Identifying Suspect/Counterfeit Items During Incoming Inspection: DOE

What happens when there’s a reason to identify suspect/counterfeit items — and how observant are you?

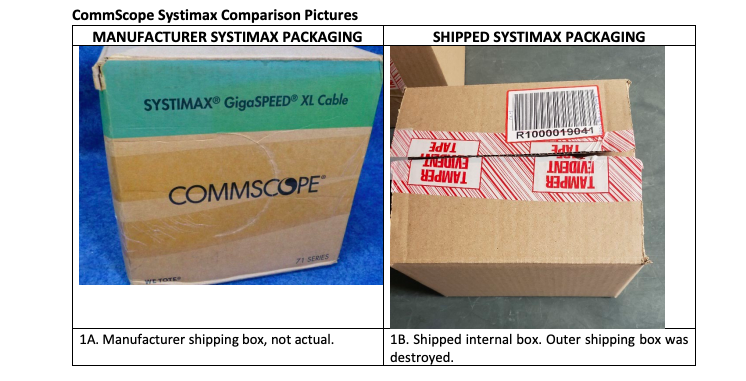

In May 2022, Ames National Laboratory’s Information Technology Department discovered unusual packaging for CommScope Systimax products, and this DOE (Department of Energy) report provides information to aid in the identification of suspect/counterfeit (S/CI) products.

Summary of lesson learned and best practice for identifying suspect/counterfeit materials

When unusual packaging is identified during the incoming inspection, the packaging and items should be inspected further to determine if the items are genuine, nonconforming, or suspect/counterfeit. Nonconforming items should be controlled and managed through coordinated procurement channels to reduce the risk of the items re-entering the supply chain.

Nonconformance Description

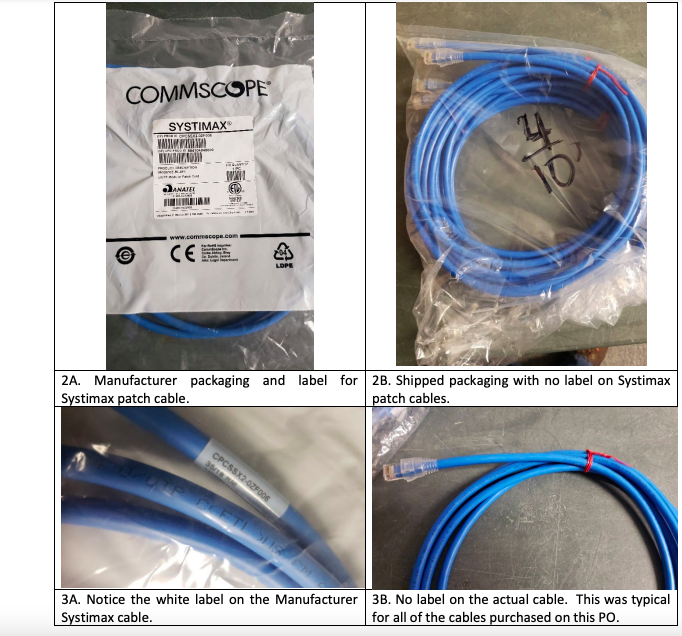

The Ames National Laboratory Information Technology Department purchased fifteen CAT6A patch cables of different lengths from Government Scientific Source. When the items arrived, the Information Technology staff discovered unusual packaging and the items were identified as nonconforming and potentially suspect/counterfeit.

In this case, the boxes were unmarked, and the cables were packaged in plain plastic bags without any labels. This type of packaging is uncharacteristic of CommScope products (see CommScope Systimax comparison pictures). The Information Technology Department notified the supplier and manufacturer and determined that these items were suspect. A nonconformance report was filed documenting the discrepancies on May 20, 2022.

Recommended Actions

1) Verify that packaging on components is typical of that provided by manufacturers. If discrepancies are identified, contact the manufacturer to determine if the packaging has been changed and provide examples or pictures of the packaging that you received. This will aid the manufacturer in determining if the items may be suspect/counterfeit.

2) Verify that components provided meet the requirements and standards that they were procured to meet. This could mean conducting in-depth visual inspections or additional testing to determine if there are any nonconformances to specifications. Having information such as test results, dimensional, or labeling discrepancies may also aid manufacturers in understanding if there has been a quality deficiency at one of their facilities or if they have a distributor that has been infiltrated by suspect/counterfeit products.

3) Verify that the manufacturer is aware of the issue if you have not contacted them prior to this step. Suspect/Counterfeit product may enter authorized distribution channels (such as in this case) through various means. It is important for manufacturers to understand if their authorized distributors may have suspect/counterfeit product infiltrations on their shelves, so that they can find and remove these products.

For more information regarding Suspect/Counterfeit Items, go to the DOE’s Suspect/Counterfeit and Defective Items website at https://www.energy.gov/ehss/suspectcounterfeit-and-defective-items.

Photo and content credit: U.S. Department of Energy, Office of Environment, Health, Safety, & Security, DOE OPENShare, Lesson ID: AMSO-AMES-SC-01062023, “Identifying Suspect/Counterfeit Items During Incoming Inspection – CommScope CAT6A Cables,” Originating Organization: U.S. Department of Energy, Ames National Laboratory.

Circumstances can crop up anywhere at any time if proper and safe sequence and procedures are not planned and followed. We encourage you to learn and use the TapRooT® System to find and fix problems.

TapRooT® has a team of investigators and instructors with years of extensive training ready to offer assistance worldwide. We also offer ongoing support to our clients through free newsletters and root cause tip videos, the root cause analysis blog, and our annual Global TapRooT® Summit.

Register for one of our courses. We offer a basic 2-day course and an advanced 5-day course. Contact us or call 865.539.2139 about having a course at your site or for further root cause analysis opportunities. We’re here to find solutions for you.

Contact us to discuss training your employees on-site. You may also call us at 865.539.2139 to speak to an instructor, schedule an executive briefing, or book on-site training for your team.