2025 Pre-Summit Courses

What Does a Pre-Summit Course Look Like?

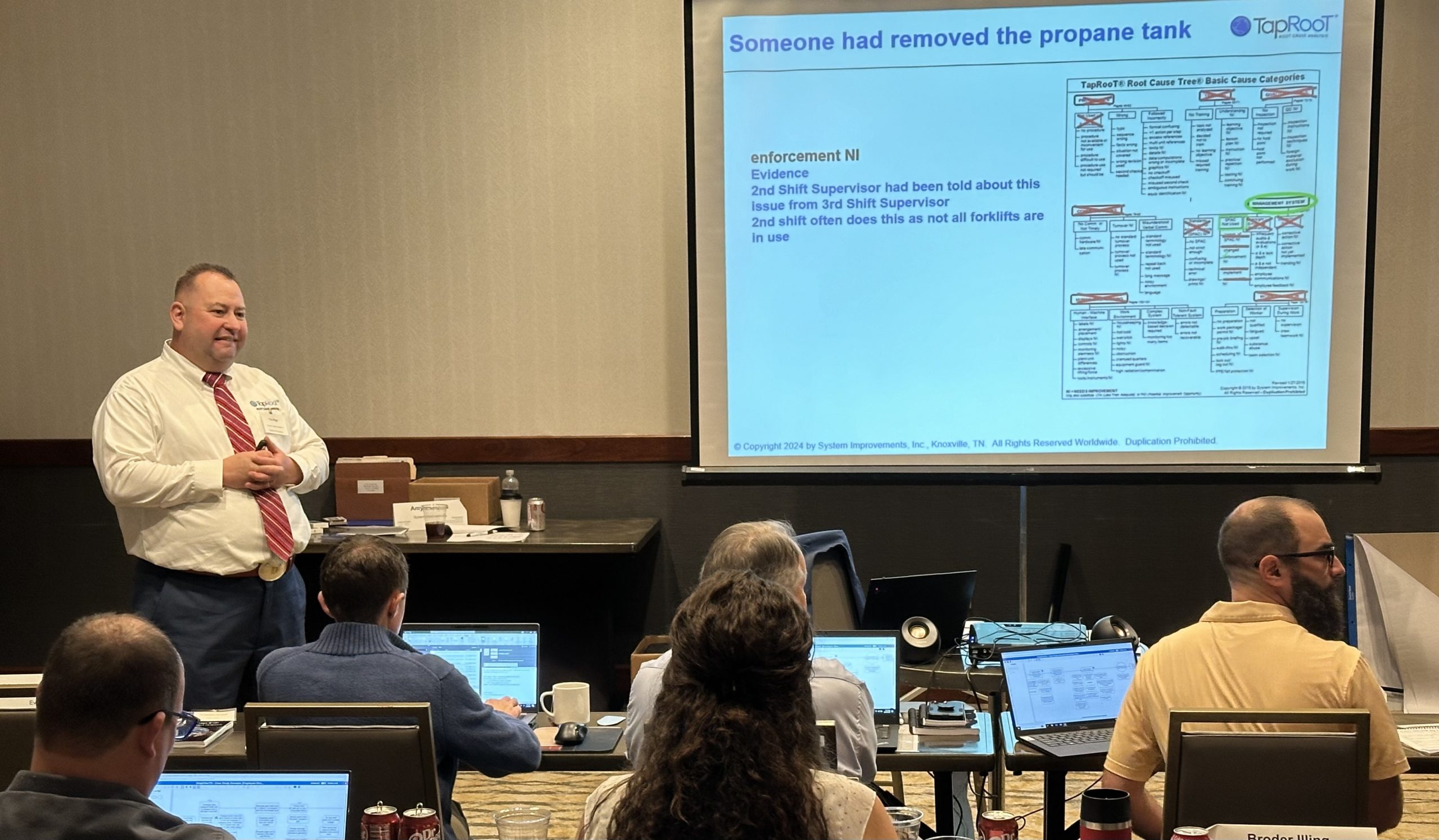

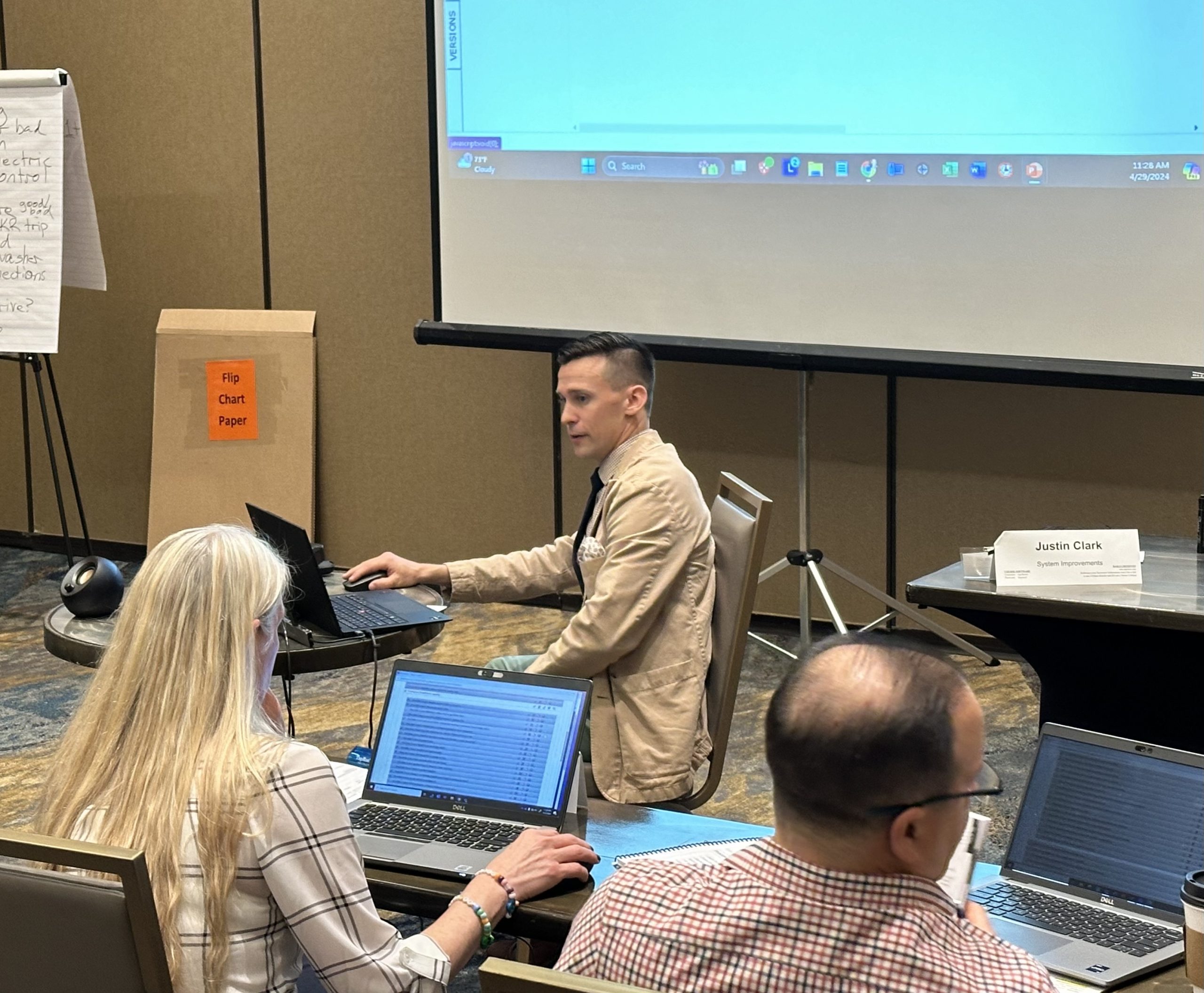

If you are wondering what the 11 optional pre-Summit Courses will look like at the 2025 TapRooT® Summit being held in Knoxville, TN, on September 29 – October 3, here are some pictures of previous courses and a brief description of each of the 11 courses being held this year…

Auditing & Proactive Improvement

This course helps people understand how to use advanced root cause analysis tools to develop their audit protocols and use the human performance and equipment reliability knowledge that is built into the TapRooT® Root Cause Tree® Diagram to understand the root causes of conditions adverse to quality, including non-conformities and non-compliance issues.

Applying TapRooT® Root Cause Analysis proactively when auditing can help your company avoid quality issues, incidents, equipment failures, and accidents by being more effective in your audit processes.

TapRooT® Advanced Case Study Workshop

This course is for previously trained TapRooT® Users who would like to refresh/improve their skills by studying unique case studies. The advanced skills learned in the course can be applied to all types of TapRooT® RCA investigations.

The objectives of this 2-day training workshop are to deepen the attendees’ understanding of TapRooT® RCA, teach new ways of applying TapRooT® RCA to their investigations, learn advanced root cause analysis skills, go beyond basic safety examples, and discover new TapRooT® software features.

Advanced Communication and Presentation Skills

Communication/presentation isn’t a side skill; it’s a critical safety and quality tool. And an absolute necessity for Certified TapRooT® Instructors. And like any tool, it can be sharpened. Presented by Vincent I Phipps, this course will help you sharpen skills that you might not even know that you have.

Through interactive sessions and real-world insights, you’ll walk away with the tools to improve your investigation communications, ask better questions, make clearer recommendations, and drive a culture of accountability and safety.

Stopping Human Error

Do you…

- Want to learn the most effective human performance improvement techniques and which ones are counterproductive? (Yes, some techniques don’t work!)

- Need methods you can apply to effectively stop major accidents and incidents by “stopping” human error?

- Really need to achieve excellent human performance?

- Need a plan to reduce human error?

If you answered “Yes!” to any of the above, we invite you to our upcoming Stopping Human Error Course.

The course will help you understand:

- The causes of human error

- Human factors design best practices

- Methods to find error-likely situations

- Techniques to help supervisors and workers prevent human errors

- CHAP (Critical Human Action Profile)

- Human Performance Improvement Technology

- Conservative decision-making

- How automation influences human error

- Designing your human performance improvement program.

With the exercises that provide an opportunity to try the techniques, this is an active, quick-moving course that will help you develop a customized, effective, efficient program to improve human performance at your facility.

TapRooT® Software Training

Did you know that version 6.18.0 will come out just after the 2025 TapRooT® Summit? To get the most from your TapRooT® VI Software Version 6.18.0, you need to learn how to:

- Create your own Custom Tabs, fields, and pick lists.

- Design and build reports.

- Select Global preferences for your company, including Language options.

- Select SnapCharT® preferences for yourself.

- Design and embed a lessons learned program into the software.

- Use Optional investigation techniques.

Dan Verlinde, Chief Technology Officer, and Angie Comer, Software Project Manager, will teach an intensive outline of the TapRooT® VI Software. Whether you are a System Administrator or a TapRooT® user, you will learn all the capabilities built into this amazing software. Don’t get just 10-20% from your software investment. Learn the full power of your TapRooT®Software!

Equifactor® Equipment Troubleshooting & TapRooT® RCA

Equifactor® Troubleshooting is for maintenance technicians, equipment reliability specialists, maintenance managers, and non-equipment expert investigators to help them develop best-in-class performance by asking best-in-class questions.

Imagine the downtime prevented and money saved by using true first-time fixes and NOT having repeat equipment failures. If this sounds interesting (and worthwhile), then Equifactor® Equipment Troubleshooting & TapRooT® Root Cause Analysis is for you.

Equifactor® Troubleshooting Techniques are based on the work of the late equipment reliability expert Heinz Bloch and capture how Best-in-Class organizations think differently about their equipment and systems. Attend the course and learn to think differently about how to investigate equipment failures.

Effective Interviewing & Evidence Collection

The TapRooT® Root Cause Analysis System and ASTM International Standards are the solid foundation of this evidence collection training. Attendees will:

- Learn how to preplan and prepare to document investigations with ease.

- Use a SnapCharT® efficiently as a planning tool for evidence collection.

- Work in teams using a systematic process to collect information.

- Learn how to best label, collect, and record evidence.

- Learn how to conduct an initial site visit.

- Participate in mock interviews, practicing the TapRooT® 12-Step Interview Process.

Don’t miss this chance to sharpen your interview and evidence collection skills.

Developing an Incident Command System

Those who serve on emergency response teams need the ability to quickly assess the complexities of the incident, using their sense of hazard awareness to respond with decisive action and direct a cohesive response effort. If these important skills are not deliberately cultivated and drilled, a workplace emergency can quickly become a far more serious situation.

In this course, attendees will use the essentials of the 2-Day TapRooT® Course and gain the fundamentals of incident command and control, using SnapCharT® Diagram to build tabletop drills with the key response components. They will also use the Root Cause Tree® Diagram and Dictionary and Corrective Action Helper® Module to identify opportunities for improvement based on human performance during drills and emergencies.

These tools will give first responders, operations personnel, and people in refining, chemical, and industrial settings the tools needed to take charge and direct their team members to effectively address various aspects of an emergency.

Measurement, Trending, and Predictive Analysis

In this 2-day workshop, you will learn how to:

- Identify leading counts and ratios that best reflect the ‘vital signs’ of process performance.

- Set up a simple process to capture and crunch daily process information.

- Review and use measurement results daily to predict, anticipate, and improve performance.

- Recognize and engage team members in effective daily measure use.

- Select options to improve the design of your existing measurement work system.

The tested and proven measurement work system designs we share in this workshop will help you significantly improve how you measure, analyze, and improve daily work. Each participant leaves with an action plan for improving their process measurement and analysis processes and a preliminary set of vital signs for those key processes they are responsible for improving.

Analyzing and Fixing Safety Culture

Do you believe you are doing a good job of your root cause analysis, investigations, and corrective actions? Yet these actions don’t seem to work or grow as effectively as you might have thought. You may be missing some underlying cultural traits that are limiting your efforts to improve your safety culture.

During the program, each participant will be completing a Human Synergistics Organizational Cultural Inventory© Survey and a Human Synergistics Organizational Cultural Inventory© Ideal Survey. These tools will help you gain detailed insight into your company’s culture and, more importantly, what organizational outcomes this culture will cause. Utilizing the knowledge gained from these surveys, corrective actions will be developed using RCA as well as cultural attributes. At the end of the session, breakout groups will use their own examples and their own cultural results to work through the TapRooT® process and create corrective actions.

Upon returning to your office, you will better understand what may be going on culturally at different levels in your organization, and more importantly, how to effectively improve performance. Improving performance can be difficult, as we all know; however, the deeper knowledge gained from the material discussed will help make future improvements more effective.

TapRooT® Root Cause Analysis Course

The 2-Day TapRooT® Root Cause Analysis Course focuses on the essential TapRooT® Techniques needed to investigate low-to-medium risk incidents and precursor incidents. Our 5-Step investigation Process simplifies TapRooT® to make the investigation efficient yet effective. The training focuses on understanding what happened, identifying Causal Factors, analyzing the Causal Factors using the Root Cause Tree®, and developing effective fixes using the Corrective Action Helper® Guide.

Don’t miss this chance to learn effective, advanced root cause analysis in a course that tens of thousands of attendees have praised for how much they learn in such a short time.

Learn more about the Summit and the pre-Summit Courses

CLICK HERE to learn more about the Summit (October 1-3) and the pre-Summit Courses (September 29-30) being held in Knoxville, TN.

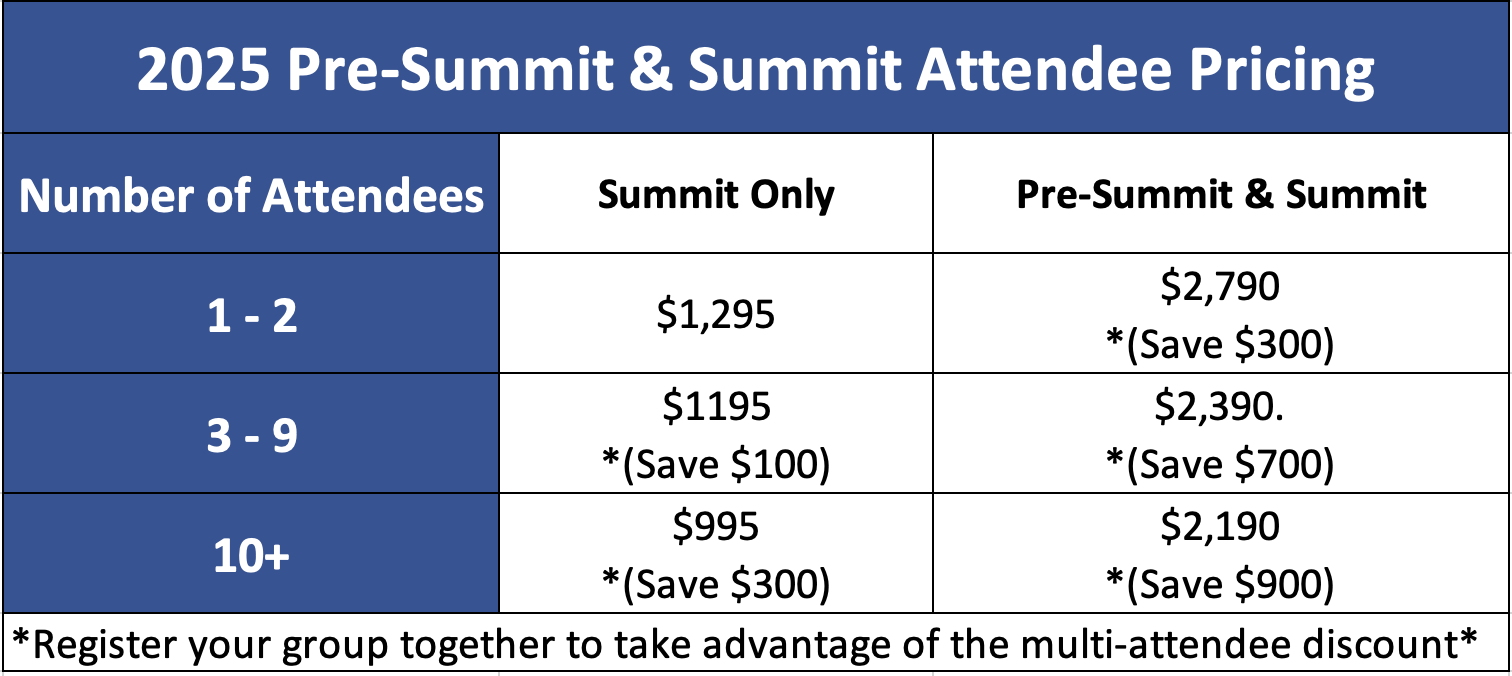

See below for the potential discounts when you attend both a pre-Summit Course and the Summit or if you bring a team.

Register by CLICKING HERE.