Four Sure Signs You Need to Improve Your Root Cause Analysis

Do You Need to Improve Your RCA?

Some people think that their incident investigations and root cause analysis is good enough. Of course, I don’t see it that way. I think there is always room for improvement. So, how can you tell if your root cause analysis really needs improvement? There are four sure signs…

- Your facility or company has repeat incidents (or even worse, repeat accidents).

- Your management is dissatisfied with the results of your root cause analysis.

- Your regulator is dissatisfied with your root cause analysis and corrective actions.

- Your investigators are dissatisfied with the RCA system you are using and want to try something new.

Read on if you want to know more about these signs that indicate that your root cause analysis needs improvement.

1. Your Facility or Company Has Repeat Incidents.

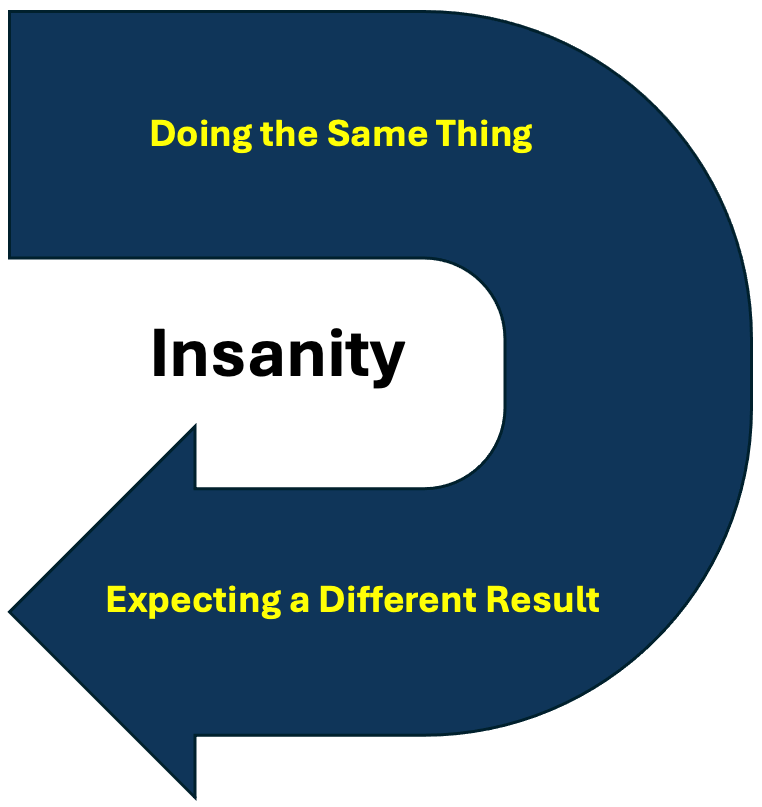

What is the definition of insanity?

Yes, if you keep having the same incidents over and over again, you may be insane! Or maybe you are just driving your management insane?

Repeat incidents/accidents are a sure-fire indicator that your root cause analyses and corrective actions need improvement. Failure to improve is a performance indicator that you can’t ignore.

2. Your Management is Dissatisfied with the Results of Your RCA.

When your boss, your boss’s boss, or your boss’s boss’s boss doesn’t like the results of a root cause analysis, you have a big problem. It might be that your root cause analysis is inadequate. Or, it might be that your management doesn’t understand root cause analysis and effective corrective actions, and they need some root cause analysis training for management (see THIS LINK).

3. Your Regulator is Dissatisfied with Your RCA.

It is never good to be at odds with your regulator. Fines will eat into your company’s profits. Rare but significant legal troubles are the worst outcome for your management and public relations.

I’ve seen the US FDA, EPA, NRC, OSHA, MSHA, BSEE, and other regulators (as well as state agencies) cite poor root cause analysis during inspections and incident investigations.

Therefore, the system you choose for root cause analysis should produce answers that keep your regulator happy.

4. Your Investigators are Dissatisfied with the Company’s RCA System.

Yes, I’ve seen this too many times. For whatever reason, investigators are forced to use a root cause analysis system that just doesn’t work. Need some examples?

- Blame-oriented systems/causes

- 5-Whys

- Incomplete checklists

- Homegrown systems that are behind the times

- Systems that don’t provide guidance (just have an open mind)

That’s just a sample.

Sometimes, investigators are dissatisfied because they are assigned to investigate incidents in their “spare time.” Everybody’s plate is full, and I don’t know anyone who wants extra work. So, make sure your investigators have time designated to perform root cause analysis.

Are You Ready to Improve?

Here is the first thing to try – Advanced Root Cause Analysis Training. And what training do I recommend? TapRooT® Root Cause Analysis Training.

We have taught the 2-Day, 3-Day Virtual, 5-Day, and Equifactor® Training to tens of thousands of satisfied users around the world. The TapRooT® System has been adopted as a standard by leading companies in a wide variety of industries. And TapRooT® Training comes with a GUARANTEE:

GUARANTEE

Attend a TapRooT® Course, go back to work, and use what you have learned to analyze accidents, incidents, near-misses, equipment failures, operating issues, or quality problems. If you don’t find root causes that you previously would have overlooked, and if you and your management don’t agree that the corrective actions that you recommend are much more effective, just return your course materials, and we will refund the entire course fee.

Where else can you find such a rock-solid guarantee? You can feel assured when you select TapRooT® Root Cause Analysis Training.

For Complete information about TapRooT® Training, see THIS LINK.

For people who have adopted the TapRooT® System and want to improve their implementation of TapRooT® RCA, I suggest attending the TapRooT® Summit. There is a Best Practice Track specifically oriented toward best practices in investigations and root cause analysis. For complete Summit information, CLICK HERE.

NOW is the time to get started making improvements BEFORE your management, regulator, or investigators become dissatisfied. Don’t have repeat incidents. Use effective TapRooT® Root Cause Analysis to resolve your problems once and for all.