Dash 8 Turboprop Fails to Pressurize Amid a Series of Missteps & Misassumptions

On Saturday morning, November 20, 2021, a Maroomba Airlines Dash 8 turboprop left Perth, Australia, as a charter flight to Port Hedland, Western Australia.

Approaching 10,000 ft. after takeoff, the Dash 8 flight crew observed the turboprop’s cabin had not pressurized. At this altitude, oxygen masks were not needed, but attempts to rectify the problem in flight were unsuccessful, and the flight crew opted for an immediate return to Perth.

The ATSB investigation found Maroomba’s operations personnel incorrectly interpreted a message from the engineering department regarding the aircraft’s maintenance status, and it remained assigned to the charter flight.

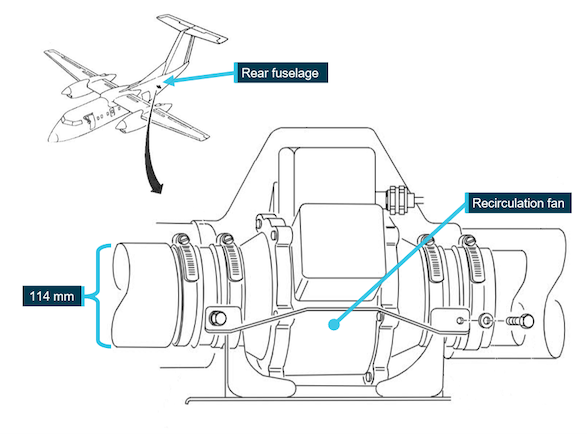

“It was found the Dash 8 turboprop failed to pressurize because its recirculation fan had been removed during maintenance the day prior, and this meant that the cabin was not fully sealed,” ATSB Director Transport Safety Dr. Michael Walker said.

“This allocation also remained on the flight crew’s roster and the flight manifest, which contributed to the flight crew’s confidence that the aircraft was serviceable,” Dr. Walker said.

“As there were no defects recorded in the aircraft’s defect summary, the captain did not check the maintenance log, which was where the fan’s removal was recorded.

“Also, the captain reset a circuit breaker that had been opened to facilitate the fan removal without fully reviewing the maintenance documentation as per the operator’s flight crew operating manual.”

Since the incident, the operator has taken a range of steps to avoid a recurrence.

These include refining the terminology used by the engineering department to communicate aircraft serviceability, reviewing internal communication methods, and reiterating existing paperwork and circuit breaker resetting requirements.

“All tasks, including those that may seem innocuous, should be performed as though they are the last defense to ensure safe operation,” Dr. Walker said.

“The aircraft documents are the primary record of airworthiness, and this occurrence shows that thoroughly checking them remains an important control to determine if the aircraft can be operated.”

Read the ATSB report in full: “Cabin pressurization issue involving a De Havilland Canada DHC-8, VH-QQD, 30 km north of Perth Airport, Western Australia, on 20 November 2021.”

Content and photo credit: ATSB (Australian Transport Safety Bureau), “Safety steps taken after Dash 8 cabin failed to pressurize.” Publication Date: 20/01/2023.

Why is TapRooT® Training the top RCA training?

TapRooT® RCA has been designed for investigating seemingly simple problems that could have been worse (precursor incidents) by using a simple 5-step process. TapRooT® RCA can also be used to investigate major accidents by using the complete 7-step process.

- The 2-Day TapRooT® Root Cause Analysis Course teaches the essential techniques for investigating precursor incidents and fixing them to prevent major accidents.

- The Equifactor® Training Course also teaches how to use the TapRooT® techniques and Equifactor® Troubleshooting Tables to stop equipment problems.

- The 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Training teaches the complete 7-step TapRooT® process and techniques to investigate major accidents, serious environmental releases, fatalities, major plant upsets, and serious injuries, as well as simple incidents.

TapRooT® Training is what you need — a guided root cause analysis

TapRooT® Root Cause Analysis is global — and local — to meet your needs. If you would like us to teach a course at your workplace, please reach out here to discuss what we can do for you, or call us at 865.539.2139. Need other times or locations? Please see our full selection of courses.