time, and are continually improved.

The website explains that:

- Companies identify, document, and diligently follow standards for new designs.

- Companies also identify, document, and diligently follow a set of standards applicable to existing equipment. These standards for existing equipment set the minimum expectations for design, operations, and maintenance.

- Companies identify and manage process safety risks arising from gaps against these standards.

- As industry standards evolve, companies codify significant new learnings in their identified standards for existing equipment.

The fourth tenet is “Intentional Competency Development.” The CCPS website says:

Intentional Competency Development ensures that all employees who impact process safety are fully capable of meeting the technical and behavioral requirements for their jobs.

The website explains:

- The bottom line: no matter how good the culture or management system is, or how well the company adheres to standards, it takes competent employees to implement those systems and standards.

- This requires intentional competency development, which includes understanding competency expectations, providing educational resources, and allowing time for people to build competency.

- Intentional competency development applies to all levels in the organization. Competency includes engineers implementing technical designs, operators knowing their process and safe operating limits, and leaders visibly leading process safety.

The fifth and final tenet is “Enhanced Application & sharing of Lessons Learned.” The CCPS website says:

Companies use various assessment techniques to ensure their process safety management systems are working as intended.

The website explains that:

- It will become standard practice for companies to supplement internal audits with competent third-party verification of their engineered systems and process safety management systems.

- Third-party technical experts verify specific technical details.

- Public and non-governmental organizations evaluate implementation of company process safety programs.

Rickover’s Three Essential Elements and 18 Additional Elements

First, Rickover explained three essential elements to Congress. The three essential elements are:

See detailed description of each of these key elements by clicking on the links above.

In addition to these three keys, Rickover identified 18 other elements that he considered indispensable. I won’t describe them in detail, but I will list them here:

- Conservatism of Design

- Robust Systems (design to avoid accidents and emergency system activation)

- Redundancy of Equipment (to avoid shutdowns and emergency actions)

- Inherently Stable Plant

- Full Testing of Plant (prior to operation)

- Detailed Preventive/Predictive Maintenance Schedules Strictly Adhered To

- Detailed Operating Procedures Developed by Operators, Improved with Experience, and Approved by Technical Experts

- Formal Design Documentation and Management of Change

- Strict Control of Vendor-Provided Equipment (QA Inspections)

- Formal Reporting of Incidents and Sharing of Operational Experience

- Frequent Detailed Audits/Inspections by Independent, Highly Trained/Experienced Personnel that Report to Top Management

- Independent Safety Review by Government Authorities

- Personal Selection of Leaders (looking for exceptional technical knowledge and good judgment)

- One Year of Specialized Technical Training/Hands-On Experience Before 1st Assignment

- Advanced Training for Higher Leadership Positions

- Extensive Continuing Training and Requalification for All Personnel

- Strict Enforcement of Standards & Disqualification for Violations

- Frequent Internal Self-Assessments

Would you like to review what Rickover had to say about them? See his testimony to Congress here:

What Are the Differences?

FIRST, when you compare the CCPS’s “Intentional Competency Development” to Rickover’s Technical Competency,” you may think they are similar. But Rickover’s “Technical Competency” goes far beyond the CCPS quote of leaders “visibly leading process safety.” In Rickover’s nuclear power program, managers (including “senior executives”) had years of technical training, testing, and qualifications before they could become a senior executive (a Commanding Officer of a sub or a ship). I am not aware of any rigorous program to qualify executives in the technical aspects of plant operations, as well as process safety theory, in any process safety-related industries.

SECOND, Rickover proposes “Total Responsibility.” This may be partially covered by the “Committed Culture” aspect of the CCPS’s five elements. However, if you read the information at the TOTAL RESPONSIBILITY link, you may find that Committed Culture is not the same as Total Responsibility.

As an example, I often refer to the Deepwater Horizon accident. The Washington Post had this to say about the oil industry’s idea of Total Responsibility:

“Three major oil industry executives agreed on one thing in a pair of

Senate hearings Tuesday: Someone else was to blame for the drilling rig

accident that triggered the massive oil spill in the Gulf of Mexico.”

Without Rickover’s unique concept of total accountability/responsibility, people can sidestep responsibility and blame others. Without full accountability/responsibility, decisions to:

- cut budgets,

- reduce staffing,

- defer maintenance,

- opt for cheaper designs,

- or shortcut company requirements

are easy to make because no one person is responsible. They are just “risk-based decisions” made by underlings without the knowledge of senior executives.

As Philippe Paquet wrote:

“When everyone is responsible, no one is responsible.”

Therefore, as Rickover points out, you must have one person at the top clearly responsible for reactor (process) safety, or no one is responsible, and you will NOT be able to achieve excellence.

FINALLY, we come to “Facing the Facts.” This was probably the most important of Rickover’s three essential elements. Of course, you need the technical knowledge and total responsibility to face the Facts. However, unless you face the facts, you will never truly prioritize reactor (or process) safety.

I don’t think that Facing the Facts is totally covered by the CCPS’s Vibrant Management Systems and Disciplined Adherence to Standards. The article published in Process Safety Progress actually says:

“It is recognized that standards do not exist for all types of equipment and engineering practices. Risk decision-making is used when applicable standards do not exist.”

In the Facing the Facts description, I give two examples of Rickover personally “Facing the Facts.” In both of these cases, there were no existing standards. Read the examples at the Facing the Facts LINK to understand what Rickover meant.

How did Rickover make these decisions? Here is what he had to say:

“I have a son. I love my son. I want everything that I do to be so safe

that I would be happy to have my son operating it.

That’s my fundamental rule.”

Is that a risk-based decision?

Note that he made these decisions when his organization (Naval Reactors) was on a tight budget and he was fighting to stay in the Navy and not be forced to retire by more senior Admirals (he was only a Captain at the time). He faced the facts, was successful in developing nuclear-powered submarines (beating the Russians), and was recognized by Congress, a Congress that forced the Navy to promote Rickover to the rank of Admiral.

In almost every major process safety accident, management failures to face the facts are found. Do these accidents represent a robust culture of Vibrant Management Systems and Disciplined Adherence to Standards that CCPS proposes? Or is the industry’s interpretation and implementation of the CCPS elements inadequate?

Don’t forget that there are 18 more essential elements in Rickover’s philosophy. To read the complete testimony of Rickover to Congress, CLICK HERE.

One final Rickover quote from his cCongressional testimony:

Properly running a sophisticated technical program requires a fundamental understanding of, and commitment to, the technical aspects of the job and a willingness to pay attention to the technical details. I might add, infinite personal attention.

This can only be done by one who understands the details and their implications. The phrase, “The devil is in the details,” is especially true for technical work. If you ignore those details and attempt to rely on management techniques or gimmicks, you will surely end up with a system that is unmanageable, and problems will be immensely more difficult to solve. At Naval Reactors, I take individuals who are good engineers and make them into managers. They do not manage by gimmicks, but rather by knowledge, logic, common sense, hard work, and experience. Once again, this emphasizes the need for senior executive involvement in the fundamental technical details of advanced technology operations.

Once again, this highlights the importance of senior executive involvement in the technical details of advanced technology operations. And I believe all process safety-related industries rely on advanced technology.

What Could the Nuclear Navy Improve?

Not everything in the Nuclear Navy was (or is) perfect. The dark side of total responsibility was a culture that emphasized blame and shied away from accountability. Additionally, sailors and officers frequently worked grueling hours, leading to excessive fatigue. Plus, the Nuclear Navy needed advanced root cause analysis.

Why haven’t these problems been fixed by an advanced learning organization? Perhaps the saying:

“We have always done it this way.”

could be hindering progress? Or, does the Nuclear Navy believe they don’t need to improve further? (I’ve heard more than one Admiral explain that they already understand root cause analysis when I know they aren’t using the most advanced techniques.)

Thus these problems will wait for another day to be solved.

What Do You Think?

Are there elements of Rickover’s nuclear safety philosophy that are missing from even the most advanced process safety excellence efforts? Does your company need to adopt some of Rickover’s essential elements to improve their process safety performance?

Let me know your thoughts in the comments below.