Your Hazards vs. OSHA Top 10 Violations (and Safeguard Analysis)

HAZARDS vs VIOLATIONS (And Safeguards)

• • •

OSHA publishes an annual list of the top 10 cited OSHA violations. Below is the 2018 list from the OSHA website.

- Fall protection, construction (29 CFR 1926.501) [related OSHA Safety and Health Topics page]

- Hazard communication standard, general industry (29 CFR 1910.1200) [related OSHA Safety and Health Topics page]

- Scaffolding, general requirements, construction (29 CFR 1926.451) [related OSHA Safety and Health Topics page]

- Respiratory protection, general industry (29 CFR 1910.134) [related OSHA Safety and Health Topics page]

- Control of hazardous energy (lockout/tagout), general industry (29 CFR 1910.147) [related OSHA Safety and Health Topics page]

- Ladders, construction (29 CFR 1926.1053) [related OSHA Safety and Health Topics page]

- Powered industrial trucks, general industry (29 CFR 1910.178) [related OSHA Safety and Health Topics page]

- Fall Protection–Training Requirements (29 CFR 1926.503) [related OSHA Safety and Health Topics page]

- Machinery and Machine Guarding, general requirements (29 CFR 1910.212) [related OSHA Safety and Health Topics page]

- Eye and Face Protection (29 CFR 1926.102) [related OSHA Safety and Health Topics page]

This got me thinking . . . do these violations relate to the biggest Hazards that U.S. companies face? Are these regulations good Safeguards that are failing? Or should companies be concentrating on removing the Hazards and avoid having to comply with the regulations?

Safeguard Analysis

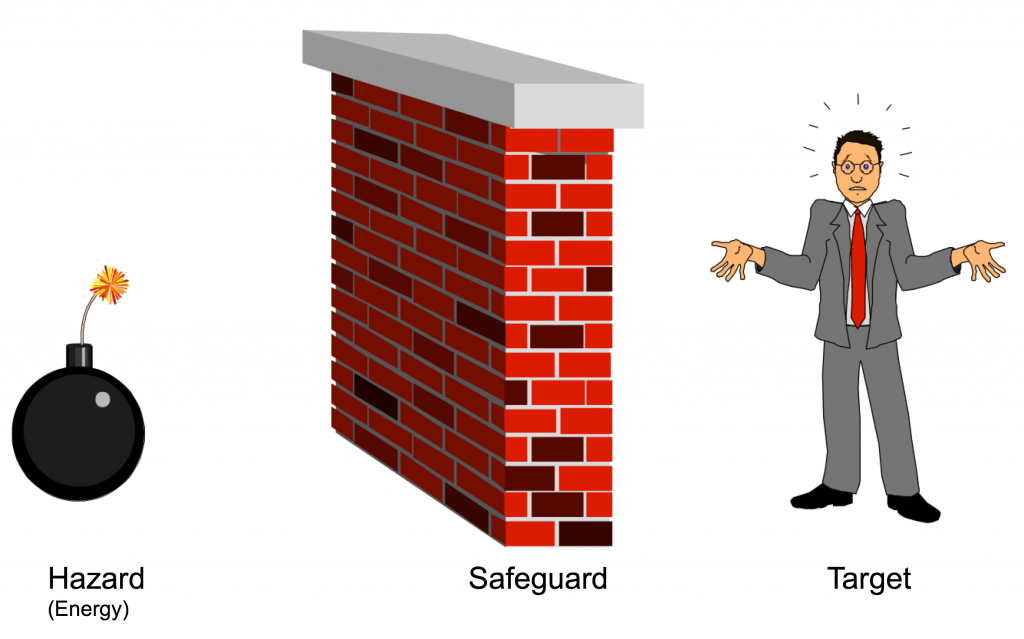

What is a Hazard, a Safeguard, and a Target? We often use this illustration to explain these concepts.

One thing you can do at your facility is to look for your top Hazards. Some or all of them may be covered by OSHA regulations. The regulations probably require Safeguards for human targets.

What is a Hazard?

But, what is a Hazard? This figure from our 5-Day TapRooT® Advanced Root Cause Analysis Course may help you understand.

A Hazard is some form of energy that people need to be protected from to avoid harm.

Which Safeguards Are Strongest?

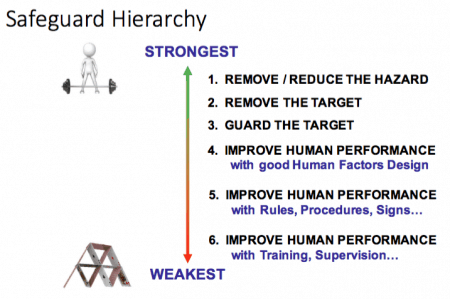

Think about the strength of the Safeguards you use for your biggest Hazards. Are they strong Safeguards or weak Safeguards?

We use the guidance below to “rate” the strength of a Safeguard.

The idea is, strong Safeguards will fail less frequently than weak Safeguards.

Thus, an easy-to-use product (good human factors design) is safer than telling people to be careful when using a dangerous product.

The controversial issue is how good are Safeguards on the Target (Personal Protective Equipment) vs. good human factors design and other Safeguards.

Obviously, by the guidance above, removing the Hazard or the Target is better than any kind of guard on the target. But, is PPE better than good human factors design, good rules and procedures, and good training and supervision?

That is a difficult question to answer. It depends on:

- The effectiveness of the PPE

- The ease of use of the PPE

- The availability of the PPE

- The training required to use the PPE

- The enforcement of the rule to use the PPE

- The supervisory emphasis of the use of PPE

Thus, Item 3 in the Safeguard Hierarchy, Guard the Target, often depends on the goodness of items 4, 5, and 6 on the Hierarchy as they apply to that particular PPE.

The only certain way to completely eliminate the risk is to remove the Hazard or remove the Target.

How Do You Use Safeguard Analysis to Improve Performance?

Do you know your facility’s greatest Hazards and have you checked the effectiveness of your Safeguards?

Do you audit your Safeguards to check that they are in place or being applied?

Do your supervisors know how to use Safeguard Analysis as part of their pre-job safety assessments?

Do supervisors use Safeguard Analysis and pre-job safety assessments to develop effective pre-job briefings?

Do you use Safeguard Analysis to check the effectiveness of your incident investigation corrective actions?

Do you require the strongest Safeguards as part of the corrective actions for high-risk incidents?

The right answers to these questions can help your facility improve safety performance.

Learn More About Safeguard Analysis

Now is a good time for you to learn more about Safeguard Analysis to solve real problems, get better results, and improve performance. Attend a 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Course and learn to develop better corrective actions that provide the strongest safeguards to future errors.

Here are some of the 5-Day TapRooT® courses coming up later this year:

Newcastle, Australia, November 11-15

Bogota, Colombia, November 18-22

Houston, Texas, November 18-22

Perth, Australia, November 25-29

Edmonton, Canada, December 2-6

Johannesburg, South Africa, December 2-6

For a complete list of upcoming public TapRooT® Courses, see:

https://www.taproot.com/store/Courses/.

We are also available to train you and your staff on-site at your workplace; contact us to discuss your needs. You may also call us at 865.539.2139 for any questions you may have.